Sectors that Use Custom Low Pressure Molding

Some things need Low Pressure Moldings so they do not break or get hurt. These covers help things last a really, really long time! They keep things secure from bumps, water, and dirt. Big jobs like making cars, building big machines, and making tiny computer parts all use these. Without covers, things could break too fast! Let's learn more about who needs these covers and why they are so important! Low Pressure Molding Helps Phones & Computers Stay Strong Phones and computers have lots of tiny, tiny parts inside. These parts are super important because they make everything work. But these little parts can get hurt very easily. If water splashes on them, they can stop working. If dust gets inside, they can break. If they get bumped or dropped, they might stop working forever! That would be really, really bad! Low-pressure molding makes a super strong cover around these tiny parts. It wraps them up like a warm, safe blanket. It keeps them dry. It keeps them clean. It keeps them safe from bumps and drops. This helps phones and computers last a long, long time! That means people can watch their favorite videos, play fun games, and talk to their friends without any problems. Low Pressure Molding Helps Cars Keep Moving Cars have lots and lots of little wires and tiny parts inside. These parts help the car move, stop, and turn. They make sure the car's lights turn on. They make sure the engine works. But these little parts need to stay safe! If water gets in, they can stop working. If dirt gets inside, they can break. If something terrible happens to them, the car might stop moving! That would be super scary! It makes a strong, tough cover that keeps these little parts safe. It...

阅读更多 "Are there Benefits of Custom Plastic Injection Molding

Machines have lots of little parts. Some of these parts are made of plastic. People use a big machine to melt plastic and press it into a shape to make plastic parts. This is called Custom Plastic Injection Molding! Plastic moulding helps make parts the same size and shape every time. That way, every part fits just right. It also costs less than making parts by hand. Plastic parts made this way are strong and last a long time. Let’s learn why plastic moulding is so helpful! How Do We Make Plastic Pieces That Fit Together? Plastic pieces need to fit together like a puzzle! They cannot be too big. They cannot be too small. They need to be just right! Plastic injection moulding makes every piece the same shape and size. This means no mistakes! No wobbly parts! Every piece will match and work perfectly, just like magic! Factories use this method to make substantial plastic parts for many things, like toys, machines, and cars. Custom Plastic Injection Molding: Make So Many Pieces Making plastic pieces this way helps save lots and lots of money. First, we make a unique mold. Then, we can use it repeatedly to make thousands, even millions, of pieces! We do not have to wait a long time for each one. We can make so many pieces super fast! This also means we do not waste extra plastic, and that helps save even more money. Less waste is better for the earth, too! Strong and Tough Plastic Pieces That Last a Long These plastic pieces are not weak! They are powerful! They do not break easily. They do not melt when it is hot. They do not crack when it is cold. They stay in good shape for a very, very long time! That...

