Steps to Design a Custom Wire Harness

A custom wire harness is a set of wires that are connected together. These harnesses are used in many machines to make signal connections. They help everything work right. If one wire is wrong, many parts can stop working. So, making a good wire harness is very important. It is like building a safe path for power and signals to travel. If the path is broken, things will not work. That's why we must follow each step carefully. At QL-Custom Technology Ltd. is the top of the electrical harness manufacturers. We have a very experienced and skilled team. We supply premium quality custom wire harnesses to many places. Know the Requirements Knowing the customers requirements is essential. We ask many helpful questions like: Where will the harness be used? Will it be placed inside a machine or outside? Will it face water, heat, cold, or dust? Will the wires move around a lot or stay still? We also need to know what the harness will do. Will it power lights? Motors? Will it carry a lot of power or just a little bit? These things help us know how strong the wires need to be. They help us pick the best connectors and protective parts to use. Draw the Design or Ready the Plan After gathering all the information, we begin to draw the custom wire harness design. We use computers and special software to help us make a clear and detailed plan. This drawing shows where every wire will go and how everything connects together. We also choose strong wires, trusted connectors, and reliable materials. We ensure the design fits nicely inside the machine where it will be used. The goal is to make cable harnesses that are safe, neat, and work well every time. Make a...

Read More »Automotive wire harness: best heat resistant materials

Cars can get very hot when running, especially when the engine is working hard or the weather outside is warm. The heat from the engine, the battery, and other parts like the air conditioner and lights spreads throughout the car. This heat moves through the car and touches many automotive wire harnesses. The automotive wire harnesses can get damaged if they are not made of strong, heat-resistant materials. They might melt or break. In terrible cases, hot wires can even cause a fire, which is very dangerous. When a wire melts or breaks, the part of the car it powers may stop working. This could mean the engine won’t start, the lights might go off, or even the brakes could fail. Fixing these problems can cost a lot of money. That’s why it’s essential to use wires made from materials not damaged by heat. These wires help keep the car safe and working correctly for a long time. QL-Custom Technology Ltd. builds automotive wiring harnesses that are made to handle heat. These wires are safe, strong, and used in many cars. We ensure they last long and work well even in hot car parts. Best Heat-Resistant Automotive wire harness Materials Some materials are much better than others when handling heat inside a car. These materials are used in wires that must stay strong and safe in hot places. Here are the most common and trusted materials used for this job. XLPE (Cross-Linked Polyethylene) XLPE is a type of plastic that is very strong and can handle heat very well. It is often used near engines and other hot parts in the car. It also works well when a lot of power goes through the wire. This material does not break or crack easily, even if it gets hot...

Read More »Automotive Wire Harness in Vehicle Infotainment Systems

New cars have many cool tools inside. They have screens, music systems, GPS, voice control, and rear-view cameras. All of these tools use Automotive Wire Harnesses to connect to each other. But having many loose cables can be a mess. That is why a wire harness is used. A wire harness puts all the wires in one place. It keeps them neat, safe and organized. This helps each tool get the power and data it needs. When wires are in the right place, the tech in your car works better. Let's look at how wire harnesses help run all these fun and helpful tools in your vehicle. Automotive wire harnesses are the main item that works from behind to run these tools. These wires move power and information to where they are needed. They must be strong, safe, and neatly arranged to avoid trouble. Because of the wiring harness in a car all the system works properly . This is where QL-Custom Technology Ltd. comes in. They are a top company based in China that makes strong, high-quality wire harnesses for car systems. Their products help infotainment systems in cars work the right way. They send their parts to many countries, ensuring people everywhere enjoy the best driving experience. What Is Automotive Wire Harness It is a bundle of wires that works together to run the vehicle system smoothly. Each wire in the harness does an important job. Some send sound to the speakers. Some bring images to your screen. There are many kinds of harnesses that work for the switches of the vehicle. Car wiring harness combined all the wires and kept them safe. In this way all the vehicle systems work properly and stay connected. And it saves space inside the vehicle. Different jobs...

