Low pressure molding materials in cable & wire Assembly

Low pressure molding materials are a special way to keep wires safe. It uses soft plastic that is warmed up. This plastic covers the wire parts and fills in all the gaps. When it cools, it becomes a strong shell. This shell keeps out water, dirt, dust, and anything that could hurt the wires. It also helps hold everything in place. That stops wires from moving too much or breaking. The final look is clean and neat. This method is also quick and does not cost much, which makes it a great choice. Why Low Pressure Molding Materials Is Used Low pressure molding is a simple and safe way to protect wires and small parts. It works by using a soft plastic that melts with low heat. This plastic is poured or pushed into a mold that shapes it around the wire or part. Once the plastic cools, it turns hard and strong. The hardcover keeps water, dirt, and oil from getting in. This helps stop damage. It is perfect for protecting electronics and small things that can break easily. Since the heat and pressure are low, it is safe for tiny parts like plugs and sensors. This way of covering things is fast, neat, and helpful for many jobs. How Does Low Pressure Injection Molding Work Let’s look at the steps. First, a mould is made to match the shape of the item that needs covering. The mould is often made from light metal. Then, the part, like a wire or small board, is placed inside the mold. A low pressure injection molding machine melts soft plastic called hotmelt. This melted plastic is slowly pushed into the mold. It wraps around the part gently. This does not harm the part inside. After a short time, the plastic...

Read More »Why using custom made cables in machinery

Cables are essential parts of machines and electronics. They help move power from one place to another. They also help send signals between parts. When all the parts are connected well, your machine can work better. Most cables you find in a store come in one size or shape. But all machines are different. Custom made cables made just for your machine are a wise choice. These cables are built to match your machine. They last longer, fit better, and help keep your work safe. When you use the right cable, your machine will run smoother and break less often. Are Custom Cable Assemblies Essential Custom made cables are special cables made for one job. They are not like the regular cables you buy at the store. With custom cables, you can choose what kind of wire you need, how long it should be, what kind of plug it has, and what type of cover it uses. This makes sure the cable fits your machine perfectly. A custom cable connection means every part fits just right. No loose ends or wires twist too much or bend in evil ways. When you use wire custom in your machine, it helps you save time and avoid mistakes. You won’t need to cut or fix the cables. They will be the correct size from the start. A cable assembly is a group of wires that make one strong cable. These cables come ready to use. You can just plug them in and start your machine. These cables are also very safe. They are made to block noise, fight fire, and even stay safe around water. Each cable goes through many tests to ensure it works well before use. This helps stop problems before they start. Good Things About Using Custom...

