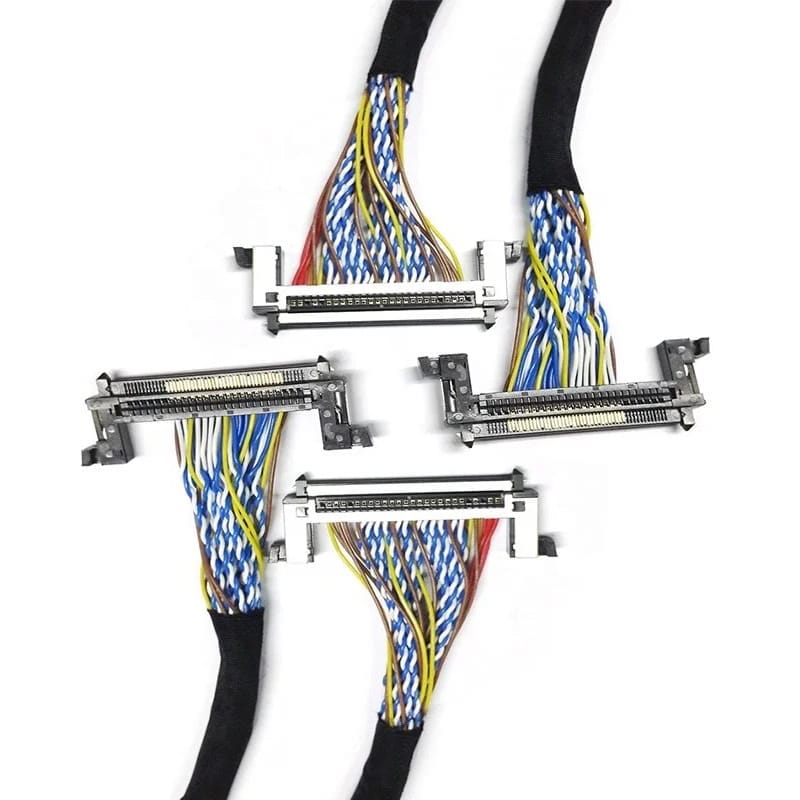

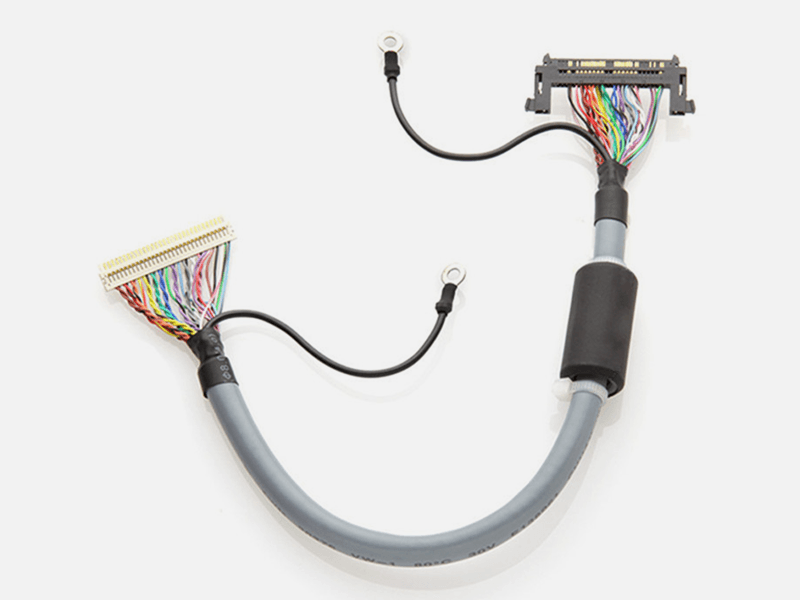

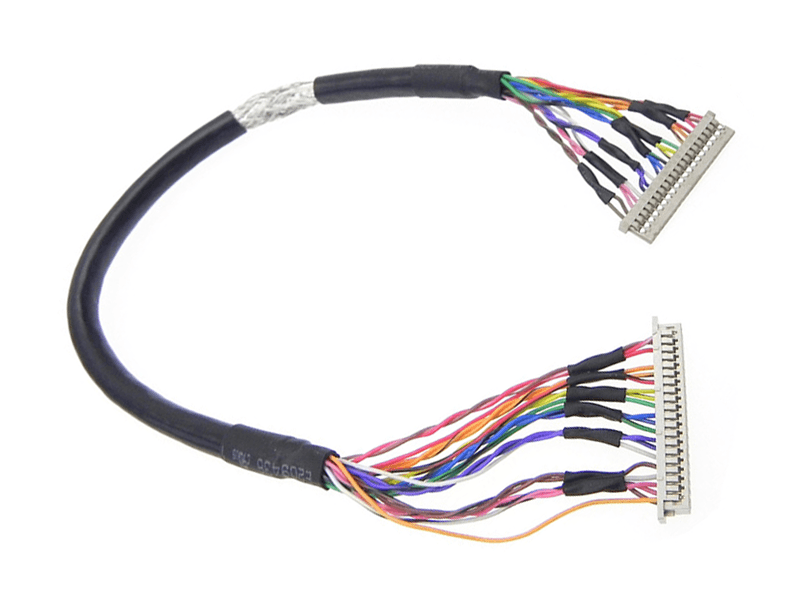

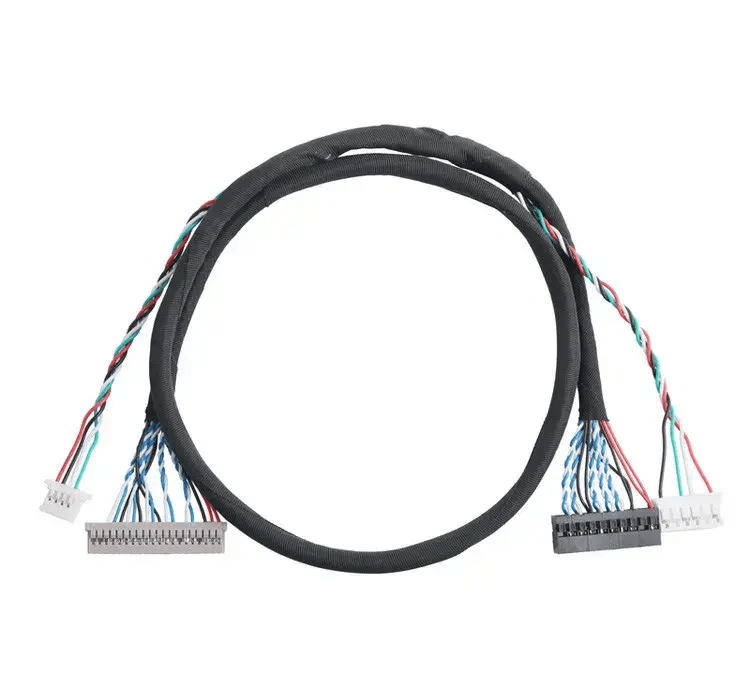

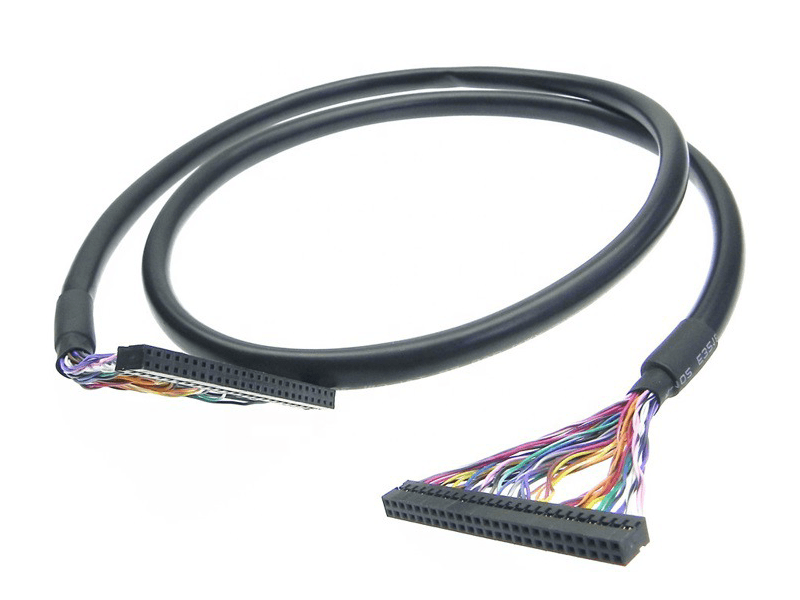

Custom LVDS Cable assembly

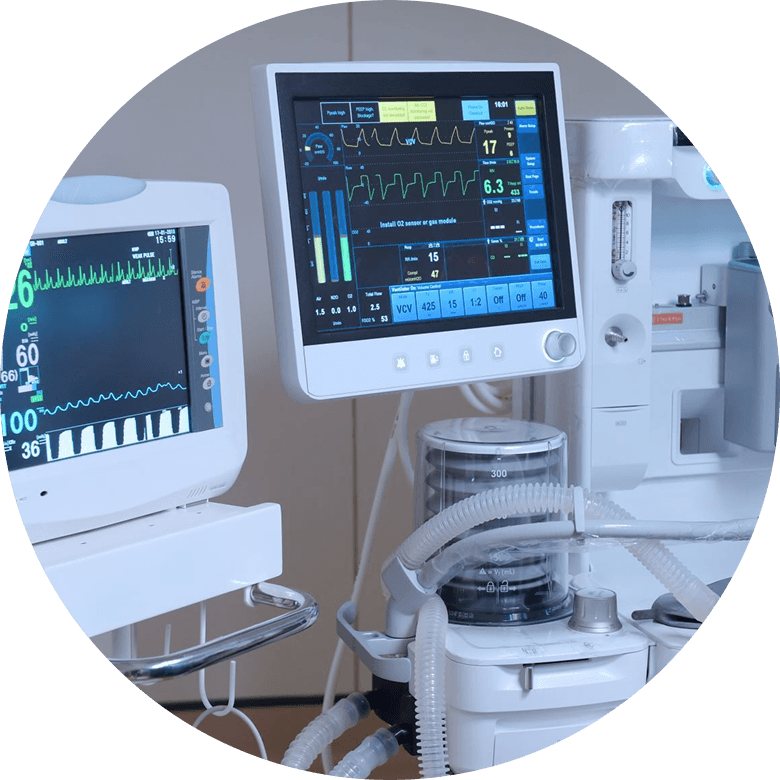

LVDS means Low-Voltage Differential Signaling. LVDS cable assembly is a specialized cable designed for high-speed data transfer. They use pairs of copper wires. Each pair sends one signal using two opposite sides. This helps block noise and outside interference. Due to this design, LVDS cables are ideal for high-resolution screens. You can find LVDS cables inside laptops, TVs, factory screens, and car displays. These cables must be made with great care. Each wire pair must have the same length and a steady 100-ohm impedance. If the cable is poorly made, the screen may flicker or lose signal. At QL-Custom, our team designs and builds custom LVDS cable assemblies that deliver sharp images and a long service life, even in demanding conditions.