Design Considerations for Custom Low Pressure Molding

Low pressure molding keeps electronics safe. It protects them from dust, water, and damage. It makes parts strong and solid. They do not crack or break easily. It is also a cost-friendly way to seal delicate parts. To make the best-molded parts, you need to plan well. Think about materials and design. Also think about how strong you need the parts to be. Picking the Best Mold Machine A mold machine shapes and forms materials. Picking the right one is very important. It must fit the size, type, and pressure needed for the job. A good machine makes strong, smooth, and neat parts. A lousy machine can cause weak, rough, or broken pieces. The machine should be easy to use. If it is too hard to control, mistakes can happen. A simple machine saves time and effort. A good machine also uses less energy. This helps save money and makes better parts. A strong and well-built machine lasts longer and needs fewer repairs. Choosing the Right Material The material used in molding is vital. Some are soft, some are hard. Low pressure molding often uses plastics that melt and flow easily. The right material makes parts strong and long-lasting. The wrong one might break or not stick well. Some materials bend easily. Others are stiff and strong. If a part must handle heat, it needs heat-resistant material. Some materials last longer than others. Picking the best material helps make better products that last. Making a Better Mold System A mold system shapes parts. A well-made system fills up smoothly. It cools evenly. It does not waste material. It does not trap air. Air bubbles can make parts weak. A sound mold system makes perfect parts every time. The mold should also be easy to clean and fix....

続きを読む "Is Low Pressure Molding Better for Sensitive Electronics

Low pressure molding covers delicate electronics like a soft shield. It keeps them safe from heat, dust, and damage. Some methods are too rough and break parts. Others do not protect enough. This method is just right. A unique material melts and flows over parts smoothly. It does not press too hard. When it cools, it forms a strong shell. This stops water, dirt, and damage. Many industries use this method. It helps electronics last a long time. Let's see why it is the best choice. Low Pressure Molding Keeps Tiny Parts Safe Small electronics are very delicate. They can break so quickly if not handled carefully. Low-pressure molding gently covers these tiny parts. It does not press too hard. Other molding methods use strong force. That force can damage circuits. When circuits break, the device stops working. Low-pressure molding applies a soft, even layer. It keeps everything safe. This method protects delicate devices. It helps them last longer. It keeps circuits, sensors, and chips from getting damaged. It is the best way to keep small parts safe. Uses Special Protective Materials Low-pressure molding uses unique protective materials. These materials are strong. They shield electronics from heat, water, dust, and dirt. Heat can cause electronics to overheat. Water can cause rust and short circuits. Dust can clog small parts. Dirt can make things stop working. The protective materials stop all these problems. They keep fragile parts safe. Even though the cover is challenging, it is gentle. It does not press too hard on the device. That makes it perfect for delicate electronics. It is excellent for medical tools. It is terrific for car sensors. It is great for factory machines. It protects electronics from harmful conditions. Low Pressure Injection molding Works With Smart Mold Systems New mold systems make low-pressure...

続きを読む "Sectors that Use Custom Low Pressure Molding

Some things need Low Pressure Moldings so they do not break or get hurt. These covers help things last a really, really long time! They keep things secure from bumps, water, and dirt. Big jobs like making cars, building big machines, and making tiny computer parts all use these. Without covers, things could break too fast! Let's learn more about who needs these covers and why they are so important! Low Pressure Molding Helps Phones & Computers Stay Strong Phones and computers have lots of tiny, tiny parts inside. These parts are super important because they make everything work. But these little parts can get hurt very easily. If water splashes on them, they can stop working. If dust gets inside, they can break. If they get bumped or dropped, they might stop working forever! That would be really, really bad! Low-pressure molding makes a super strong cover around these tiny parts. It wraps them up like a warm, safe blanket. It keeps them dry. It keeps them clean. It keeps them safe from bumps and drops. This helps phones and computers last a long, long time! That means people can watch their favorite videos, play fun games, and talk to their friends without any problems. Low Pressure Molding Helps Cars Keep Moving Cars have lots and lots of little wires and tiny parts inside. These parts help the car move, stop, and turn. They make sure the car's lights turn on. They make sure the engine works. But these little parts need to stay safe! If water gets in, they can stop working. If dirt gets inside, they can break. If something terrible happens to them, the car might stop moving! That would be super scary! It makes a strong, tough cover that keeps these little parts safe. It...