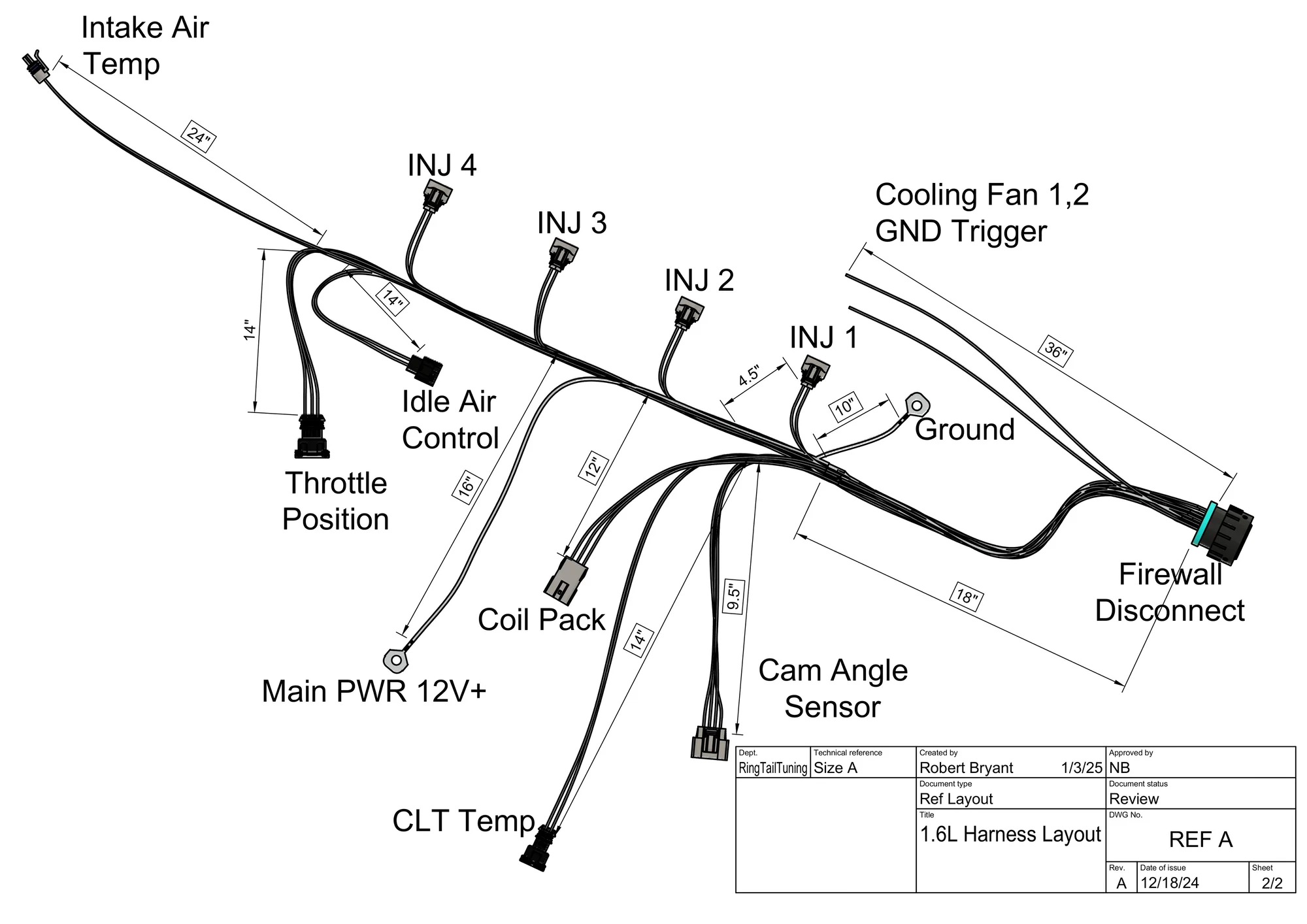

Read More »How to Use a Wiring Harness| Custom Cable Harness

Wiring harnesses or cables are crucial parts of contemporary electrical systems. They are pivotal in various industries, organizing, protecting, and streamlining electrical circuits. Whether you’re an engineer, technician, manufacturer, or hobbyist, understanding how to use a wiring harness effectively can improve your project's reliability, efficiency, and safety. These harnesses streamline complex wiring systems into an organized, easy-to-manage assembly, providing a structured and efficient power and signal distribution solution. This article will explore how to use a wiring harness, the advantages of custom cable harnesses, best practices for integrating them into your projects, and tips for selecting and implementing them in various projects.\ About Wiring Harness? Electrical cables or wires that carry signals or electricity are assembled in a wiring harness. Straps, cable ties, sleeves, or electrical tape secure these wires into a neat bundle. The harness may include connectors, terminals, and protective sheaths tailored to the application's needs. Instead of having a tangled mess of individual wires, a harness bundles them into a neat assembly, improving safety, performance, and installation efficiency. Several industries use wiring harnesses, including: Automotive Aerospace Industrial machinery Consumer electronics Telecommunications Medical equipment How to Use a Wiring Harness Using a wiring harness involves planning, installation, and testing. So you have to know the proper way to use it. For your better understanding, i will share here a step-by-step guide: Understand Your Requirements Start by reviewing your system's electrical schematics. Identify the number of connections, types of signals (power, data, ground), current loads, and environmental conditions. Key questions to ask: What voltage and current will be running through the harness? How many connectors or terminations are needed? Will it be exposed to water, oil, or extreme temperatures? Does the EMI protection of the harness require shielding? Choose or Design a Suitable Harness You can choose a pre-configured...

Read More »

