How to Use a Wiring Harness| Custom Cable Harness

By hdhhd shhsbbs / 2025年6月1日

How to Use a Wiring Harness?

Wiring harnesses or cables are crucial parts of contemporary electrical systems. They are pivotal in various industries, organizing, protecting, and streamlining electrical circuits. Whether you’re an engineer, technician, manufacturer, or hobbyist, understanding how to use a wiring harness effectively can improve your project’s reliability, efficiency, and safety.

These harnesses streamline complex wiring systems into an organized, easy-to-manage assembly, providing a structured and efficient power and signal distribution solution.

This article will explore how to use a wiring harness, the advantages of custom cable harnesses, best practices for integrating them into your projects, and tips for selecting and implementing them in various projects.

About Wiring Harness?

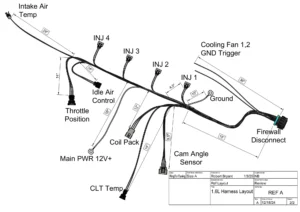

Electrical cables or wires that carry signals or electricity are assembled in a wiring harness. Straps, cable ties, sleeves, or electrical tape secure these wires into a neat bundle.

The harness may include connectors, terminals, and protective sheaths tailored to the application’s needs. Instead of having a tangled mess of individual wires, a harness bundles them into a neat assembly, improving safety, performance, and installation efficiency.

Several industries use wiring harnesses, including:

- Automotive

- Aerospace

- Industrial machinery

- Consumer electronics

- Telecommunications

- Medical equipment

How to Use a Wiring Harness

Using a wiring harness involves planning, installation, and testing. So you have to know the proper way to use it. For your better understanding, i will share here a step-by-step guide:

Understand Your Requirements

Start by reviewing your system’s electrical schematics. Identify the number of connections, types of signals (power, data, ground), current loads, and environmental conditions.

Key questions to ask:

- What voltage and current will be running through the harness?

- How many connectors or terminations are needed?

- Will it be exposed to water, oil, or extreme temperatures?

- Does the EMI protection of the harness require shielding?

Choose or Design a Suitable Harness

You can choose a pre-configured Wiring Harness or design a custom cable harness with a manufacturer. Customization includes:

- Wire gauge and color

- Connector types (e.g., Molex, JST, Deutsch)

- Labeling for easy identification

- Protective jackets (PVC, braided sleeving, heat-shrink)

- Routing paths and breakout points

Install the Wiring Harness

Installation should follow these guidelines:

- Use clamps or clips to secure the harness and prevent movement.

- Ensure bend radii are within recommended limits to avoid wire fatigue.

- Wiring should be kept away from sharp edges and sources of intense heat.

- Connect terminals firmly to avoid loose connections.

- Use strain reliefs where necessary to reduce stress on connectors.

Test the Installation

Once installed, perform electrical tests:

- Continuity testing ensures all connections are correctly established.

- Insulation resistance checks for shorts or leaks.

- Load testing simulates operational conditions to verify performance.

Connect and Validate

After physical installation:

- Connect all terminals according to the wiring diagram

- Power on the system and monitor behavior

- To guarantee correct operation and signal integrity, use diagnostic tools.

- Perform a final inspection to check for loose fittings or overheating

How to Source a Custom Cable Harness

Choose the Right Manufacturer

Look for a supplier that:

- Understands your industry

- Offers prototyping and testing services

- Is ISO-certified or compliant with relevant quality standards

- Provides detailed design consultations

Provide Clear Specifications

Be ready to share:

- Electrical schematics or block diagrams

- Environmental requirements

- Connector preferences

- Any industry-specific standards

As a professional manufacturer, we can help optimize your design for cost, durability, and manufacturability.

Tips for Harness Design and Use

Plan Cable Routing Early: Design cable paths alongside mechanical layouts to avoid clashes and ensure sufficient space for bends and connectors.

Label Everything: Use printed labels, color codes, or heat-shrink markers to identify connections easily, especially in complex systems.

Think Ahead for Maintenance: Design harnesses with serviceability in mind. Quick disconnects and modular layouts can save hours during repairs or upgrades.

Account for Future Expansion: Leave spare conductors or connector ports in your design to allow system upgrades without needing a full redesign.

Document Thoroughly: Always keep detailed schematics, pinouts, and test records. These are invaluable for training, troubleshooting, and audits.

Custom Cable Harness vs. Standard Wiring: A Comparison

| Feature | Custom Cable Harness | Standard Loose Wiring |

| Installation Time | Fast and efficient | Time-consuming |

| Risk of Error | Low | High |

| Aesthetics and Organization | Neat and clean | Messy |

| Durability | High (based on materials) | Moderate |

| Cost | Higher upfront, lower long-term | Lower upfront, higher labor cost |

| Flexibility | Designed to exact specs | Requires on-site adaptation |

Best Practices for Custom Cable Harness Usage

- Work with a Reputable Manufacturer

Partner with a provider with industry experience that can ensure high quality, certification, and performance. - Document Everything

Always have a detailed schematic, parts list, and usage guidelines. Proper documentation is required for installation, upkeep, and troubleshooting. - Label Wires Clearly

Use heat-shrink labels, tags, or color codes to easily identify wire. This prevents connection errors and simplifies repairs. - Consider Future Upgrades

Design the harness with extra connectors or slack for anticipated upgrades or expansions. - Maintain Proper Grounding and Shielding

Proper grounding and EMI shielding are necessary for signal integrity and safety, especially in high-noise environments. - Regular Maintenance and Inspection

Periodically inspect installed harnesses for signs of wear, corrosion, or damage, especially in mobile or outdoor applications.

Typical Applications of Wiring Harnesses

Wiring harnesses are found in virtually every electrical or electronic industry. Key applications include:

- Automotive: Engine compartments, dashboards, lighting systems, and infotainment.

- Aerospace: Avionics, instrumentation, flight control systems.

- Medical Devices: Imaging systems, surgical instruments, diagnostic equipment.

- Industrial Equipment: Automation systems, robotics, CNC machines.

- Consumer Electronics: Gaming consoles, home appliances, smart devices.

- Telecommunications: Data centers, networking hardware, servers.

- Marine: Navigation systems, communication equipment, and lighting.

Benefits of Using a Custom Cable Harness

Custom cable Wiring Harness offer multiple advantages over traditional loose wiring systems:

Simplified Installation

Wiring harnesses are pre-assembled to exact specifications, making installation quick and foolproof. This reduces labor costs and minimizes the chance of wiring errors.

Enhanced Safety

Bundled wires are easier to manage and protect, significantly lowering the risk of shorts, electrical fires, and loose connections.

Durability and Protection

Harnesses are designed to endure harsh conditions, heat, moisture, vibration, or chemicals, depending on the materials used. Protective sheathing and insulation ensure a longer service life.

Space Optimization

Harnesses help optimize space within electrical cabinets, vehicle dashboards, control panels, or other enclosures by maintaining an organized wire routing.

Customization and Scalability

Custom harnesses allow you to design the layout, choose materials, and specify connector types that precisely match your application’s needs.

Final Thoughts

Custom cable Wiring Harness take this further by aligning perfectly with your project’s requirements. By partnering with a knowledgeable manufacturer and adhering to best practices, you can enjoy efficient installation, reliable performance, and long-term success.

A custom cable harness is a wise investment for any electrical or electronic project. It offers benefits like simplified installation, increased safety, and improved durability. If you need help designing or sourcing a custom cable harness, don’t hesitate to contact our team. We specialize in building precision cable assemblies tailored to your unique needs.