Read More »Obeying Quality Control Measures in Custom Wire Harness

Making a perfect custom wire harness is not just about connecting wires. It is about making sure every single part is done right from the start to the end. Even small mistakes can cause big problems later. Examples are machines breaking or even dangerous fires. Good quality work means the wires will be safe, strong, and work for a very long time without issues. It ensures everything works well in cars, robots, hospitals, etc. Are you seeking a brand that checks every detail & never misses anything vital? Then you should learn about QL-Custom Technology Ltd. They are experts who take great pride in every project they complete. They make sure each product is strong, safe, and perfect for your needs. Is Quality Control Important in Custom Wire Harness Quality control is like a big safety net that catches problems before they reach you. For things like custom automotive wiring and custom automotive wiring harness, it is even more vital. Bad wiring can cause serious accidents. Reasonable quality control makes sure every wire is strong, safe, and can handle the job it needs to do. Without these checks, wires can break, machines can stop working, or fires can start. There is no room for mistakes in places like cars, planes, and hospitals. Good checking also saves a lot of money because it stops problems early before they become big. It keeps everything safe, saves time, and ensures the custom wiring harnesses work correctly. Does Good Companies Check Their Work Good companies like QL-Custom follow a very careful plan to check everything. They do not just start building without thinking. First, they test all the parts and wires they get from others to make sure they are good. They only use the best parts. During building, they watch every...

Read More »Automotive Cable Harness Manufacturers in EV Development

Automotive Cable Harness Manufacturers build these harnesses for EVs have an essential job. They ensure the wire sets are strong, safe, and work well. These wires help the car move, stop, and turn. They power the lights, screens, and sensors. They also allow the brakes and battery systems. Without a wire harness, the car can't run. That's why automotive cable harness manufacturers play a significant role in making safe and high-quality EVs. What Is a Cable Harness A cable harness is a group of bundled and wrapped wires. It helps to keep the cables in the right place and stops them from getting damaged. The harness keeps the cables safe and allows the car to work better. Electric cars need more wires than gas cars because they have more electric parts. The wires must be small but very strong. They must work well in hot, cold, and even rain. The cable harness helps protect the wires from all these things. Without a strong harness, the wires might break or move around, and the car might stop working. Are Automotive Cable Harness Manufacturers Vital Cable and harness manufacturers make cable harnesses & play a big role in building electric cars. They design the wire systems for each kind of car. No two vehicles are identical, so every harness must fit just right. Automotive cable harness manufacturers also test the wires to make sure they work well. They check that the electrical wiring harnesses automotive will last long, even after many years of use. The harness must be safe and work perfectly, or the car could stop running. These automotive cable harness manufacturers help make EVs lighter, too. Lighter cars can go farther without needing a charge. Why Good Quality Matters If the wires in a car are bad, the car...