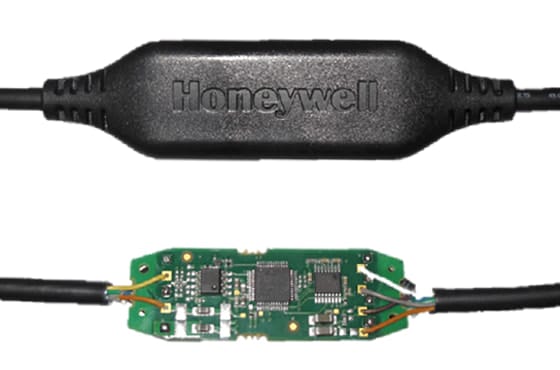

The custom-molded cable assembly plays a critical role in the reliability of electronics and electrical systems that work flawlessly and withstand harsh environments, mechanical stress, and continuous use. These custom-moulded cables provide durability, protection, and performance for medical devices and industrial automation in aerospace, telecommunications, and many other sectors. But what exactly is it, and why is it so important? Let’s take a closer look. What Is a Custom Molded Cable Assembly? The connectors and cable junctions of a custom-molded cable assembly are covered with a molded substance, usually rubber or plastic, that is made to meet the application's demands. This molding method offers improved protection, robustness, and dependability, particularly in settings where conventional off-the-shelf cable assemblies might not be enough. These assemblies' length, connector type, shielding, and form factor are all specially tailored to the particular purpose. Over-molding is crucial here. A molten substance, like PVC, TPU, or TPE, is injected around the connection and cable interface. The outcome is a cable that can tolerate mechanical strain, is impervious to wear, and is sealed against moisture. Why Choose Custom Molded Cable Assemblies? Durability in Harsh Environments Custom-molded cables are made to last, whether exposed to dampness, chemicals, UV rays, vibration, or extremely high or low temperatures. This molded material acts as a protective shield, making it ideal for industries such as sterilization, vibration and impact resistance, chemical and oil resistance, waterproofing, and UV resistance in many sectors. Enhanced Strain Relief By adding structural strength to the cable-to-connector transition, custom molded connections lessen wear and tear caused by twisting, bending, and pulling. The assembly's lifespan is increased, and this additional strain alleviation decreases maintenance expenses. Improved Aesthetics and Branding Molded assemblies offer a clean, professional appearance that reflects quality and attention to detail. You can customize your company logos,...

Read More »Professional Cable Assemblies Manufacturer in Changsha | Custom Wire Assemblies

From industrial automation, medical equipment, automotive systems, and consumer electronics, many aircraft cable assemblies are the unseen heroes that power devices, machinery, and communication systems. High-quality cable assemblies can ensure seamless electrical performance and safety in today's technology-driven world. We specialize in custom wire assemblies and services as a worldwide professional cable assemblies manufacturer. With our wide brand reputation, we have been providing this service for a long time. We offer premium solutions to satisfy the demands of our international clients. Why Cable Assemblies Matter cable assemblies manufacturer are commonly joined together to transport electricity properly. They are engineered to endure harsh environments, electromagnetic interference, and mechanical stress where regular cables can't. Improved organization and safety Enhanced durability and resistance Streamlined installation and maintenance Customization for specific applications Our Expertise as a Leading Manufacturer Our experience spans over a decade with advanced machinery, a highly skilled workforce, and a rigorous quality control system. Each industry has challenges, and we work to fulfill our stringent compliance and durability challenges. Our service areas: Automotive: High-performance cable harnesses for infotainment, engine control, lighting, and battery systems Medical: Precision wire assemblies used in diagnostic devices, imaging equipment, and surgical tools. Industrial: Durable cable assemblies designed for robotics, automation, and heavy machinery. Consumer Electronics: Compact, reliable assemblies for laptops, wearables, and smart appliances. Renewable Energy: UV-resistant, waterproof solutions for solar panels and wind turbines. Custom Wire Assemblies: Designed for Unique Needs Since each application is unique, off-the-shelf solutions frequently do not work, so we provide custom wire assemblies to meet your specifications and requirements. We have a qualified engineering team member. Who can 100% ensure you are provided the right design, material selection, and assembly techniques, whether the length, gauge, connector type, shielding, or jacketing. We also offer prototyping services so our clients can...

Read More »Injection molding cost structure compared to 3D printing

When you want to make a product, you need to choose how to make it. Two ways are 3D printing and injection molding. 3D printing is good when you only need a few parts. It saves money at the beginning. But if you need many parts, it can take a long time and cost more. Injection-molding is different. You need to make a mold first, which costs more initially. But once you have the mold, you can make many parts quickly. This saves money if you need to make hundreds or thousands of items. So one is better for small jobs, and the other for big ones. Injection Molding It is a quick way to make many plastic parts look the same. It uses a strong mold made from metal like steel or aluminum. Hot plastic is pushed into the mold, cools down, and gets hard. When it's ready, the mold opens, and the part pops out. Injection molding process steps: Close the mold tightly. Push in the melted plastic. Let the part cool inside. Open the mold again. Take out the finished part. Injection molding method is fast. You can make hundreds or even thousands of parts in one day. This method is best when you need many parts, not just one or two. What Is a Mold and Its Cost A mold is a hard metal tool that shapes plastic into your part. It is made from strong metals like steel or aluminum, so it lasts a long time. Making a mold takes time and special skills. Inside the mold, tiny plastic mold parts help move the plastic, cool it down, and remove it when it's done. An innovative plastic mold design makes the job easier and cheaper. Designing for injection molding is a big part of...

