Product Introduction

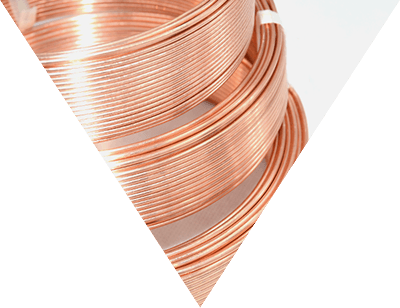

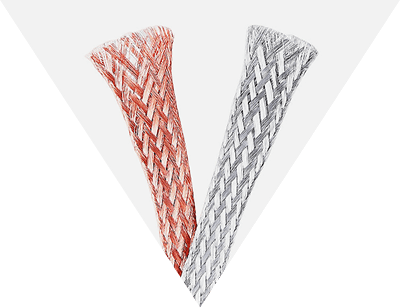

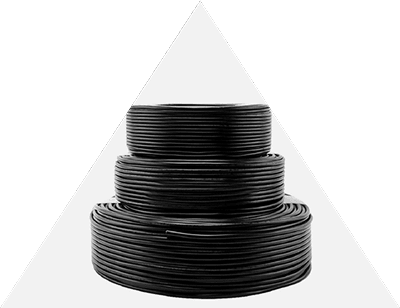

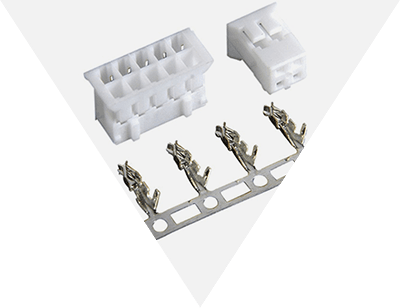

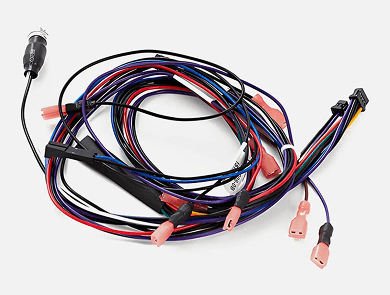

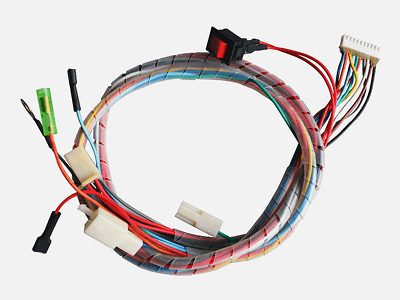

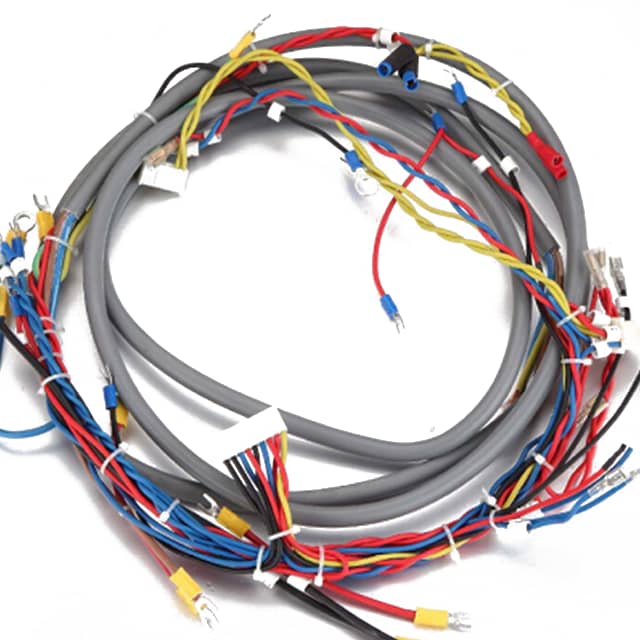

We make control wire harness assemblies for many machines, from small tools to large factory systems. These harnesses link important parts like sensors, motors, switches, and controllers to work together. We can create a control panel wire harness, a PLC control wire harness, or a custom harness built just for you. Our industrial control wire harness is perfect for large plants. In contrast, our machine control wire harness works with heavy-duty tools and machines. Every wire is measured carefully, cut to the exact length, crimped tight, and labeled clearly so installation is quick and straightforward. The outside layer protects the cables from heat, oil, dirt, and water. We thoroughly test every harness before it leaves our factory. We can make small orders or unique custom designs. Our goal is to make wiring safe, easy, and built to last.