Certified Quality in Pre-Made Harnesses

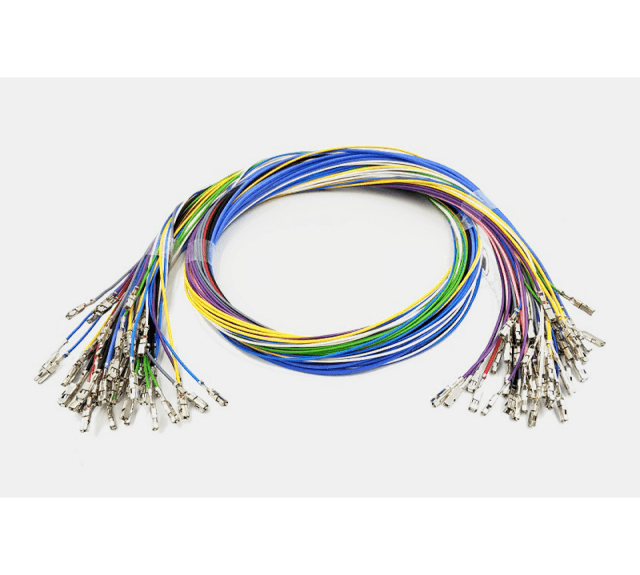

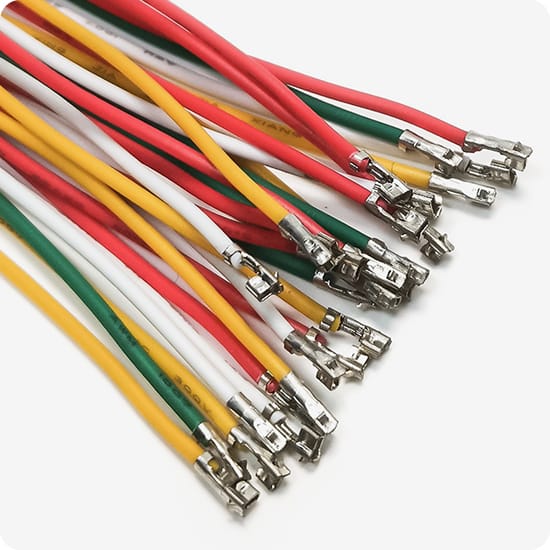

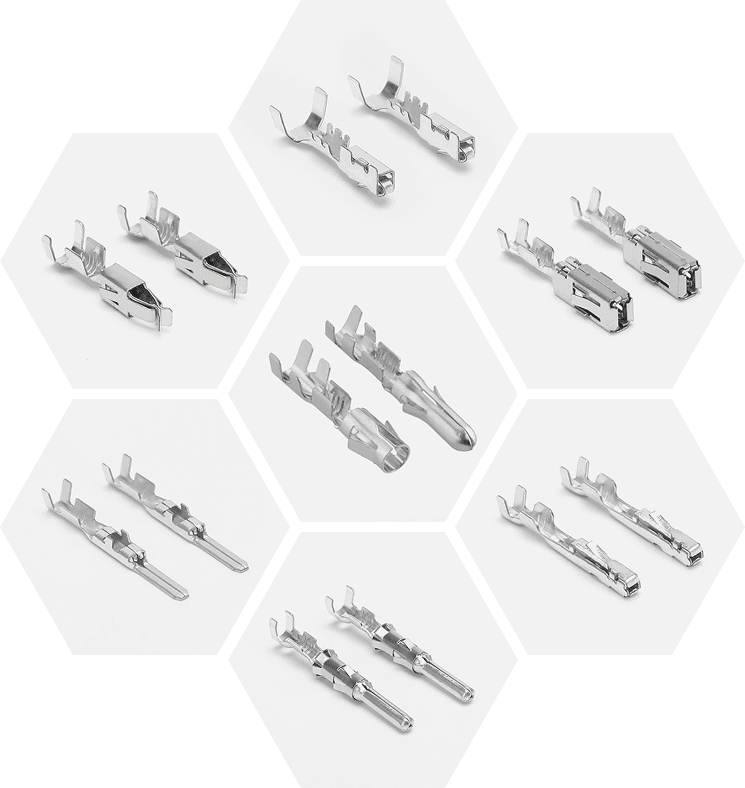

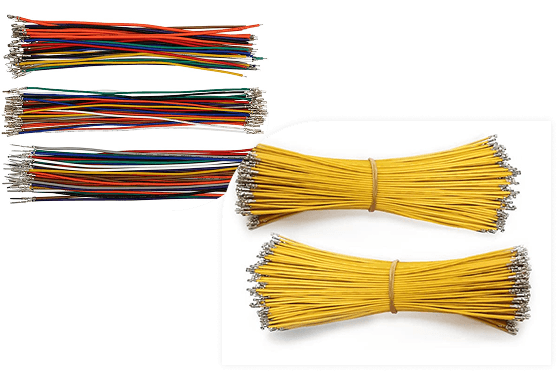

If you need pre-terminated harnesses, QL-Custom Technology Ltd. is a wise choice. We have many years of skill and a strong record of on-time work. Our team helps you from your first idea to the final test. We keep a big stock of wires and ends (AMP, JST, TE, etc.) so we can build your harness quickly, but still with care. Each harness is built to match your plan and checked individually. Each crimp and wire is tested before shipping. We focus only on harnesses, so our team has deep knowledge. You will always talk to someone who understands design and parts. In short, QL-Custom gives you safe, strong, and stress-free pre-terminated harnesses. Contact us today to get your harness made right the first time.