Read More »Roles do the Custom OBDII connector play in communications

Car uses a special plug called OBDII to send that information. This plug is usually under the dashboard. A custom OBDII connector is even more helpful. It connects the car to tools, apps, or phones. It helps people read what the car is doing. This can help fix problems faster. It can also help check how well the car is working. It is a small tool, but it does a tremendous job. It allows drivers and repair shops to take care of the car. Custom OBDII connector: Why Every Car Needs One The Custom OBDII connector is a small plug found under the dashboard in most cars made after 1996. Even though it's a tiny part, it does a massive and essential job. This plug helps special tools connect to your vehicle to see how everything works inside. These tools are used by car repair shops and sometimes even at home. The plug looks like a small rectangle and has 16 tiny holes called pins. Each pin has its own job: Some send power, some send messages, and some send warning signals when something goes wrong. This pinout is called the OBD pinout. Most cars have the same pin layout, so tools can work with any car. When you use a tool or scanner, it has to plug into the connector correctly. These tools use an OBD connector or an OBD2 connector, which fits into the OBD2 connector on your car. When they connect, the tool quickly grabs data from the vehicle and shows you what is happening. It's fast and beneficial. Some people call this plug by different names like connector obd, connector obd2, or obd obd2 connector, but they all mean the same thing. This little plug helps your car talk to machines. It's used...

Read More »How does low pressure molding protect sensitive electronics

Low pressure molding is a smart way to keep small parts safe. Some small parts in tools or machines are straightforward to break. This molding uses soft, gentle material to cover the part. It wraps around it without pressing too hard. It keeps water and dust out so the part stays clean. It also keeps it safe from drops or bumps. When parts are protected this way, they can last a long time. Low-pressure molding is great for electronics and other small parts. Why Small Electronics Need Extra Care Small electronics, like sensors and wires, can stop working if they get too hot or are hit. Dirt, water, or even small shakes can break them. Low-pressure molding makes a strong coat that wraps around these parts. This coat keeps water, dust, and even air away. It’s like a rain jacket for electronics. It helps the parts last longer and stay safe, even if the device is outside or used often. Low Pressure Molding Is Safer Than Old Moldings Old methods, like injection molding machines, push plastic into a shape with a lot of force. That is okay for big parts, but it’s not good for small and breakable pieces. Low-pressure molding uses less push and less heat. This keeps the parts safe and stops them from cracking or melting. It also makes fewer mistakes, so you throw away less plastic. That means you save time and money. Clean & Easy Way to Make Safe Plastic Parts Low pressure molding does not take a long time. You can make parts quickly and without making a mess. It does not splash plastic all over. The space where you work stays neat. It is much easier to use than an old plastic injection molding press. You can work faster and keep your place...

Read More »Custom Wire and Cable: In industrial automation systems

Custom Wire and Cables are made to fit machines just right. They help machines do their jobs faster and better. When wires and cables fit well, machines do not stop or break. These wires help prevent problems before they start. They help keep people and tools safe while working. Custom wires are made for each job, so they work best. Wires Made to Match Each Machine's Shape Every machine is different and has different needs. Some need wires that bend and move often. Others need wires that can take heat, cold, or dirt. A custom wiring harness is made to fit your machine's shape, size, and function. It keeps wires safe, neat, and exactly where they should be. This stops wires from pulling loose or getting damaged. When wires fit right, machines work better, last longer, and are easier to repair. Workers save time and stay safer when the wiring is well organized. Keep Wires Neat, Clean, and Safe by Grouping Them Loose or hanging wires can be messy and dangerous. They might cause someone to trip or even cause a fire. Using a bundle of cables or bundle wire keeps the wires tied together in neat paths. This makes machines look clean and makes it easier to fix problems when they happen. Bundled wires help you find problems fast, saving time and money. They also protect wires from damage and keep the machines looking good and running right. Use Strong Steel Cables to Lift, Pull, & Hold Heavy Parts Machines in many factories need to lift, pull, or hold heavy parts. These tasks require robust wires like steel cable wire and steel tension cables. These cables are made from tough steel and carry heavy loads without breaking. They are used in jobs where safety is essential because they will...

Read More »What are common problems with Automotive Wire Harnesses

A good Automotive Wire Harness automotive setup means all the wires are wrapped and put in places where they are safe. They should not get too hot or rub on other parts. If placed right and checked often, they can last a long time. But they can get weak, break, or stop working over time. In this guide, we'll discuss the many things that can go wrong with car wiring harness automotives and how to stop them before they cause trouble. Bad Connections in Plugs & Ends That Stop Power In every car, the wires end in plugs that go into other parts. These plugs are called connectors or terminals. If one of these plugs gets loose, rusty, or dirty, it can stop the wire from sending power. That means the part it connects to may stop working or work only sometimes. For example, if you see the car lights blinking, the radio turning off, or the power windows getting stuck, this could be a sign of a bad connection. These problems can come and go. To help fix this, you can use connectors that seal tight and keep out water. Use grease that is especially made to prevent rust. Wires That Rub & Break from Moving or Vibration When the car moves, the wires move, too. They can rub a lot if they are too close to metal or other rough parts. This rubbing takes off the soft cover on the wire, called insulation. When that cover is gone, the metal wire inside can touch the car or others. In bad cases, this can spark, blow a fuse, or even start a fire. This rubbing is popular for the old cars and offroad cars. Use soft rubber to cover the plastic clips to prevent the vibration....

Read More »