阅读更多 "Benefits of Using a Custom Wire Harness in Electronics

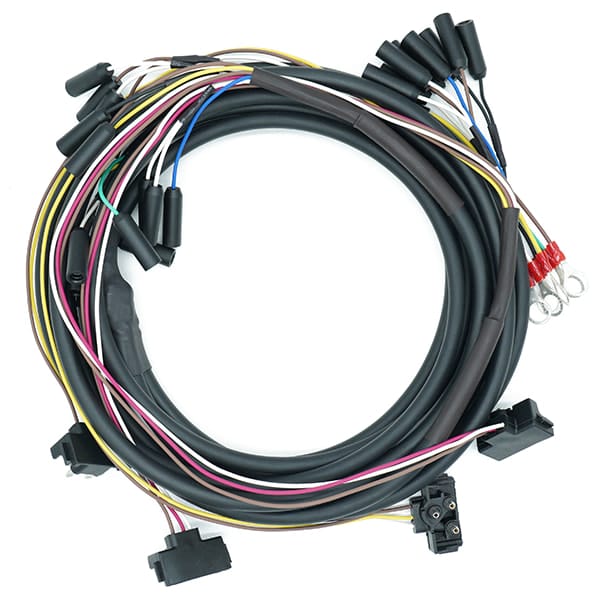

Wires are tiny ropes that carry power to machines. When wires are all over the place, they get messy and can break. If a wire breaks, the machine may stop working. That is bad! A Custom Wire Harness is a way to keep wires safe. The wires stay in one place and do not get tangled. That means machines can work better and last longer. It also helps people stay safe. Let’s learn why wire bundles are super helpful for machines. A Custom Wire Harness Helps People Save Time A wire harness bundle is a bunch of wires in one neat and tidy group. When wires are all loose, they can get messy and complicated. But they stay nice and neat when they are in a wire bundle. This makes it so much faster to set things up. People do not have to guess where each wire goes because everything is already in the right spot. It also helps to stop mistakes. If the cables are not mixed up, everything will work just right. That means no problems, no worries, and no time wasted! Custom Wire Harness Keeps Wires Neat If wires are loose, they can turn into a big, big mess. They can twist, tangle, and get all mixed up. That makes it hard to know which wire goes where. A wire bundle stops this from happening. It keeps all the cables in one place, all neat and tidy. This makes it so much easier to work with. It also helps if something breaks because people can find the correct wire fast. No more guessing or searching—everything is right where it should be! Custom Wire Harness Keeps Wires Safe from Water Wires need to stay safe to work the right way. They can break if wires get wet, dirty,...

阅读更多 "How do OBD Cables help troubleshoot vehicle problems

OBD cables are tools to help cars. They connect the vehicle to a machine. This machine finds problems inside the car. It shows codes that tell what is wrong. This makes fixing the vehicle easy and fast. OBD wires save lots of time. They help mechanics fix cars quickly and satisfactorily. What Are OBD Cables and How Do They Help Your Car? OBD connectors are little plugs that help find what is wrong with your car. They are like a bridge between your vehicle and a tool that checks for problems. The car’s computer saves clues when something is wrong. The OBD connector lets the tool read these clues. This helps mechanics, or even you, know what needs fixing. It makes fixing cars faster and easier. Without this, it would take a lot more time to figure out what is wrong. How Do OBD Connectors Help Find Car Problems? Your car has a little computer inside. This computer checks if everything is working fine. If something is broken, it saves a code. The OBD plug helps read this code. When you connect the plug, the tool shows the code on its screen. It’s like the car is talking to you, telling you what’s wrong. This makes fixing the vehicle easy. It saves time because you don’t have to guess. It helps everyone, from drivers to mechanics. Why Are OBD Power Pins So Important? The OBD power pins are small parts, but they do a big job. They give power to the tool that checks your car. Without these power pins, the tool will not turn on. That means it won’t work. The pins make sure the tool has the energy it needs. If the pins are broken, you can’t read what’s wrong with the car. They may be tiny, but...

阅读更多 "Can Technomelt Hotmelt Resins be used for automotive works

Technomelt hotmelt resins are like glue for car parts. They stick parts together very well. They can handle lots of heat and stay strong. They fill spaces and stop leaks. This helps make cars safer and better. These resins work in hard places and last a long time. They keep car parts safe and in place. What Are Technomelt Hotmelt Resins? Resins are like sticky glue. They hold things together. Hotmelt resins are robust and work well. They melt when they are heated up. When they cool down, they keep things tightly. These resins are perfect for cars. Cars have many parts that need to stay together. The parts must remain strong, even when it is very hot or very cold. They also must hold when cars move and bump around. Technomelt resins help cars stay strong and work like they should. They are super helpful for building cars and keeping parts in place. Why Are Technomelt Hotmelt Resins Good for Cars? Technomelt hotmelt resins are strong and tough. They can handle heat when it is very hot outside. They also work when it is freezing cold. Cars move a lot and shake on bumpy roads. These resins do not break or fall apart. They seal gaps to stop water, air, or dirt from coming inside the car. This makes cars quiet and more comfortable. Car makers like Technomelt resins because they work very fast. They help save time when cars are being built. These resins make cars better, stronger, and safer. How Do Technomelt Resins and Epoxy Resins Compare? Epoxy resins are strong, too. They are great for some jobs. However, epoxy resins take a long time to harden. You have to wait before they are ready. Technomelt resins are faster. They work right away when they are heated....