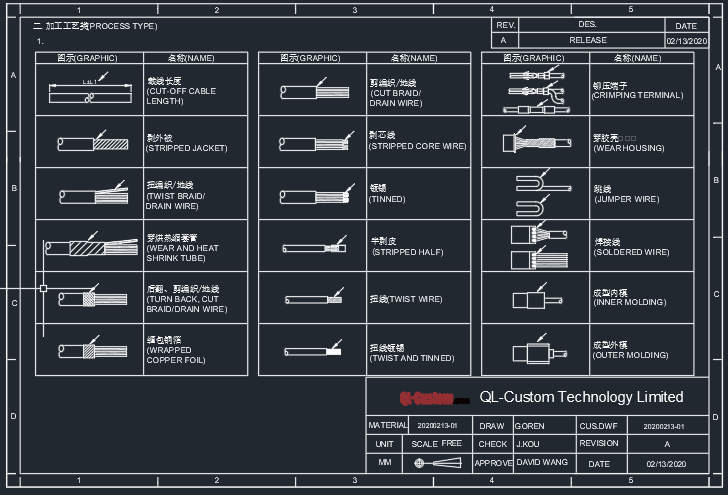

Read More »The Wire Cable Harness Drawing Standards

Importance of the Wire and Cable Harness Drawing In the realm of modern engineering and design, wire cable harness drawings hold paramount importance. These drawings serve as blueprints that detail the intricate layouts of wiring systems, ensuring that each component is correctly connected and functioning as intended. Without precise drawings, the likelihood of errors increases, which can lead to system failures, costly repairs, and even hazardous situations. For engineers and designers, mastering wire cable harness drawing standards is not just an option but a necessity to ensure the reliability and safety of their projects. Wire cable harness drawings are essential for several reasons. Firstly, they provide a visual representation of the electrical connections and layout, making it easier for engineers to understand and communicate the design to others involved in the project. This includes manufacturers, technicians, and quality control personnel. A well-drafted harness drawing eliminates ambiguities, reducing the risk of misinterpretation and ensuring that everyone is on the same page. Secondly, these drawings play a critical role in the manufacturing process. They guide the assembly of the wire harness, specifying the lengths of wires, the types of connectors, and the routing paths. This level of detail is crucial for ensuring that the harness fits correctly within the physical constraints of the application, whether it's in an automotive, aerospace, or industrial setting. Accurate drawings help streamline the production process, minimize errors, and enhance the overall quality of the final product. Mastering Wire Cable Harness Drawing Standards: A Comprehensive Guide for Engineers and Designers To master wire cable harness drawing standards, engineers and designers must familiarize themselves with industry norms and best practices. These standards are established by organizations such as the International Electrotechnical Commission (IEC), the Institute of Electrical and Electronics Engineers (IEEE), and the National Electrical Manufacturers Association (NEMA). Understanding...

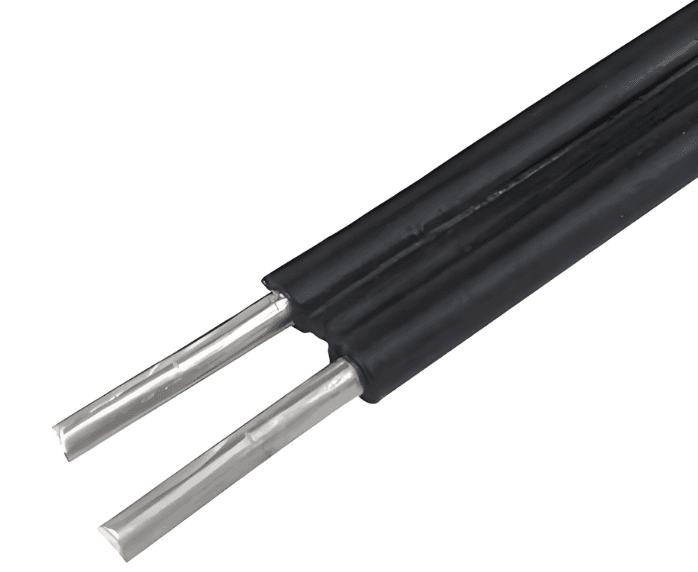

Read More »Teflon PTFE PFA flat ribbon zip wire and cable

The Power of Teflon: A Deep Dive into PTFE and PFA Ribbon Zip Wires and Cables In the realm of modern electrical engineering, Teflon has emerged as a transformative material, fundamentally altering our understanding and usage of wires and cables. Polytetrafluoroethylene (PTFE) and Perfluoroalkoxy (PFA), the scientific names for these advanced polymers, have set new benchmarks in terms of performance and reliability. With their extraordinary heat resistance, chemical stability, and electrical insulation properties, PTFE and PFA ribbon zip wires and cables are indispensable in high-performance environments. As the demand for superior electrical components continues to surge, delving into the complexities of Teflon-based cables unveils how these materials are more than just conduits; they are crucial to ensuring safety, efficiency, and longevity in a myriad of applications ranging from consumer electronics to critical industrial systems. Understanding the profound impact of PTFE and PFA on the electrical industry requires a comprehensive exploration of their unique properties, the production processes involved, the reasons behind their distinct features, and their extensive range of applications. This in-depth analysis will illuminate how these materials have revolutionized electrical wiring and cabling, providing the backbone for technological advancements across numerous sectors. The Unique Properties of PTFE and PFA PTFE and PFA possess a set of remarkable properties that make them stand out in the world of polymers. One of the most notable characteristics of PTFE is its exceptional thermal resistance. Capable of withstanding temperatures up to 260°C (500°F), PTFE does not degrade or lose its mechanical properties under extreme heat. This makes it an ideal material for applications where high temperatures are a constant concern. Similarly, PFA shares this thermal resilience but offers slightly better mechanical strength and flexibility, making it suitable for dynamic environments where cables need to endure both heat and motion. Another critical property...

