Aerospace cable assembly

Aerospace cable assembly bundles multiple wires into one rugged harness. These assemblies carry power and data in aircraft, satellites, and defense systems. Each harness is high-quality.

Aerospace cable assembly bundles multiple wires into one rugged harness. These assemblies carry power and data in aircraft, satellites, and defense systems. Each harness is high-quality.

Aerospace cable assembly is a specialized group of wires used in airplanes and spacecraft. These wire groups are also referred to as harnesses. A harness combines multiple cables into a single, organized unit. It carries power, signals, and data to different parts of an aircraft or satellite. These assemblies utilize strong materials designed for aerospace applications. They can withstand high heights, extreme temperatures, and vigorous shaking. Many assemblies also have metal shields and tough outer covers. These features help stop signal noise and protect the wires from damage. Manufacturers follow strict rules called MIL-SPEC and ISO standards. Every aerospace cable assembly is tested before it can be used for flight. We utilize high-quality parts, including MIL-DTL-38999 connectors. This careful process ensures that each harness works safely in extremely harsh conditions.

Connector size is essential in aerospace systems. Size affects weight, space, and the number of wires a connector can accommodate. Aerospace connectors are available in standard sizes, referred to as shell sizes. Small connectors are lighter and hold fewer pins. Larger connectors can hold many pins and carry more power. For example, MIL-DTL-38999 connectors are available in sizes ranging from 8 to 35. Size 8 is small, while size 35 is much larger. Engineers often opt for small connectors when working in tight spaces. They prefer larger ones when many wires are needed. The goal is to strike a balance between space, weight, and performance. High-density connectors can accommodate more than 100 signal pins while remaining compact.

Airplanes and spacecraft face very harsh conditions. Connectors must survive shaking, heat, cold, moisture, and chemicals. Mil-Spec connectors are designed to withstand these challenges. For example, MIL-DTL-38999 connectors have strong metal shells. These shells protect the contacts inside from shock and vibration. They are made from materials like aluminum or stainless steel that resist rust. Seals and gaskets prevent water, dust, and dirt from entering. Strong locking systems stop the connector from coming loose. Due to these features, the connector remains safe and reliable during flight. This is why aerospace connectors must comply with strict environmental regulations.

Certified connectors are crucial for safety. Certification means a connector has passed rigorous tests. These tests evaluate vibration, shock, heat, fire, and salt spray resistance. MIL-SPEC connectors come with proof that they meet industry standards. This proof helps engineers trust the parts they use. Certified parts also allow full tracking of materials and quality. For example, MIL-DTL-38999 connectors meet the tests outlined in MIL-STD-1344 and MIL-STD-202. Using certified connectors helps prevent failures. It also builds trust with regulators and customers. Certified parts help keep aircraft and spacecraft safe.

Every aircraft and space system is different. As a result, many Aerospace cable assembly wires are custom-made. Custom harnesses are designed with the right length, wire size, and connector type. Special features can also be added. These may include shielding to block signal noise or filters to clean signals. Some aerospace cable assemblies use PTFE materials for fire resistance. Others use special designs to fit tight or unusual spaces. Extra support parts help protect the cable and connector. Custom designs allow engineers to meet exact needs. This makes the system safer and more reliable.

SR means strain relief. Strain relief protects the cable where it meets the connector. This area is a shared place for damage. Strain relief stops pulling and bending forces from hurting the wires inside. In aircraft, connectors often use molded or clamped strain relief boots. These boots spread stress along the cable jacket. This helps protect solder joints and insulation. Strain relief also keeps the connector steady during vibration. Many circular connectors use rear clamps or threaded backshells. These features make the aerospace cable assembly last longer. Strain relief helps keep wires safe even when the aircraft moves or shakes.