阅读更多 "哪些部门最适合使用电缆组件

电缆组件将电线连接在一起。它们用于许多工作。汽车使用它们为车灯和系统供电。飞机需要它们来保证一切安全运行。工厂用它们为大型机器提供动力。这些组件可以保护电线免受损坏。它们可以防止短路等问题。它们坚固耐用,使用寿命长。医院也将它们用作医疗工具。电缆组件在很多方面都有帮助。它们能保证安全和正常工作。许多行业每天都在使用它们。电力系统:电缆组件带来电力 电缆为家庭带来电力。它们帮助电灯打开。这些电缆还帮助机器工作。没有这些电缆,我们就没有电力。电缆组件就像连接所有部件的小帮手。它们确保电力能够安全地输送到我们的家中。这些小电缆帮助我们的世界保持光明。汽车工业:帮助汽车行驶,保证我们的安全 电缆组件帮助连接从发动机到车灯的所有部件。这些电缆确保汽车能够行驶,也确保我们能够在夜间看到汽车。电缆组件有助于保持汽车正常工作。它们还能确保车灯、传感器和制动器在我们需要时正常工作,从而保证我们的安全。没有这些电缆,我们的汽车就无法行驶,也无法保证我们的安全。工业设备:工厂中的机器正常工作 工厂中的大型机器使用电线组件。这些电缆为机器提供动力。如果电缆断裂,机器就会停止运转。机器停了,工厂的工作也就停了。电缆组件至关重要,因为它们能保证一切运转。它们帮助机器更好地工作,使用寿命更长。如果这些电缆不工作,工厂就无法生产任何东西。消费电子产品:让这些电缆工作良好 电缆组件用于我们的电话、电视和电脑中。这些...

阅读更多 "定制线束如何帮助我们

定制线束可保持电线整齐。它可以防止电线变得凌乱。这有助于小工具更好地工作,使用寿命更长。定制线束恰到好处。它可以节省空间,看起来也很整洁。它还能让固定电线变得简单。这些线束可用于汽车、飞机和小工具。它们能保护电线免受损坏。线束是一个明智的选择。它能保证一切工作顺利进行。它还能让小工具使用起来更安全。整齐的电线意味着问题更少,小工具的寿命更长。定制线束有助于使设备正常工作 线束就像一个特殊的电线盒。它将许多电线固定在一起。电线保持在原位,不会丢失。这有助于设备工作。您可以在汽车、机器和其他物品中使用线束。它有助于保持整洁。电线不会纠缠在一起。定制线束是确保一切正常工作的简单方法。定制线束如何节省时间 线束非常有用。它能将所有电线固定在一起。线缆不会杂乱无章。您不需要弄清楚哪根电线放在哪里。一切都恰到好处。电缆已经准备好。您可以快速开始工作。节省时间。当电线都在一起时,工作就容易多了。线束套件能让您更快地完成工作。布线专业人员如何制作完美的线束 布线专业人员帮助制作最好的线束。他们能确保电线恰到好处地适合您的项目。您不必担心电缆该放在哪里。线束可以满足您的需要。它能帮助您在工作中不出差错。它是为您量身定做的。安全简便....

阅读更多 "定制线束

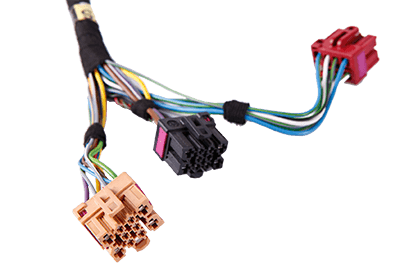

定制线束,它是什么,类型,区别,应用 从 QL-Custom 更好地理解:线束、电缆组件和电缆束 在 QL-Custom,我们每月都有线束组件知识培训。我们的一些客户,甚至是我们的竞争对手,都不了解定制线束、电缆组件和电缆束之间的真正区别。今天,我们将为您提供简单的识别方法。 在讨论之前,我们先要明确什么是电线,什么是电缆。 挂钩电线是带有绝缘层的单根电线,有单色和双色之分;它们与导体无关;电缆是多根单根电线捆绑在一起,带有塑料护套。有屏蔽或无屏蔽。 好了,现在你已经清楚什么是电线,什么是电缆了,你也可以猜到我接下来要讲什么了! 线束是不包括多条电缆的线束,包括组装成一套的不同电线、连接器和端子。 因此,电缆组件现在也很清楚了 电缆组件,只包括至少一根多芯或多于一根的电缆、连接器、端子或焊接电线,并将它们过度成型为一套。 您现在明白电缆线束了吗? 您可以致电 David 讨论更多问题。+86 13790139296 定制电缆和线束组件 应用 计算机 计算机线束,也称为电缆束、电缆组件、布线组件或布线织机,是电线、电缆和其他组件的系统化和有组织的排列,用于传输电...

