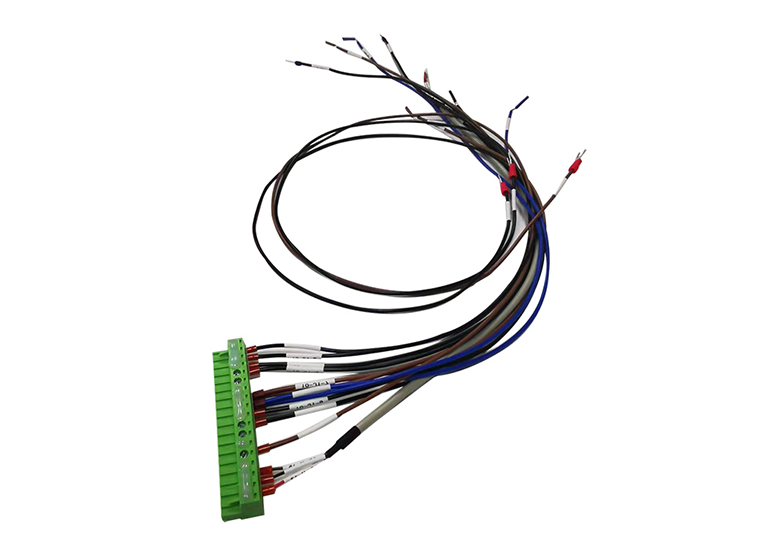

What is Industrial Wire Harness and how does it work?

An industrial wire harness is a smart way to keep many wires together in one neat bundle. These wires help carry power or signals from one part of a machine to another. Instead of letting wires hang all over the place, a wire harness ties them tightly using tape, sleeves, or plastic covers. This makes machines safer, cleaner, and easier to fix. You can find industrial wire harnesses in cars, factories, robots, and many big machines that work every day.

So, how does it work? The harness acts like a road map for electricity. It connects the power supply to motors, switches, lights, and sensors. When the machine starts, electricity flows through the wires to make each part work. Without the harness, the wires could get twisted, cut, or even cause a fire. But with a harness, everything stays in place and runs smoothly.