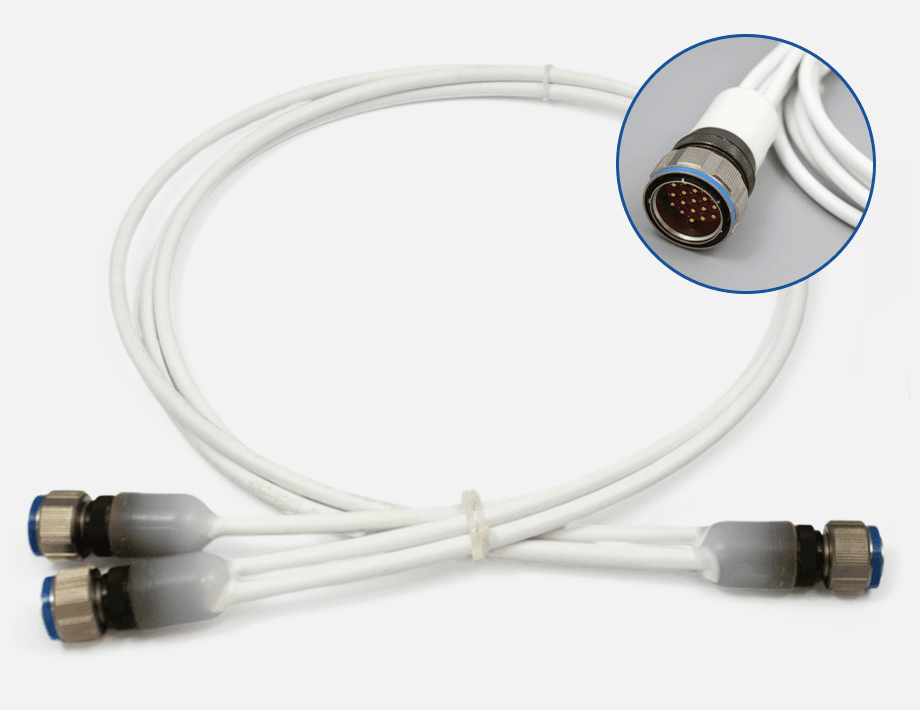

GX16 connectors are round connectors with a diameter of 16 mm. They are sometimes called aviation plugs. These connectors usually have 2 to 12 pins. They have metal bodies and screw together securely. GX16 connectors are often used for low-power or signal connections. They may be used in instruments or control panels. These connectors are strong and easy to handle. While they are not MIL-SPEC, they still work well in moderate conditions. GX16 connectors are often used in conjunction with mil-spec connectors in custom aerospace cable assemblies.

MIL-DTL-38999 connectors are widely used in aerospace systems. They are round connectors designed for use in harsh conditions. They come in Series I, Series II, and Series III. Series I and II use a push-and-twist locking method. Series III utilizes a fast-threaded lock. All series can withstand extremely hot and extremely cold temperatures. Series I connectors are strong and resist water and vibration. Series II connectors are thinner and lighter in design. They are good when space is limited. Series III connectors lock quickly with a short turn. These connectors can carry high power or many signals. Because they meet military standards, they are trusted for use in flight.

Space power connectors are used in satellites and spacecraft. They carry high power and high voltage. These connectors send power to batteries, engines, and solar systems. They are made from special materials that work in space. These materials do not release gases in a vacuum. Space power connectors are approved by space agencies like NASA or ESA. They often use gold-plated contacts to prevent corrosion. They must survive strong vibration during launch and radiation in space. Many space power connectors also carry signal lines. These connectors help ensure that power flows safely during critical missions.

Aerospace cable harnesses use strong and safe materials. These materials enable wires to function effectively in airplanes, helicopters, and spacecraft. The metal wires inside are usually made from pure copper or silver-plated copper. These metals carry electricity very well. The wire coating, known as insulation, is made from specialized plastics such as PTFE, PEEK, or silicone rubber. These plastics can handle very high heat and do not burn efficiently. The outer jackets and braided layers add strength and protect the wires from damage. Many parts are chosen because they are lightweight, fire-resistant, and long-lasting. Some cables utilize a silver coating to enhance performance. Insulation may be thin, but it is powerful.

Silver-plated copper wires are commonly used in aerospace systems. Copper carries electricity well, and silver helps protect it. The thin silver layer reduces resistance, allowing the wire to function longer. It also prevents rust and damage at high altitudes and high temperatures. Silver works well with fast signals, which is helpful for data and radio lines. Due to this, these wires are commonly used in avionics and satellite systems. They are light but strong. They can carry high power without losing quality. Silver-plated copper helps cables remain reliable in harsh conditions.