続きを読む "低圧成形とは何か?

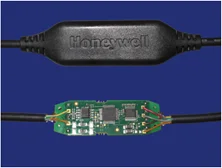

低圧成形とは何か、どのように使用されるのか、その工程 低圧成形は、私たちが日常生活で目にし、遭遇する技術である。低圧成形は黙々とその仕事をこなし、皆さんはおそらく何とも思っていないでしょう。QL-Customでは低圧成形について長年の経験がありますので、この記事で低圧成形の主なポイントをご紹介したいと思います。この記事では、低圧成形の工程と利点について、用途だけでなく環境についても深く掘り下げていきます。 低圧成形とは?低圧成形は、損傷や湿気、その他の外的影響を受けやすい部品を保護し、封止する技術です。配線やプリント基板などの用途が代表的です。ホットメルトと呼ばれる材料を使用し、専門機械を用いてポリマーを部品の周囲に封入します。 ホットメルト」と呼ばれるダイマー酸ベースのポリアミド材料は、熱可塑性プラスチックであり、特定の温度に加熱されると柔軟で可鍛性になり、貴重なコネクターや接続部の周囲に使用されます。 低圧成形と呼ばれる理由 低圧成形(またはLPM)とは、その名前が示すように、より業界標準的な圧力成形用途で使用される通常の圧力や極端な熱に部品が苦しむ可能性がある場合に使用される低圧プロセスや技術の使用です。繰り返しになりますが、低圧成形を必要とする主な理由は2つあります。 可鍛性 大きな要因の一つは、適用される熱可塑性プラスチックの粘性を高める必要があることです。粘性により、射出成形された材料は...

続きを読む "低圧成形

低圧成形 低圧成形の歴史 1972年:フランスIBMに初めて採用される。1987年:Eruope自動車用電子部品成形開始 1993年:フランス自動車用ワイヤーハーネス産業用 1995年:自動車用として幅広く使用され、電子部品にも拡大 2000年:PCB、センサーデバイス、コネクター用として使用される。After2000:2000年以降:世界の産業界で幅広く使用されています。 低温成形とは 低圧射出成形は、非常に低い射出圧力で封止材を金型に注入し、素早く固化させるパッケージングプロセスです。絶縁性、耐熱性、耐衝撃性、防湿性、防水性、防塵性、耐薬品性を実現する。適用:回路基板、電子コネクタ、ワイヤーハーネス、バッテリー、スイッチ、LEDライト、コイルなど。 利点 射出サイクルが短い 樹脂材料 環境保護 コンパウンドを混合する必要がない 熱可塑性プラスチックは、固化時間を必要としない 高い信頼性 シンプルな金型設計 オーバーモールド部品の利点 防水 絶縁 耐衝撃性 耐温度性 耐薬品性 スクラップ 環境に害を与えない PA PA材料要素の特性 プラスチック樹脂要素 ダイマー酸ベースのポリアミドアミン ダイマー酸ベースのポリアミドアミンは、ジアミンと二塩基酸との重縮合の結果である。低圧プラスチック樹脂の原料は? 一般的な農産物から抽出されたダイマー酸 ヒマシ油 コーン油 亜麻仁油 ピーナッツ油 植物油 トール油 低圧材料の色は何ですか 材料は粒状である 一般的に黒色または琥珀色 他の色にすることができます 私たちは次のような材料を提供します Inejction 圧力1〜200psi(0〜60kg) 成形温度160℃〜230℃ ICおよびコンポーネントの特性を保護 Charactor PA/PO/PET/PUR QL-カスタム十分な在庫 QL-カスタム プロのアドバイス Envirmetal 良い絶縁特性、難燃性、耐腐食性 低圧成形材料の選び方は? ...

続きを読む "