Product Introduction

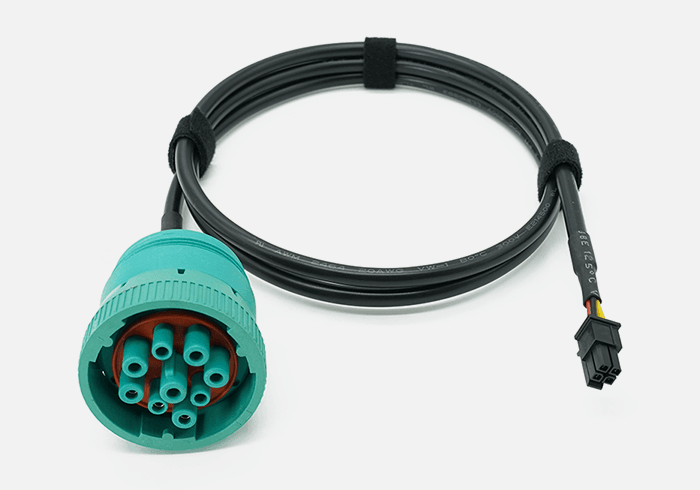

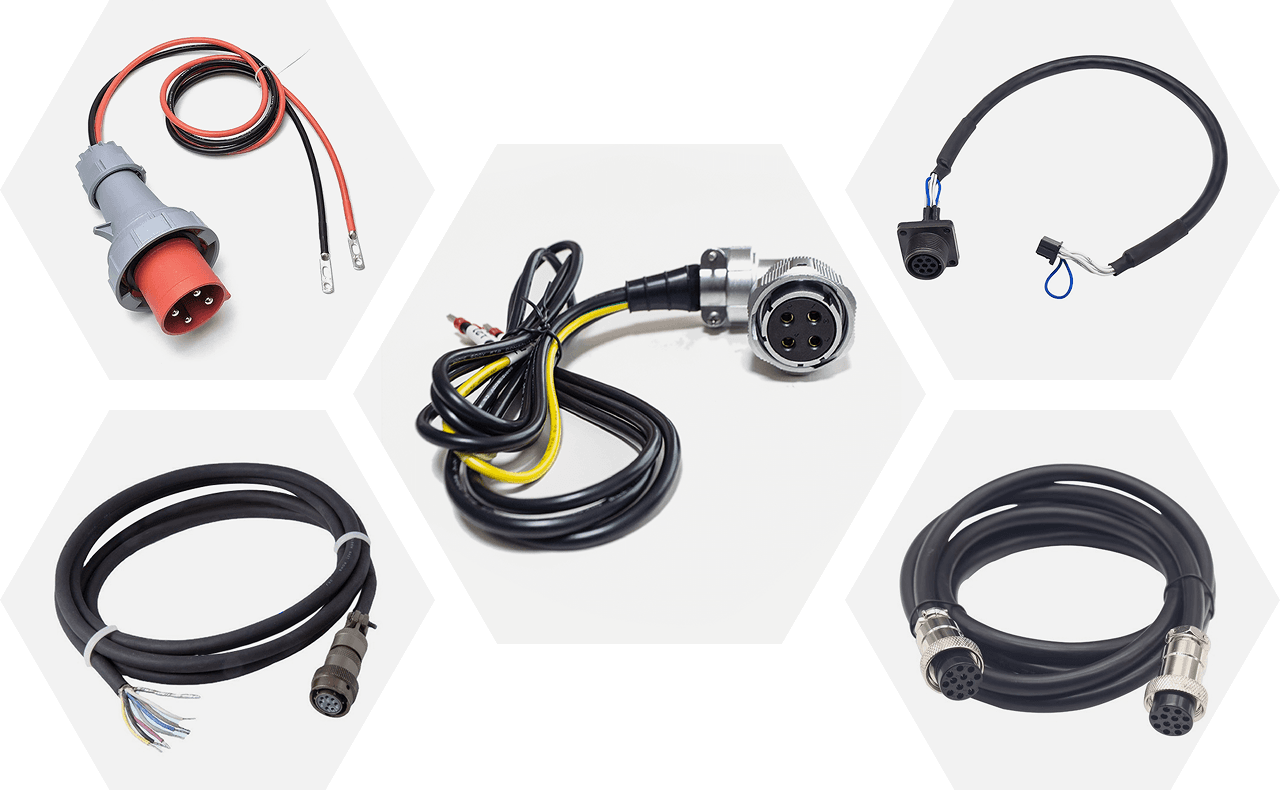

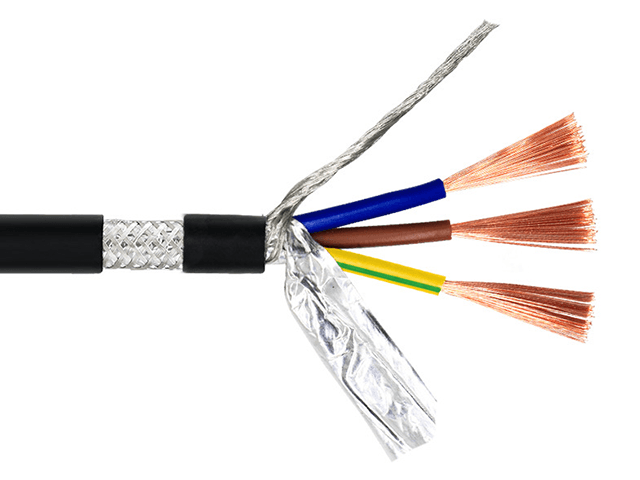

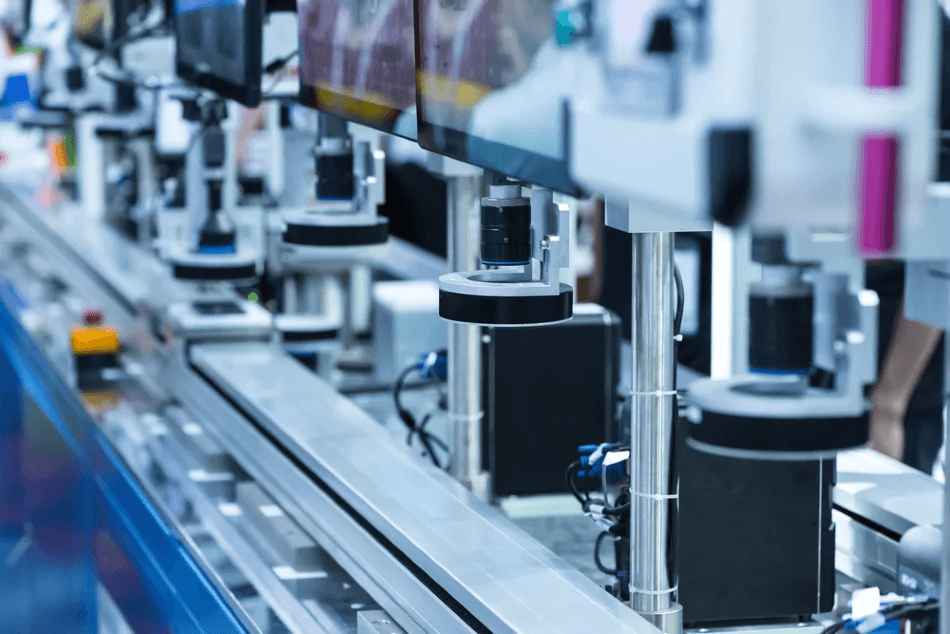

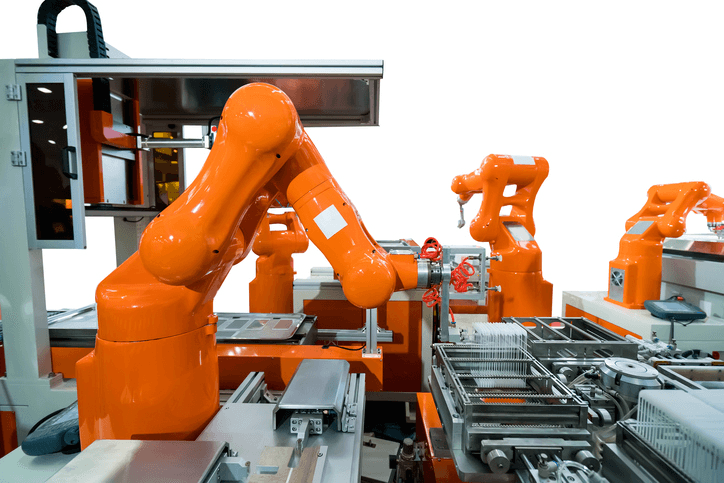

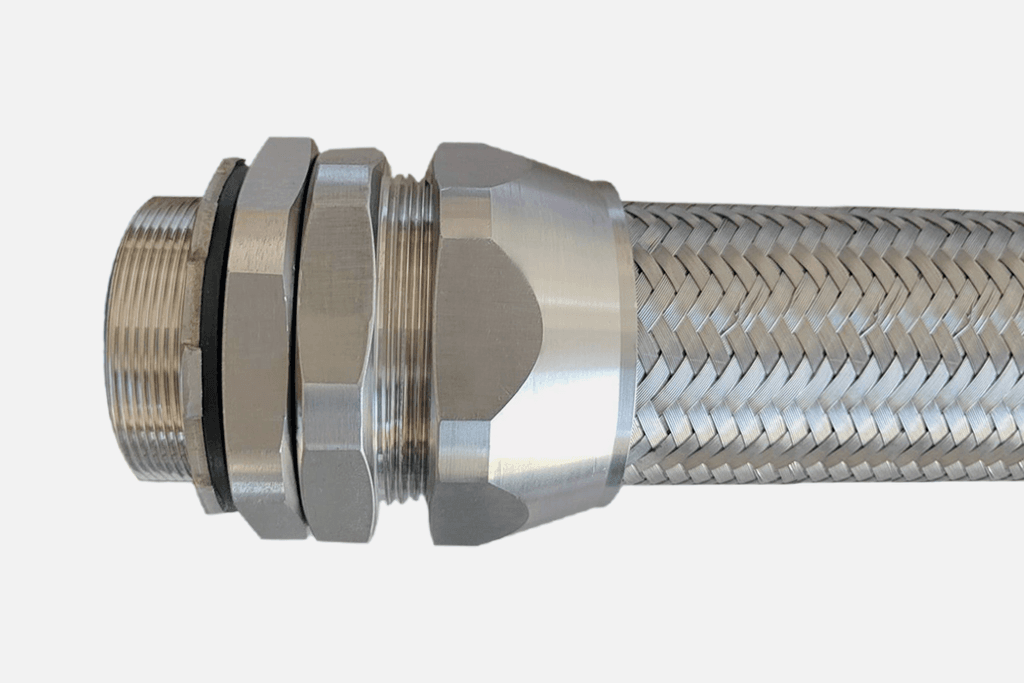

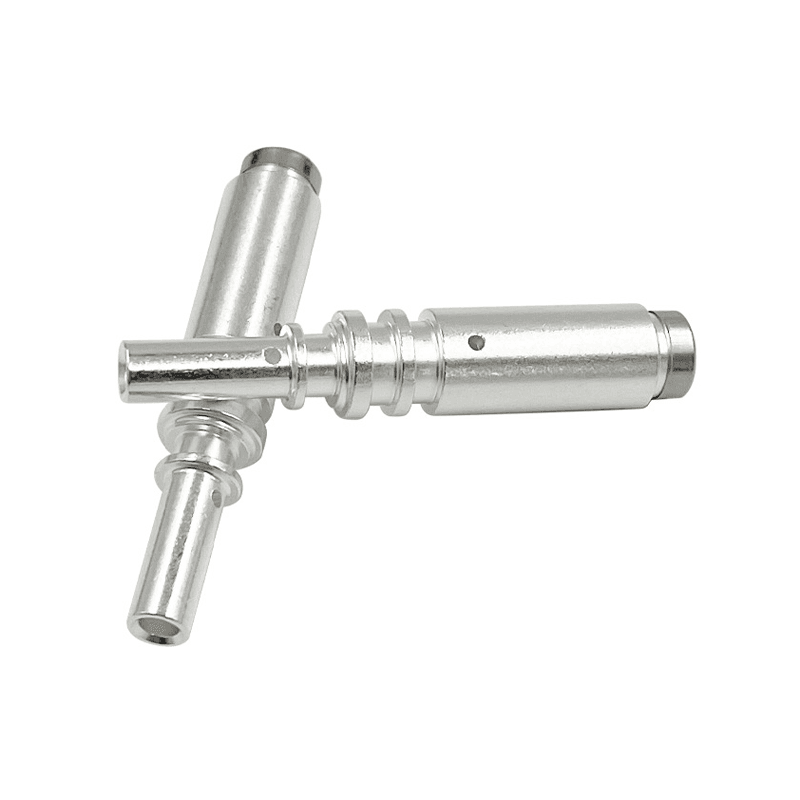

A circular connector cable assembly has a round connector already fixed on it. A common one is the M12. It has a strong shell outside, a block inside to hold pins, and pins that carry power or signals. The shell twists and locks onto another piece, and a rubber O-ring stops water from getting inside. In Figure 1, you see a female connector with many pins. The most used sizes are M5, M8, and M12. The M12 is the world standard used in machines and sensors. Each pin has a mark or color, so wiring is easy. Work is faster, safer, and cleaner when the connector already comes with a cable. You do not need to wire by hand. Our assemblies use molded ends, copper or silver pins, and tested parts. And we always use the tested and certified parts.