PEEK is a strong plastic used in aerospace wiring. It does not contain harmful gases and burns slowly. This makes it safe for aircraft and spacecraft. PEEK stays strong even at very high temperatures, up to about 260°C. It also resists radiation, chemicals, and wear and tear. Due to this, PEEK is often used in areas near engines or in high-temperature environments. It also protects wires in space and military vehicles. PEEK does not crack or weaken easily. It keeps cables safe in harsh places. That is why aerospace engineers trust PEEK materials.

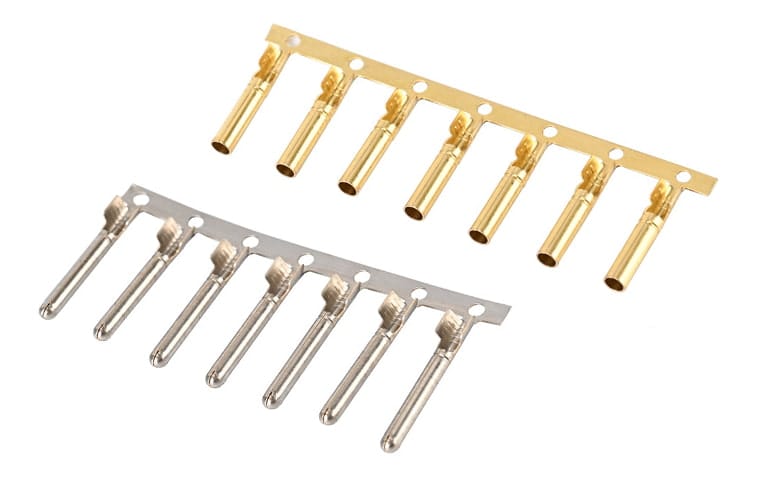

Connector contacts must stay clean and strong. Aerospace connectors often use nickel and gold plating. Nickel makes the contact hard and helps it keep its shape. Gold is added on top because it does not rust or corrode. Gold maintains a smooth and reliable electrical connection. It also works well after many plug-and-unplug cycles. Gold can handle high heat without damage. The nickel layer protects the base metal. The gold layer ensures good signal flow. Together, they meet strict aerospace rules. This plating helps ensure that connectors work safely for an extended period.

People often use extra covers on aerospace cable harnesses for safety. Examples include molded jackets, braided sleeves, and heat-shrink tubes. Fiberglass or aramid braided coverings make things last longer and resist heat better. Some covers have silicone or PTFE coatings. These materials can handle very high temperatures. Fire-resistant jackets can stop fires from spreading. Specialized shielding coverings can keep electrical noise from getting through. This stops communications from being messed up. These layers add extra protection against wear, vibration, and friction. Each cover gives the harness more protection inside the plane.

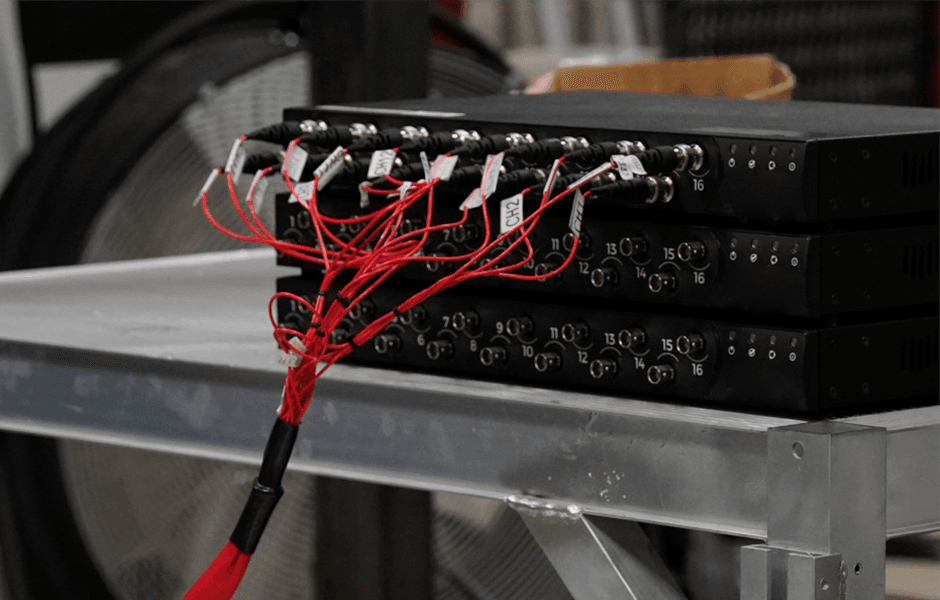

This kind of harness is standard for planes and helicopters. These connect the systems in the cockpit, the engines, and the cabin. They can handle high temperatures, electrical noise, and shaking. Every part meets the rules for keeping planes safe

Military aircraft and equipment use cable assemblies that are very strong. These lines are important for radios, the power grid, and radar. They can handle dirt, pressure, and bad weather. Everything meets the military's standards.