Read More »Key Parts of a Modern Automotive Wire Harness

Automotive Wire Harness is a vital part of the vehicle system. Without this the vehicle system will not run. These harnesses also need many kinds of components. With the proper kinds of parts the harness will provide top quality services. So before selecting a harness checking the components is necessary. QL-Custom Technology Ltd. is a company that makes these essential Automotive Wire Harnesses. They are very good at it and have many years of experience. Their team works with care and knows how to make strong, safe, and smart wire harnesses. They ship their parts to many places around the world. If you are looking for a trusted team that makes top-quality harnesses, QL-Custom is the right choice. Essential Parts of a Automotive Wire Harness Wires and Cables Wires are like tiny roads inside the car. They move power and messages from one part to another. Most wires are made from copper. Copper is strong and safe. It carries power well. Some cables may use other light metals. Every wire has a cover made of plastic or rubber. This cover keeps the wire safe from damage, heat, and water. Good wires need to bend and twist without breaking. This helps them fit in small and tight spaces inside the car. QL-Custom only uses strong, flexible cables that are tested before use. Their vehicle harness can work in both very hot and icy places. These wires last a long time and stay safe in tough spots. Connectors Connectors are small but very important. They join the wires to the car's different parts. Some connectors go to the engine, some to the lights, and some to sensors. They help the wires send the right signals to each part. Some connectors are tiny, and some are large. Some are made to...

Read More »How Automotive Wire Harnesses Have Changed Over Time

Cars use Automotive Wire Harnesses to move power from one place to another. This power helps make lights shine, engines run, radios play, and many more things work. We call these wires a wire harness when they are put together safely and tidily. A wire harness keeps everything working smoothly and safely. It stops wires from getting messy or breaking. It also makes it easier to fix or change things later. Every part of your car that needs power or talks to another part uses a wire harness to work. QL-Custom Technology Ltd. is very good at making these wire harnesses. Our team is competent, skilled, and always follows safety rules. We use new tools and machines to make our products even better. We send our harnesses to many parts of the world. Our harnesses are used in cars, robots, hospital machines, cameras, and more. We constantly check our work to ensure it is strong, safe, and lasts long. People trust us because we care a lot about doing a good job. How Automotive Wire Harness Began in Cars In the past, cars were much simpler. They had very few parts that needed power. The wires were thick and had no colors. There were no labels or tags to help. This made it hard to fix things when wires broke or got mixed up. People often had to guess which wire did what. Each car company used different kinds of Automotive Wire Harnesses. This meant it was not easy to make or repair cars. But cars did not have many extra features, so this was okay for a while. As more things like radios, air conditioning, and safety lights were added, cars needed better wires and better ways to organize them. Automotive Wire Harnesses Got Better As cars grew...

Read More »Design a Custom Wire Harness for Specific Needs

A Custom Wire Harness is a group of wires tied together to send power or information from one part of a machine to another. These wires are placed together neatly to stay safe and easily handled. The harness also includes other vital parts like connectors, coverings, and clips that hold the cables in place and stop them from moving or breaking. It's called ‘Custom Wire Harness’ because it is made for a special purpose. It is built to match your exact needs. Every wire is put in the right place for your machine or project. That means no extra wires getting in the way and no missing wires either. It keeps things clean, helps your machine work better, and ensures it lasts longer. A strong and safe electrical harness can help everything if you're building a robot or working with electronics correctly. A good engine wiring harness is essential for people who fix or build cars because cars move a lot and get hot. Some machines also work in water or dirt, while others must stay clean. A custom wiring harness works in all of these situations because it's made to fit the job. Why Use a Custom Wire Harness All machines and tools are different. Some are small and simple. Others are large and have lots of moving parts. Some tools get hot, some get cold, and others may get wet or dusty. A regular wiring harness might not work well for every situation. That is why a custom wiring harness is the best choice. It is built to do the job right from the beginning. With a custom harness, you get the right shape and size for your tool. The wires stay safe and don't move around too much. The whole thing looks neat and helps the...

Read More »