Product Introduction

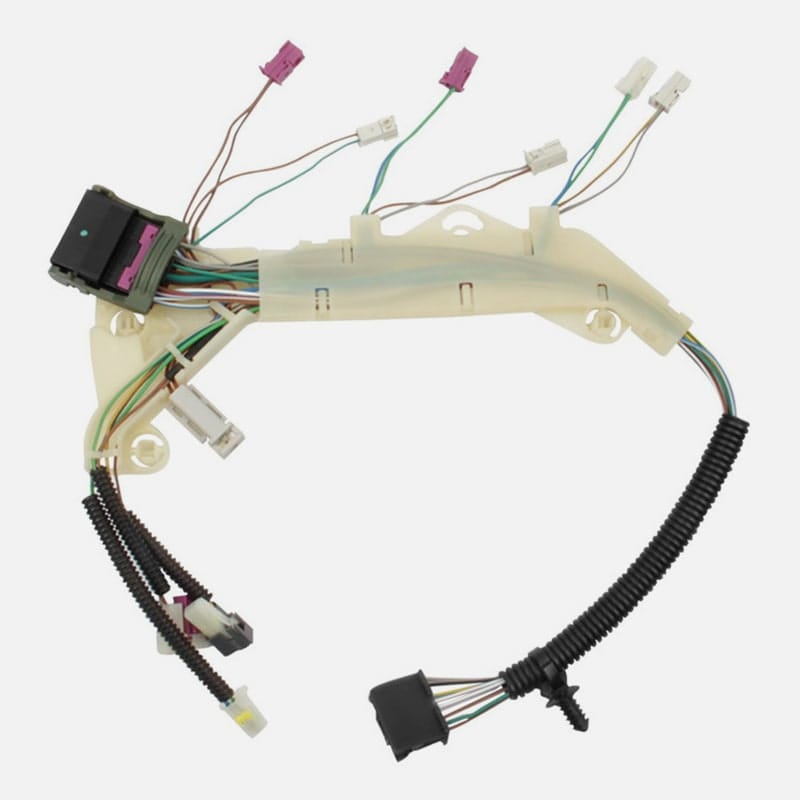

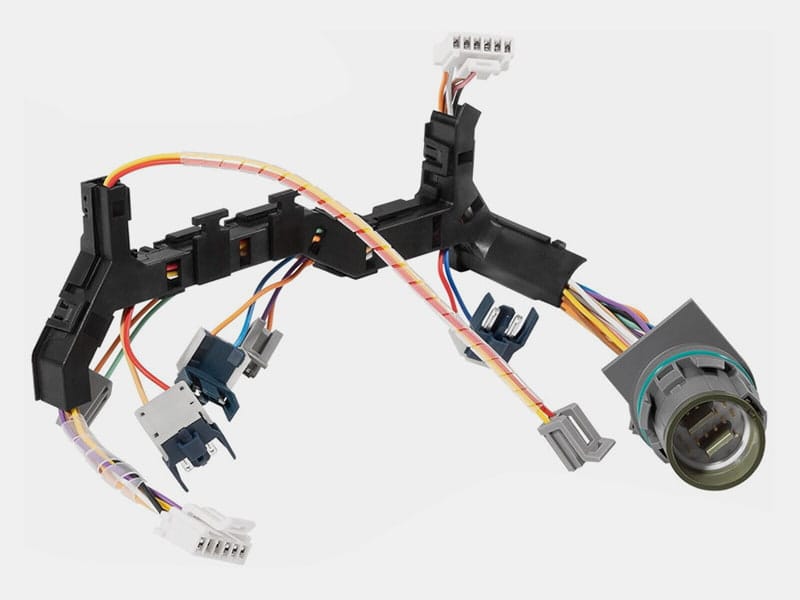

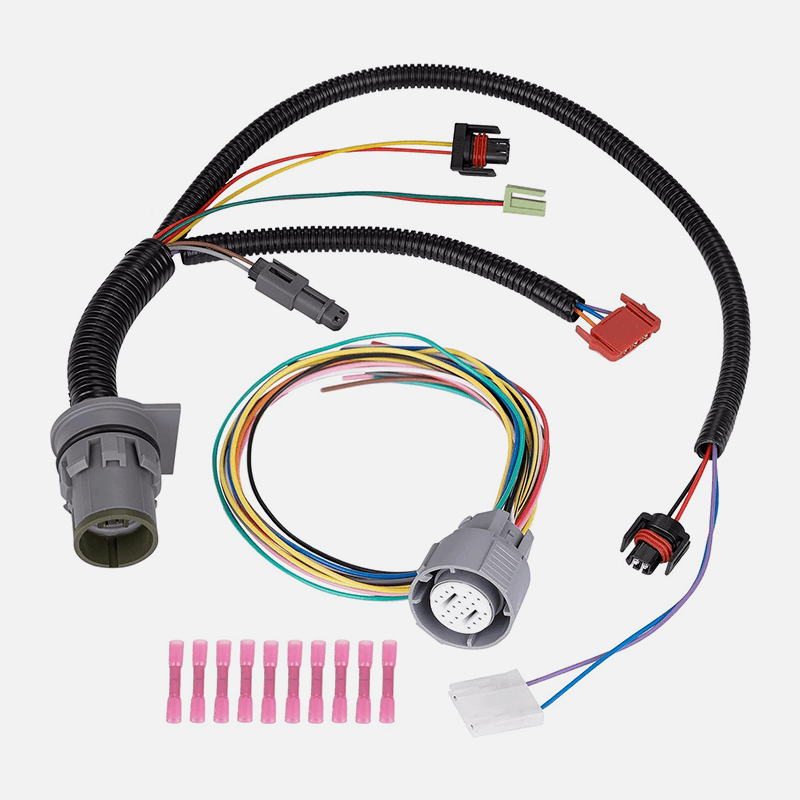

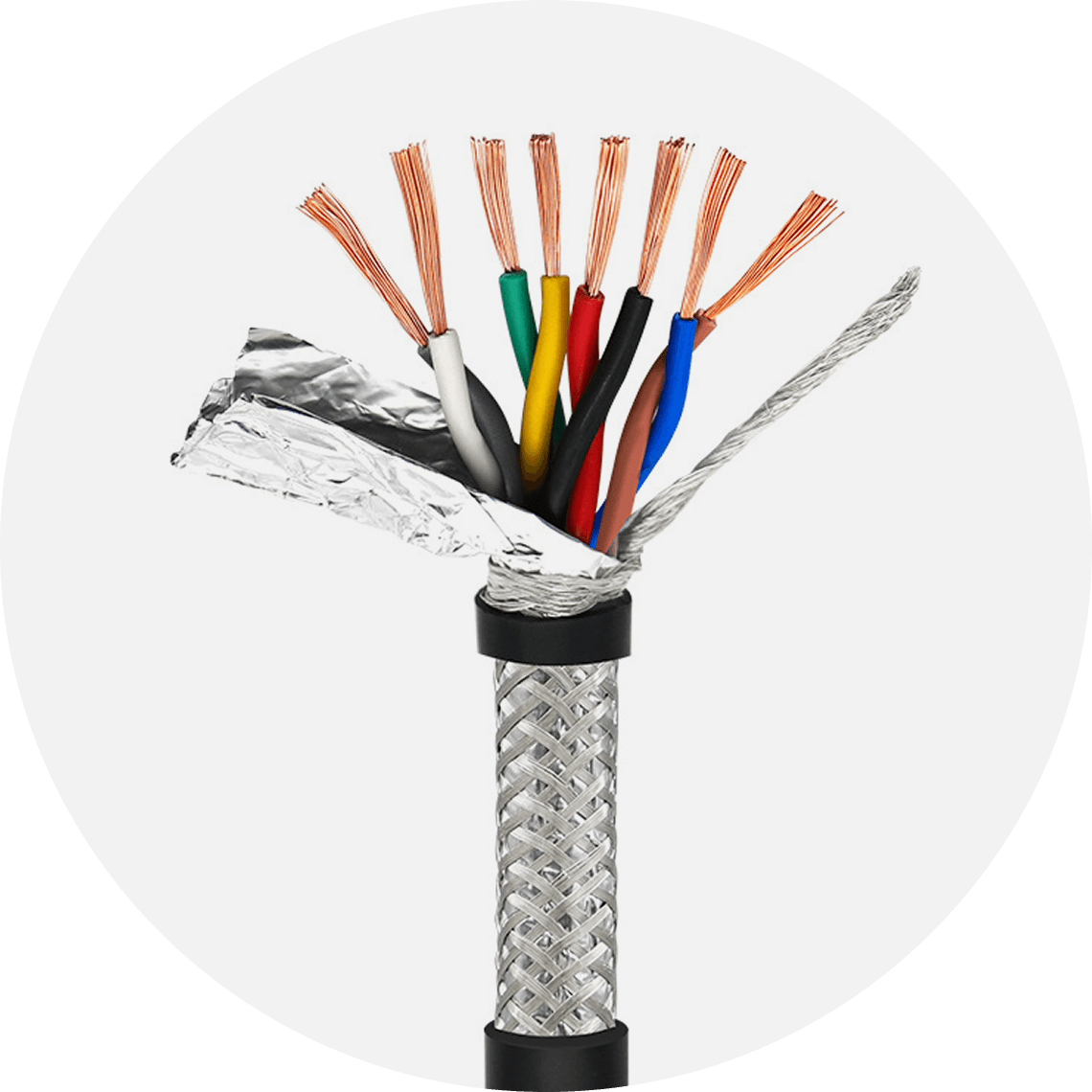

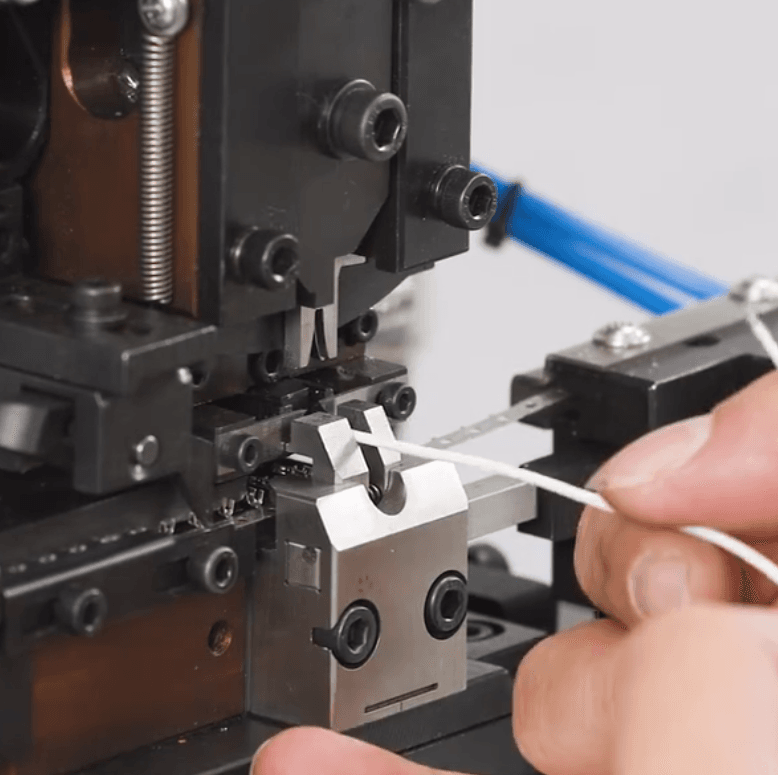

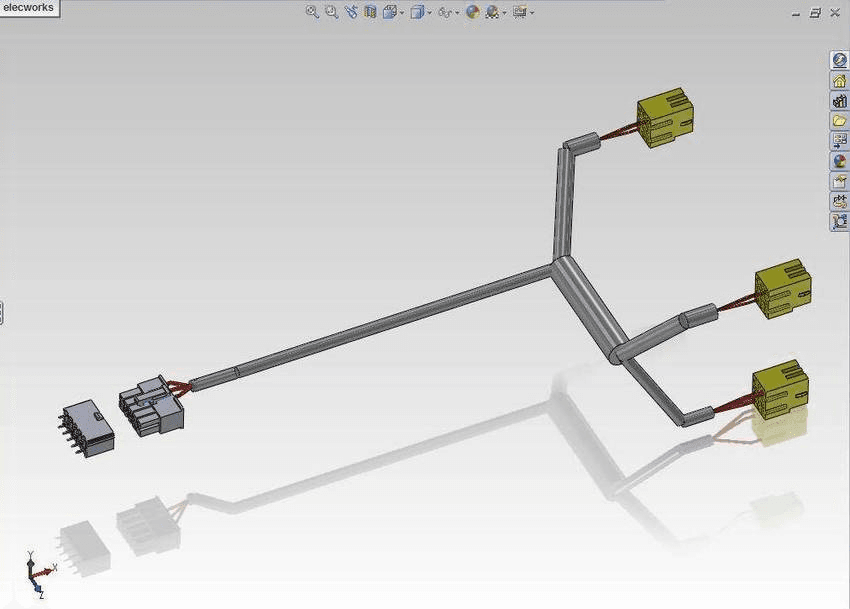