阅读更多 "Why Custom Over-Molded Cables Last Longer and Work Better

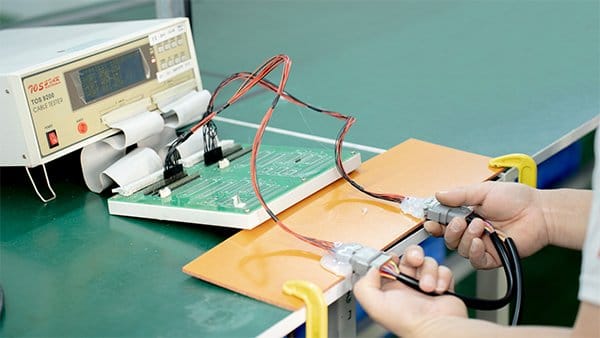

At QL-Custom Technology Limited, we are dedicated to pushing the boundaries of cable assembly technology. We provide custom over-molded cable assemblies and wire harnesses for various applications. Our company excels in creating seamless, durable cables that integrate wire and connector into a single, reliable unit. Using cutting-edge manufacturing processes, we produce custom-molded wires to meet the rigorous demands of industries worldwide. What are Over-Molded Cables? Over-molded cables are complete assemblies that combine the wire and connector into a singular, robust piece. The process involves placing the cable assembly inside a mold cavity, where molten plastic is injected, creating a sealed protective coating over the cable. This innovative manufacturing method enhances the cables' durability, flexibility, and longevity. At QL-Custom, our modern facilities, which include warehousing, engineering, production, and support services, ensure that every product meets the highest standards. We specialize in various plastic molding products, including GPS trackers, vacuum cleaner parts, speaker frames, and molded connectors. Our custom-molded - cables have earned a reputation for reliability in the automotive and solar power industries, with solutions tailored specifically for each customer. Our team works directly with you, guiding the design and production process to meet your specifications. After production, all products undergo rigorous testing to meet your needs and exceed industry standards. Types of Molded Cables We offer a variety of molded cables designed for specific applications, ensuring high performance and reliability across different industries: Custom Molded - Cables: Tailored solutions to meet unique customer requirements, offering flexibility in design and functionality for any application. Rubber Molded - Cables: These are highly flexible and durable cables, ideal for environments with high stress, vibration, or frequent movement, ensuring long-lasting performance. Plastic Molded - Cables: Cost-effective molded cables that provide excellent strength, durability, and protection for everyday applications in various industries. Waterproof Molded -...

阅读更多 "线束制造商

线束制造商 QL-Custom Technology Limited 站在线束制造的最前沿,专业生产各种产品,包括线束组件、线束、线束解决方案和定制线束。我们精通于精心制作高质量的线束,其特点是采用热固性或热塑性材料制成保护套。这些保护套在保护电线免受环境危害和潜在磨损方面发挥着关键作用。 我们坚定不移地执行严格的质量标准,为电子、医疗、汽车、电信、军事、清洁能源和其他高精密行业提供定制线束。作为一家杰出的全球合同制造商,我们的创新解决方案能满足原始设备制造商(OEM)和各行各业的独特需求。 在 QL-Custom Technology Limited,我们的专业领域延伸到包覆成型电缆组件和线束,确保为电线提供最高级别的保护。我们的产品种类齐全,包括线束组件、电池电缆和根据客户具体要求定制的电缆组件。 我们拥有一支敬业、经验丰富的全球员工队伍,提供塑料成型、低压成型(PCB 套塑)和盒装解决方案等增值服务,在行业内处于领先地位,我们为此感到自豪。我们的综合专业技术横跨多个领域,包括但不限于数据传输、压接端子、光纤和光纤。 无论是满足尖端自动驾驶技术的需求、促进太阳能设备的安装,还是提供消费电子产品的解决方案,QL-Custom Technology Limited 都是您值得信赖的合作伙伴。我们致力于提供一流的线束和电缆组装解决方案,以满足不断发展的行业需求。 选择 QL-Custom Technology Limited,我们将为您提供尖端的技术、可靠的产品...

阅读更多 "