Drones use small, strong wire harnesses. These wires don't mind vibration or sudden movement. While in flight, they safely move data and power. Custom designs for drones can make them work better and last longer.

Space harnesses are used by launch vehicles and spacecraft. They must be able to handle violent shaking when they are launched. They can even work in places where there is no air. These connections make sure that systems in orbit work correctly by following the rules set by space agencies.

These cords send signals and data very quickly. They are used by cameras, radar, and navigation systems. Data and fiber-optic connections make it possible for communications to be sent without damage. They are important for both safety and control.

For testing, airplanes and space systems use special cables. They connect test instruments and ground stations. With these harnesses, you can safely look at and fix anything. They are made to be used accurately and many times.

We test all of the cables and connections to make sure they meet aviation standards.

Next, we'll carefully cut and attach the wires using the right methods. Sealing

Sealing off important areas helps protect them from stress and weather.

Wires are wrapped up and put together to keep them safe and organized.

Every cable is tested electrically to make sure that signals are sent and received correctly and reliably.

Testing in very hot and cold weather, high humidity, vibration, and shock is all part of the environmental testing process.

Fire testing is done to make sure that the harnesses won't catch fire or burn too quickly.

The last step of the inspection process is to check the quality and make reports for approval.

Our aerospace cable assembly boasts silver-plated copper conductors for low signal loss, PTFE/polyimide insulation resistant to -65°C to 260°C, and dual-layer EMI shielding (foil + 95% braid coverage) to combat electromagnetic interference. Compliant with AS9100D and MIL-DTL standards, it integrates aramid braiding for abrasion resistance and lightweight construction, optimizing aircraft fuel efficiency. Fully customizable in length, pinout, and shielding, it undergoes rigorous vibration, radiation, and thermal cycling tests. Ideal for avionics, defense systems, and satellites, it delivers uncompromised reliability in harsh aerospace conditions while meeting strict weight and performance requirements.

The avionics systems need to work all the time while the plane is in the air and vibrating. This means that Aerospace cable assembly cables need to be strong. We test our cable assemblies to make sure they can handle constant vibration. We use strong ties and braided insulation to keep the cables safe. The MIL-DTL-38999 connection shells are great because they keep shock, vibration, and water from getting in. We also add slack loops to the wires so they can bend without breaking. Flexible solder joints and strain relief parts keep the wires from getting damaged. The cables have special coatings and a lot of insulation to keep the connections safe. There is no way for any of the connectors to come loose because they are all securely fastened. The way the harness is made means it could last for several hours of flying before it breaks.

We needed a reliable cable harness for our UAV project. QL-Custom delivered high-quality assemblies on a tight schedule. The connectors and build quality were excellent.

The QL team was invaluable and responded quickly. They helped us design a custom harness for our radar system. The cables met all our requirements.

Great service and strong products. We used MIL-DTL-38999 connectors for a satellite project. Everything arrived on time and passed inspection without issue.

Fast quotes and fast delivery. The power cables work well in our cockpit systems. Very reliable quality.

Clear communication and solid results. QL helped improve our design and delivered exactly what we needed for our drone project.

QL-Custom is our trusted supplier for aerospace cable assembly cables. Their products are certified, well-built, and dependable.

Choosing the right manufacturer is very important. QL-Custom Technology Ltd. is a reliable partner for aerospace cable assembly. We have been in business for more than 20 years and have earned the ISO 9001:2015 certification. Our employees are very skilled and knowledgeable. We are proud of the great help and high-quality work we do. We can usually give you a price within four hours, and our service is quick. We make and test all of our cable assemblies in-house. People all over the world know us for making deliveries that are on time, reliable, and cheap. Don't hesitate to get in touch with QL-Custom if you need help putting together aircraft cables.