The design logic of Coiled Cable

By wpname 玩得好 / 2024年10月24日

Coil Cable Design, Manufacturing, Length Calculation and Precautions

1. What is a Coiled Cable ?

A Coiled cable, also known as a retractable coiled cord or spiral cable, is a type of electrical cable that can stretch and retract like a Coils.

The prototype of the coil cable is actually a straight cable. The straight cable is wound around a fixed-size jig rod by winding, and the clamps on both sides are used to clamp the wire. Then it is put into the oven and baked for a certain period of time. It is taken out to form a coil cable.

2. Calculating the Real Length of a Coiled Cable

1. Determine the Structure:

Understand the number of coiled sections and straight sections that make up the Coiled cable.

2. Measure the Coil Parameters:

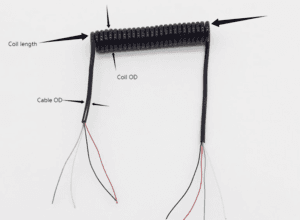

Coil length: we need to be clear the coiled part length, from one pc coiled cable

L=350mm

Coil ID : Measure the coiled part OD=15mm this parameter determines the fixture stick’s OD

Coil OD: Measure the coiled part OD=25mm

Cable OD: Measure the cable OD5.0mm

Then we can work out the cable coiled part how many coils. Use the coiled part length/Wire OD 350/5.0=70coils

Counting 1 coil length = πD= 3.14 X (25mm-5.0mm)=62.8mm (‘cause we can’t use the max OD to count the Circumference )

1 coil 62.8mm X 70 coils = 4396mm+the both ends lengths is the one pc cable real length

Note that the measurement method is relatively simple and intuitive but may have some errors. The formula calculation method requires accurate measurement of the structural parameters of the Coiled cable, and the calculated result is only an approximation. In practical calculations, choose the appropriate method based on the specific situation.

4. The Coiled Cable’s straight part orientation on both side

The main exit directions of Coiled cables are as follows:

I. Straight Exit- 180degree with the coil part

The Coiled cable extends straight out from one end. This exit direction is the most common and intuitive, suitable for situations requiring a neat spatial layout, such as data cables for electronic products that extend straight out from the side of the device for easy connection to external equipment.

II. Multi-Angle Exit – Vertical with the coil part

Oblique Exit: The Coiledcable extends at a certain oblique angle. In some special usage scenarios, due to the placement of the device or usage requirements, the Coiledcable may need to exit obliquely to better adapt to space limitations or operating habits.

Curved Exit: The Coiledcable can exhibit a certain curved shape as it extends. For example, in some wearable devices, the Coiled cable may exit in a curved manner to conform to the curves of the human body or adapt to the special structure of the device, ensuring connection stability and wearing comfort.

5. Coiled Cable Manufacturing Process

The manufacturing process of Coiled cables varies depending on the materials and intended use. The general process is as follows:

Material Preparation:

Select appropriate wire jacket materials, such as TPR/TPE/PU/PVC, along with Coilss and other accessories.

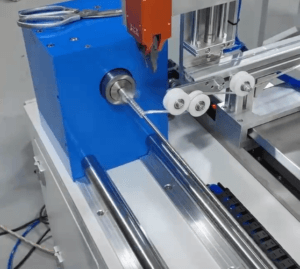

Wrapping:

Wind the wire around a winding rod, paying attention to the tightness and uniformity of the winding.

Baking:

Place the wound rod in a baking chamber to set the shape of the wire. The baking temperature and time depend on the material and specifications of the wire.

Cooling:

Remove the baked Coiled cable and allow it to cool. This can be done through natural cooling or forced cooling with a fan or other equipment.

Reversing:

Reverse the cooled Coiled cable to increase its elasticity and durability.

Second Baking:

Place the reversed Coiled cable back into the baking chamber for further baking to further set the shape of the wire.

Cooling and Shaping:

Remove the baked Coiled cable and allow it to cool and set its final shape. This can be done through natural cooling or forced cooling with a fan or other equipment.

Testing:

Test the finished Coiled cable, including tensile testing, elasticity testing, and durability testing, to ensure that its quality meets the requirements.

It is important to note that the manufacturing process of Coiled cables requires strict control of parameters such as temperature, time, and pressure to ensure quality and performance. Safety precautions should also be taken during the manufacturing process to prevent accidents.

6. The main benefits of Coiled cables are:

Retractility:

They can be stretched to different lengths as needed and automatically retract when not in use, saving space and making them easy to carry and store. For example, when using headphones or data cables, they prevent tangling and are easy to store.

