Cost Efficiency Through Reduced Maintenance

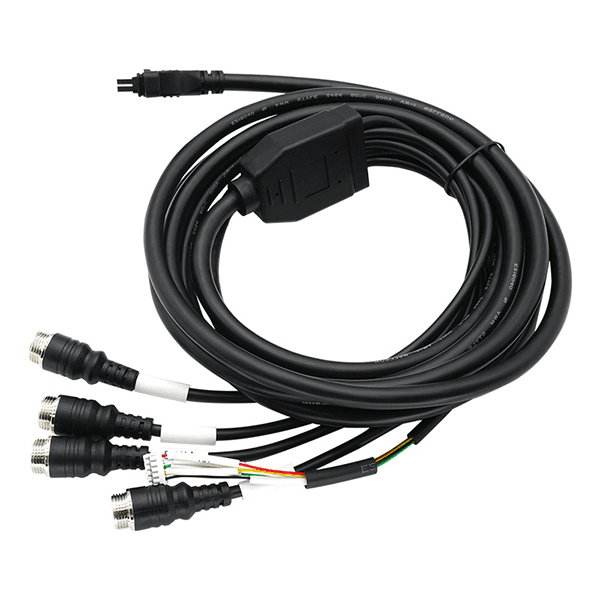

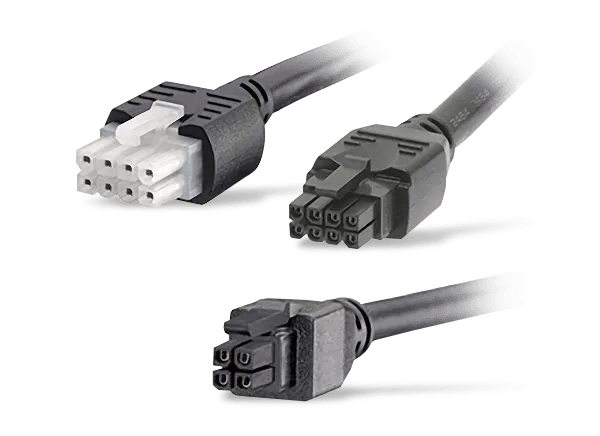

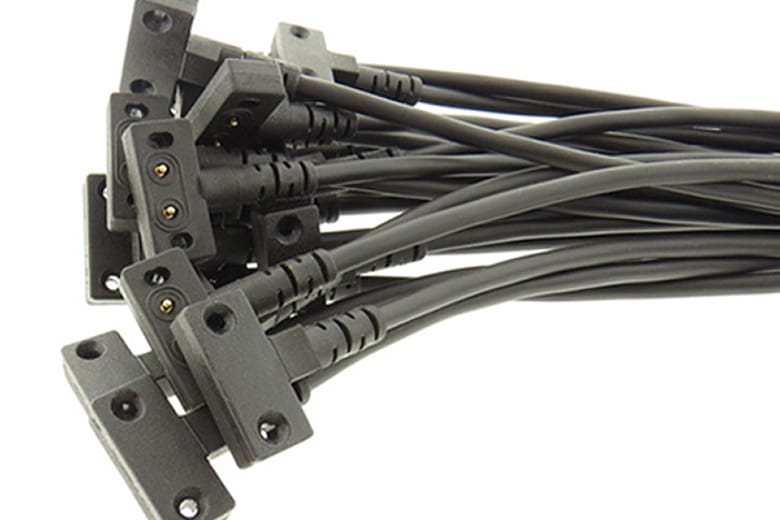

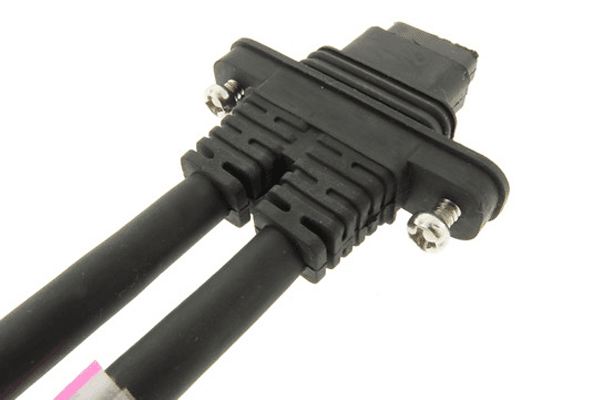

Overmolded wire harnesses can cost more initially, but they save much money later. In a standard cable, the point where the cable meets the connector is often the weakest spot. In an overmolded wire harness, that part is covered in strong, thick plastic, so it is tough to break. This means fewer fixes, fewer replacements, and fewer times when the machines have to stop working. These overmolded wire harnesses can last for many more years compared to standard cables. This saves repair costs, lowers warranty claims, and keeps work going without delays. Some designs can be used in many machines, so you do not need to store as many spare parts. Even though they may cost more initially, they quickly pay for themselves with the money saved over time.