Product Introduction

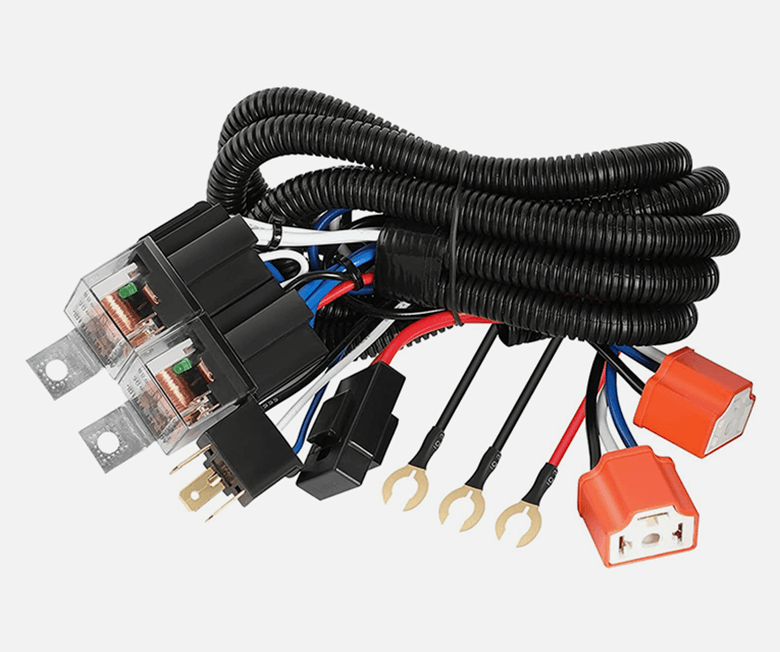

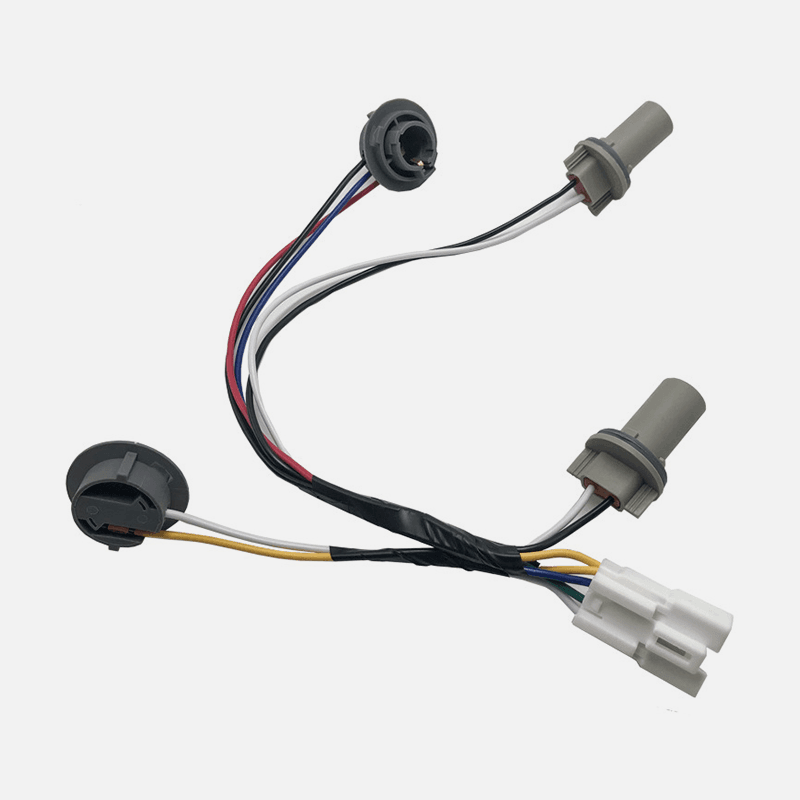

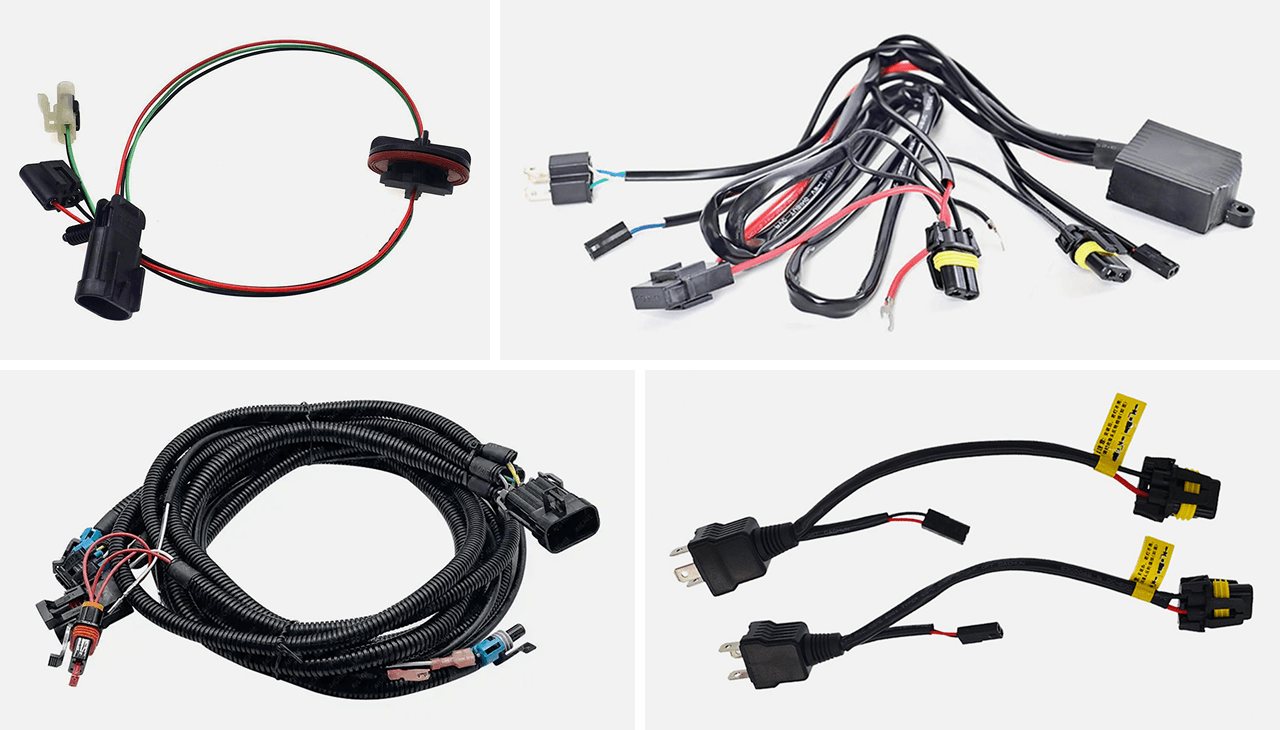

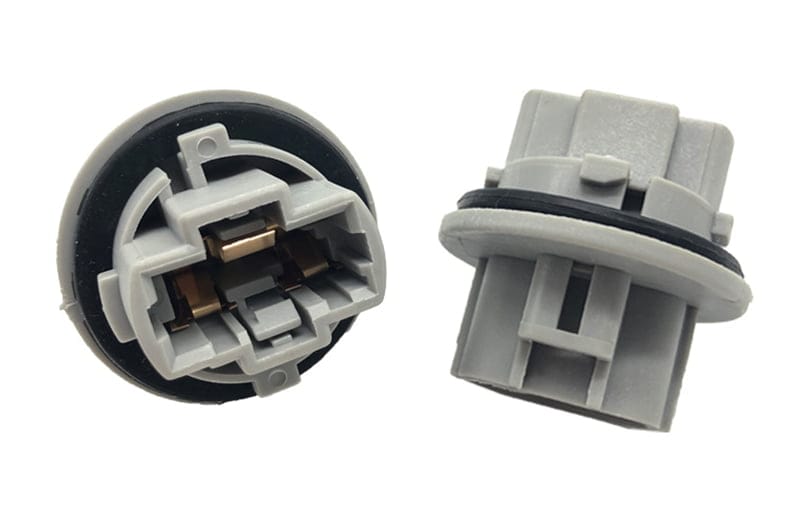

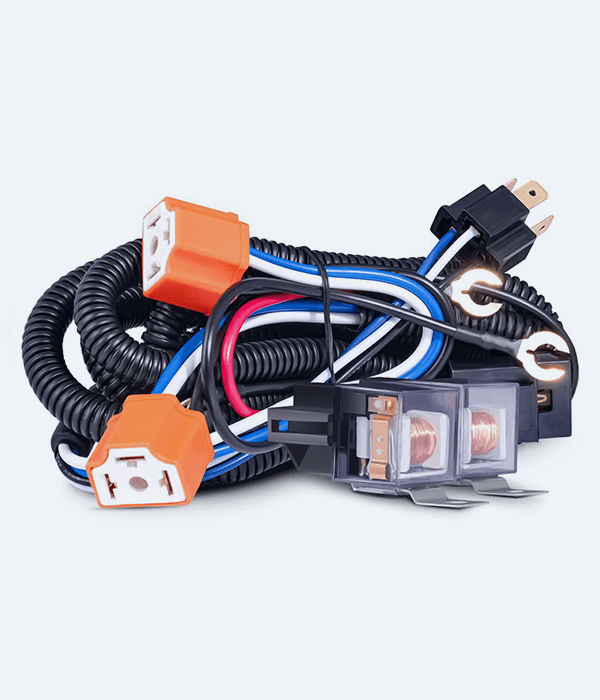

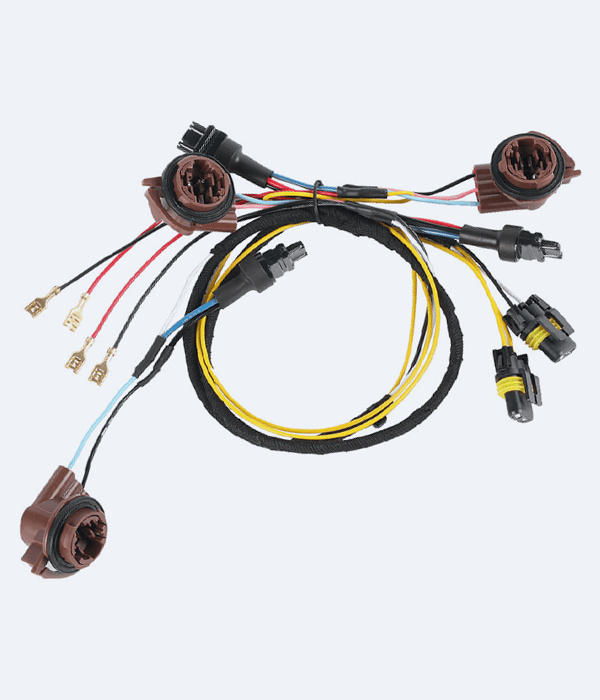

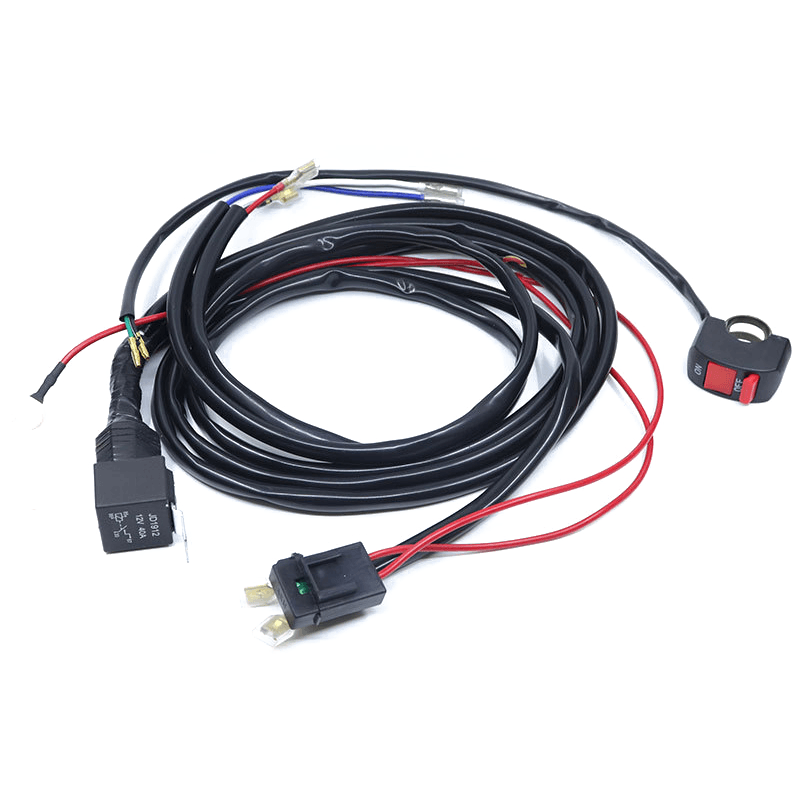