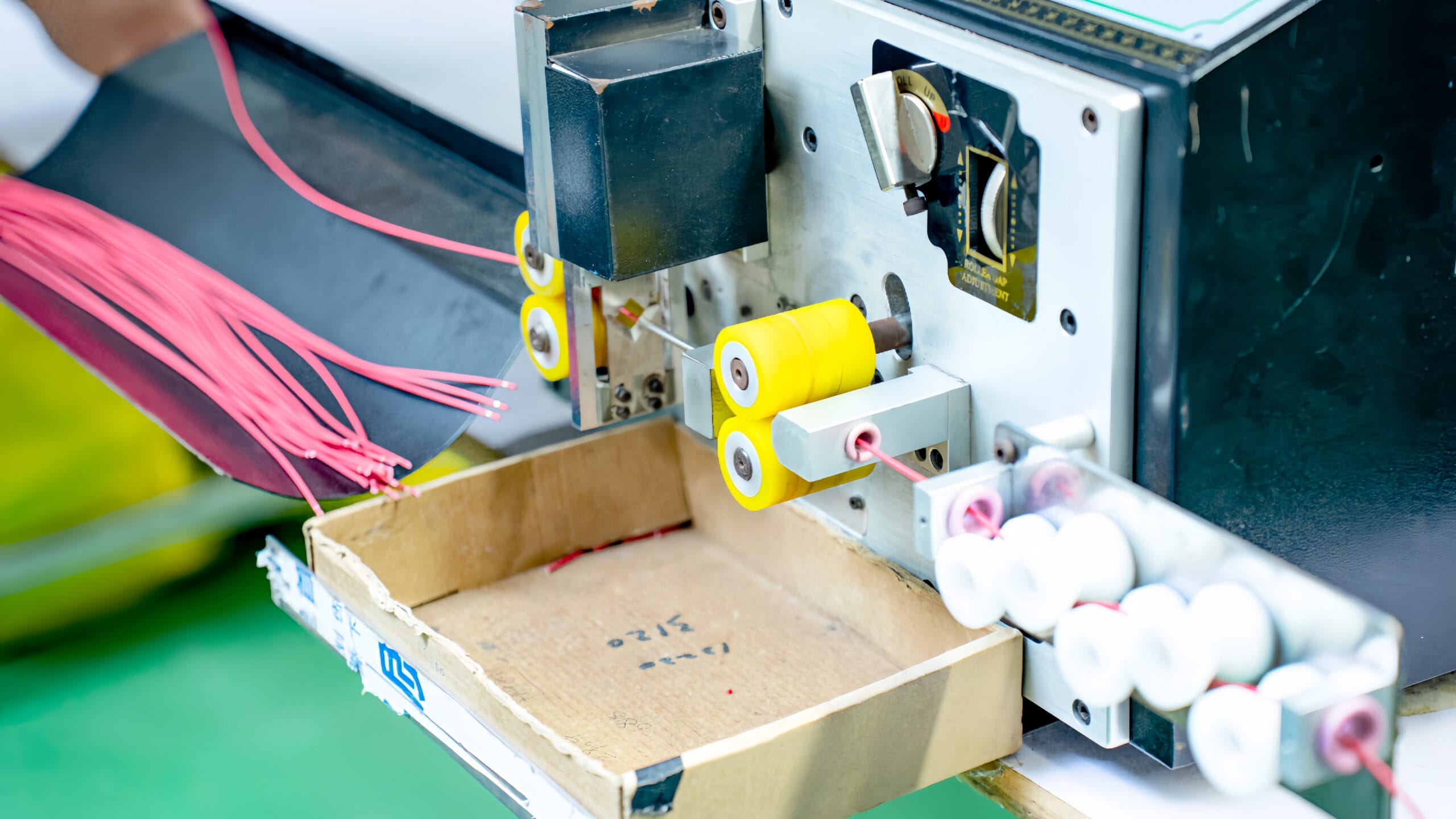

Our rust-proof transmission wire harness is made for extended, worry-free use. It fits nicely in cars, trucks, and many machines. We use strong plastics and coated metals to ensure the harness does not break or rust prematurely. This means fewer stops, fewer fixes, and steadier work. We also use 100% copper wire, which helps send clear signals and strong power. We cover and wrap each part of the harness to keep it safe. The shaped parts near the connectors help block water, dirt, and dust from entering. Shrink tubes and cloth wraps keep wires from rubbing or breaking. We test each harness under heat, shaking, and salt to ensure it remains strong in real-world use. We also add clear labels to help workers install and repair it straightforwardly.