High Durability:

Made with high-quality materials and a reasonable structural design, they can withstand a certain amount of tensile force and bending cycles, are not easily damaged, and have a long service life. They are particularly suitable for connecting devices that are frequently moved or used.

Flexibility:

They can adapt to different usage environments and bending angles, are not easily broken, and can be used flexibly even in narrow spaces or complex usage scenarios.

Wide Range of Applications:

Due to their unique properties, Coiled cables are widely used in mobile devices such as automobiles, machinery, and instruments, as well as in mechanical equipment, electronic devices, mining construction, airport ground facilities, and other fields. In these areas, the high stretchability and resilience of Coiled cables make them an ideal choice, especially where cables need to be frequently bent, stretched, or subjected to mechanical stress.

7. Selection of Coiled Cable Outer Sheath: PVC, TPE, TPU – Description of Advantages and Disadvantages

In Coiled cables, PVC, TPE, and TPU outer sheath materials each have their advantages and disadvantages. Here’s a detailed introduction:

PVC (Polyvinyl Chloride)

Good Flame Retardancy and Insulation: Effectively prevents safety issues such as fires caused by short circuits, ensuring safe use, and is commonly used for wire and cable sheathing. For example, in ordinary indoor appliance connection cables, PVC Coiledcables provide good insulation protection.

Good Acid and Oil Resistance: Can resist corrosion from acids, oils, and other chemical substances to a certain extent, making it suitable for environments that may come into contact with mild chemicals. For example, it is often used in equipment connection cables near non-highly corrosive chemicals in factories.

Easy to Process and Modify, Low Cost: Relatively simple processing technology, and its flexibility and hardness can be adjusted by adding different plasticizers to meet different needs. The raw material price is relatively low, reducing production costs. For example, in large-scale production with high cost control requirements, PVC Coiledcables are a more economical choice.

TPE (Thermoplastic Elastomer) ,TPU, PE

Advantages

Excellent Elasticity and Abrasion Resistance:

Has excellent resilience, can quickly return to its original shape after stretching or bending, and has good abrasion resistance, allowing for long-term use without losing performance. It is very suitable for Coiledcables that require frequent stretching and bending, such as earphone cables and data cables.

Soft Texture:

Soft texture, comfortable to the touch, adaptable to various shapes and stress conditions, and does not cause discomfort during use.

Good Chemical Resistance:

Can resist corrosion from various solvents, fuels, and chemicals, has good stability, and is suitable for environments that may come into contact with different chemicals.

Low Shrinkage:

Low shrinkage rate, suitable for producing high-precision products, and can ensure the dimensional stability and consistency of Coiledcables.

Simple Processing Technology:

Can be processed through various methods such as injection molding, extrusion, and calendering, resulting in high production efficiency and relatively low processing costs.

8. Quality of Coiled Cables

The quality of Coiled cables can be evaluated from the following aspects:

I. Appearance Quality

Outer Sheath Material: High-quality Coiledcable sheaths should be smooth, free of obvious defects, and free of graininess. PVC sheaths should have uniform color and be free of black spots or impurities. TPE and TPU sheaths should have good elasticity and softness and a smooth surface.

Wire Diameter Uniformity: The wire diameter should be uniform and consistent, without uneven thickness. This not only affects the appearance but also relates to the performance stability of the Coiledcable.

Connector Quality: The connector should be firm, secure, and tightly connected to the main body of the Coiledcable. Metal connectors should be free of rust and oxidation, and plastic connectors should be free of cracks and deformation.

II. Performance Quality

Retractility: This is a key performance characteristic of Coiledcables. High-quality Coiledcables should have good retractable performance, be able to easily stretch to the desired length, quickly return to their original shape after release, and maintain performance after multiple stretches.

Elasticity: Coiledcables with good elasticity are not easily deformed during use and can maintain a stable length and shape. The quality of elasticity can be judged by stretching the Coiledcable and observing its rebound speed and degree.

Durability: Includes tensile strength, bending performance, and abrasion resistance. It should be able to withstand a certain amount of tension and bending without breaking, and the outer sheath should not be easily worn under frequent use and friction.

Conductivity: If the Coiledcable is used to transmit current or signals, it should have good conductivity. Conductivity can be judged by measuring the resistance value to determine whether it meets the requirements.

In summary, the quality of Coiled cables can be judged by comprehensively considering their appearance, performance, and safety aspects. When choosing Coiled cables, select reliable products based on actual needs to ensure effectiveness and safety.