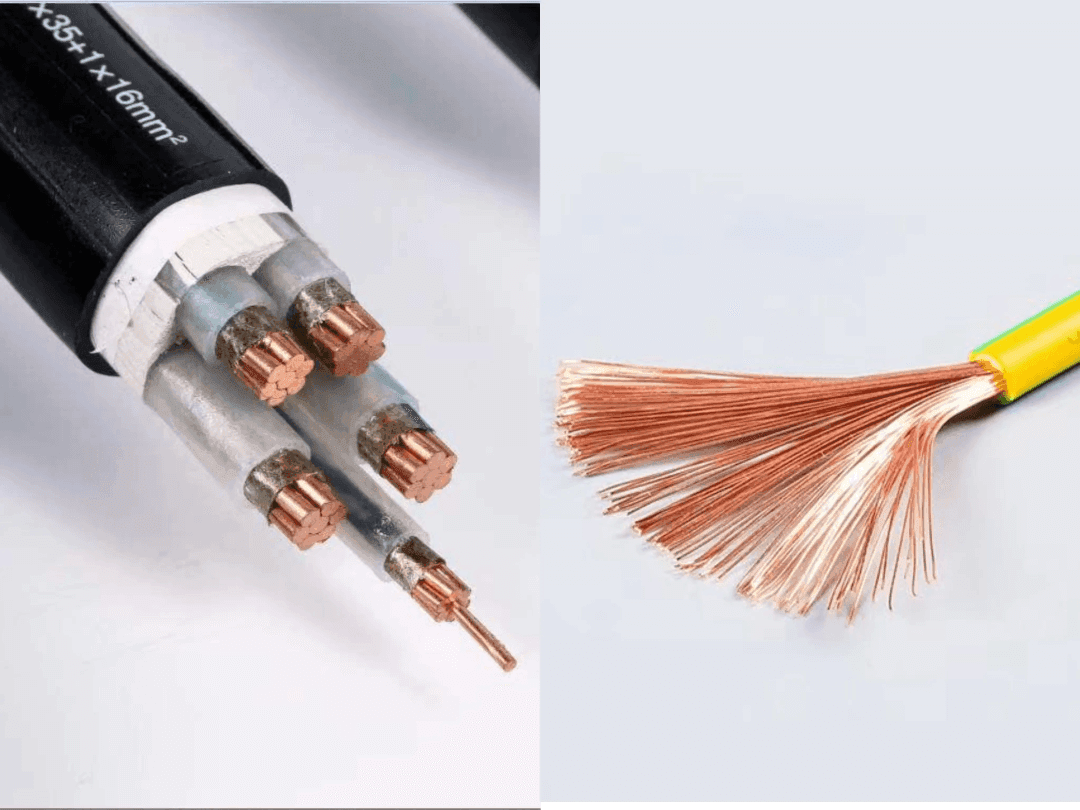

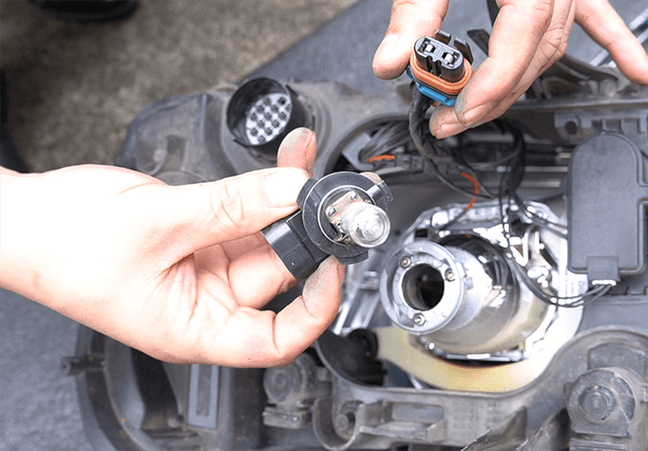

The auto light wire harness kit is made for easy use by all drivers. It provides safe power from the car's battery or fuse box to all your lights in a single, clean way. It works with headlights, fog lights, brake lights, turn lights, and side lamps. The sockets are correctly placed with the cables to keep the bulb in the proper place. The copper wires stop power from dropping, so the lights glow at full strength every time. This vehicle's auto light wire harness can fit many kinds of cars. These harnesses have the correct wire density to pass the voltages smoothly. This means the kit can work even when you use multiple lamps simultaneously, and it will not fail or overheat. QL-Custom's automotive lighting wiring kit is designed to be plug-and-play, allowing for easy connection and use. This ends the guesswork and hard jobs of wiring.