Product Introduction

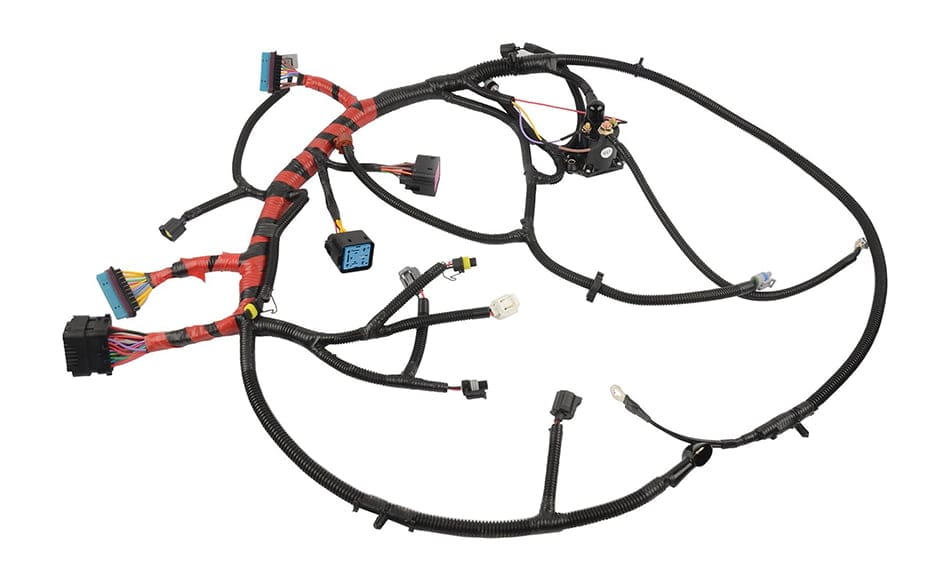

Inside our engine wire harness, the wires are carefully managed and attached. The cover of the harness is built with the best quality materials to prevent bad situations. The harness has many layers that keep the inner materials safe from the other materials. The connectors are designed to be accurately attached to the other parts. The easy-to-use setup makes the harness easy to use. The harnesses are tested carefully to ensure the top-grade quality and the best service for your machinery needs. All the parts in the harness are carefully attached for long-lasting performance. With our harness, your vehicle engine gets the most exact power supply and the exact signals without any issues. The harnesses we offer you are of the best quality. First, we carefully listen to your recommendations and then we plan the whole process then we smartly start working on your project to offer you the best harnesses.