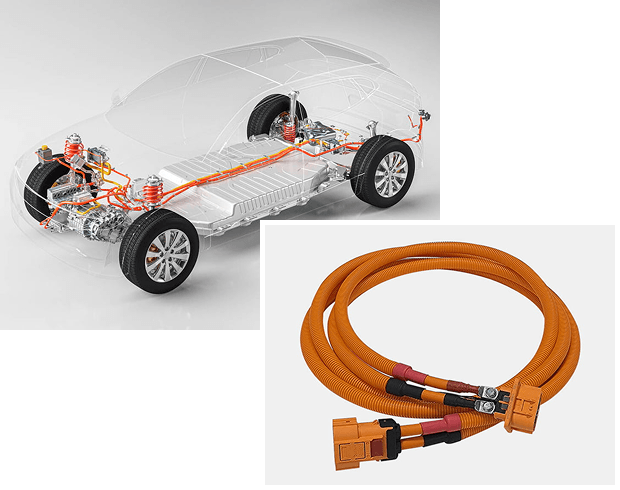

Product Introduction

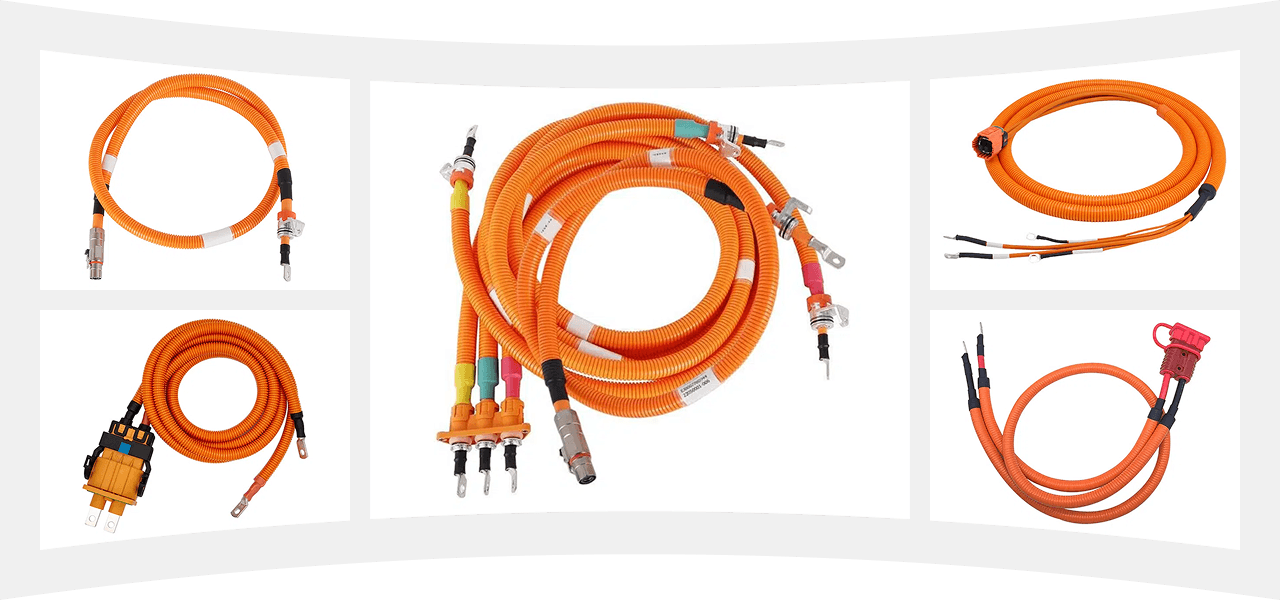

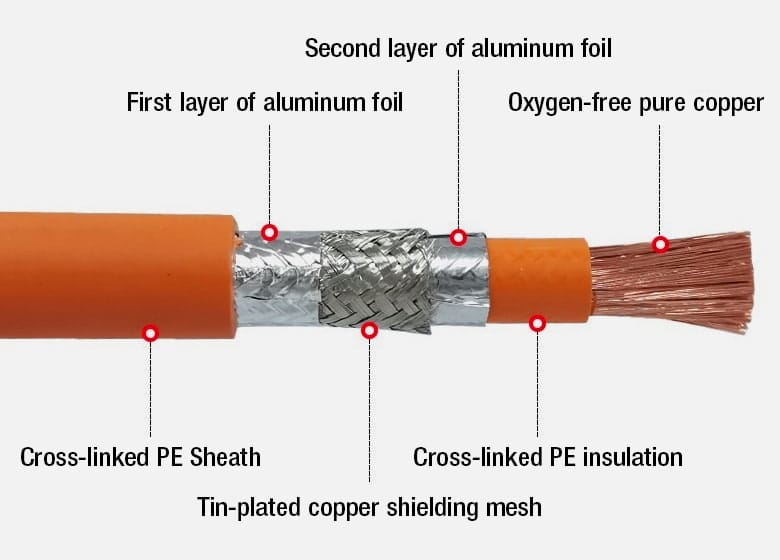

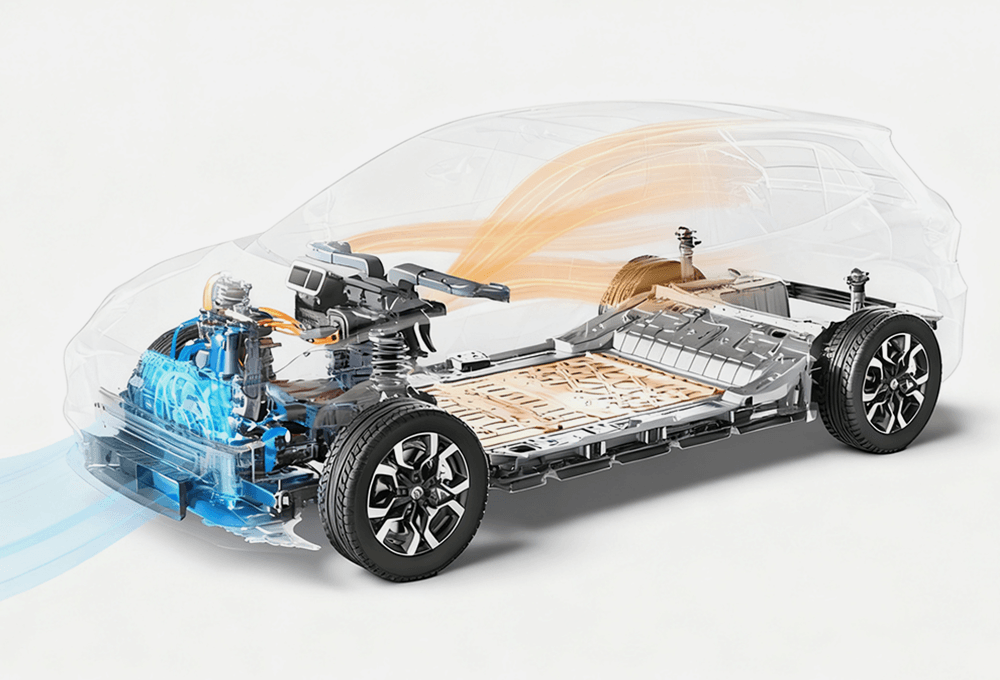

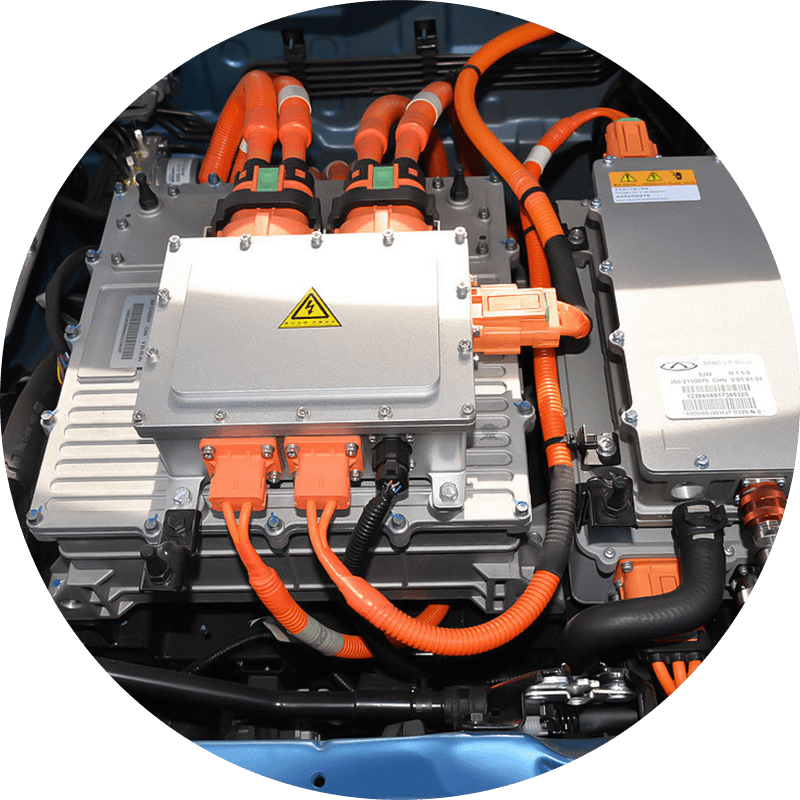

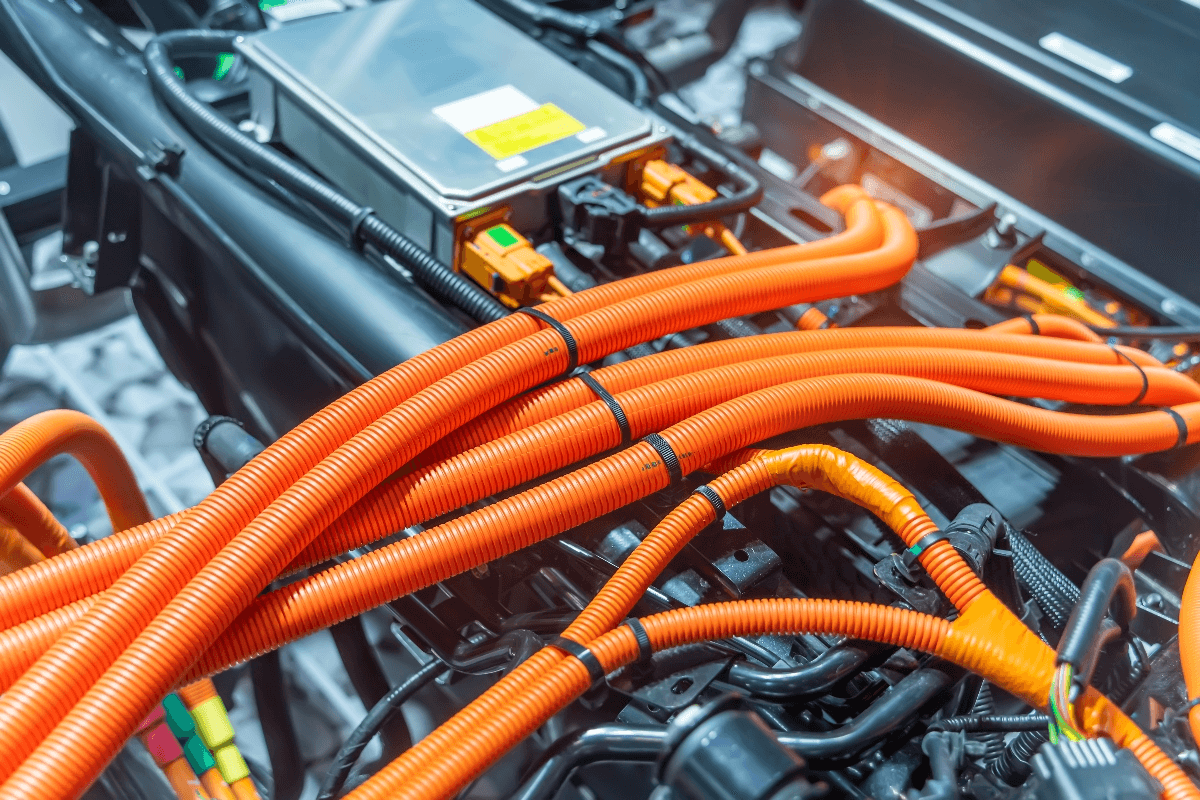

Our high-voltage wire harnesses are especially designed to transfer the most accurate type of signals and the energy level. The core of the harness is built with the most durable and flexible copper type to keep the quality high. The harnesses have the most durable and flexible type of outshell to keep the machine secure. We carefully sealed every harness, stars and ends to resist dirt and other harmful elements. To keep the control system secure and working perfectly, these harnesses are covered with flexible and hard materials. These harnesses can also resist the quick shock and high electricity at the same time. The harnesses are carefully tested before shipping them to you. The cables and the materials are perfectly added to the harness for longevity.