Steps to Design a Custom Wire Harness

By hdhhd shhsbbs / 2025年5月2日

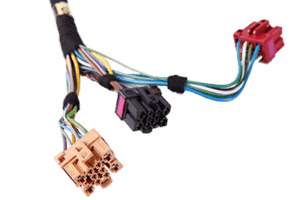

A custom wire harness is a set of wires that are connected together. These harnesses are used in many machines to make signal connections. They help everything work right. If one wire is wrong, many parts can stop working. So, making a good wire harness is very important. It is like building a safe path for power and signals to travel. If the path is broken, things will not work. That’s why we must follow each step carefully.

At QL-Custom Technology Ltd. is the top of the electrical harness manufacturers. We have a very experienced and skilled team. We supply premium quality custom wire harnesses to many places.

Know the Requirements

Knowing the customers requirements is essential. We ask many helpful questions like: Where will the harness be used? Will it be placed inside a machine or outside? Will it face water, heat, cold, or dust? Will the wires move around a lot or stay still? We also need to know what the harness will do. Will it power lights? Motors? Will it carry a lot of power or just a little bit? These things help us know how strong the wires need to be. They help us pick the best connectors and protective parts to use.

Draw the Design or Ready the Plan

After gathering all the information, we begin to draw the custom wire harness design. We use computers and special software to help us make a clear and detailed plan. This drawing shows where every wire will go and how everything connects together. We also choose strong wires, trusted connectors, and reliable materials. We ensure the design fits nicely inside the machine where it will be used. The goal is to make cable harnesses that are safe, neat, and work well every time.

Make a Prototype Custom Wire Harness

Once the design is ready, we make a test version. This sample is built carefully using machines and sometimes by hand. It looks and works like the final harness, but it is just a test. We then try the sample auto wiring harness in a real machine to see how it performs. This step helps us catch any minor problems before we build more.

Test Everything in Custom Wire Harness

Testing is one of the most essential parts of making good car wiring harnesses for cars. We check to make sure the wires carry power the right way. We test it by bending, shaking, and heating it. We want to know if it can be used for real use. We use trusted tools and follow clear test steps. This gives us confidence that the harness is strong, safe, and ready to be used in a real machine.

Improve the Design If Something is Not Right

After testing the sample, we look for ways to improve it. We could use fewer parts, change the layout to save space, or use different materials that are lighter or stronger. We always look for ways to help customers save money without losing quality. Our design team works fast to update the plan. Once we finish all the changes, we are ready to make the whole batch of harnesses.

Build the Real Custom Wire Harness

Now, we begin full production. Our factory uses intelligent machines and skilled workers to build your vehicle wiring harness. The machines cut the wires, strip the ends, and add connectors. Every step is checked to make sure it’s correct. We also have clean work areas and well-trained staff. We inspect the harness at many steps. We want to ensure you get something substantial, safe, and perfect for your machine.

Pack & Ship Custom Wire Harness

Once we finish making the custom wire harnesses, we pack them with care. We use strong boxes and clear labels so the parts are not mixed up or damaged. Then, we ship them to your location as fast as we can. After shipping we stay connected to help you.

Most Specially Designed Custom Wire Harnesses

Waterproof M5-M19 Cable for Wet and Outdoor Use

This waterproof cable is made to keep water from getting inside the wires, even when the weather is terrible. It works well in places with a lot of rain, snow, or mud. This cable protects the electric parts from getting wet or shorting out. It is used in cars, bikes, boats, and outdoor machines. It is powerful and does not break easily.

Omron Switch Cable Relief That Stops Wire Pulling

This little part is very helpful. It holds the wire tightly in place so it doesn’t move or pull too much. If wires get pulled, they can break or stop working. This piece helps prevent that from happening. It protects switches and makes them last much longer. It is strong and can be used in many machines and tools. People use it in cars and as a home tool.

OBD Connector Cables for Fast Car Checks

These special cables let you connect to your car’s computer. You can use them to check what is wrong with the vehicle. They help find problems like engine trouble or sensor issues. Most mechanics use them to fix cars quickly. These cables are also suitable for drivers checking their vehicles at home. They are easy to use. You just plug them in and read the screen. They are small, light, and easy to carry around.

Molded In-Line Fuse Holder to Keep Wires Safe

This part holds a fuse that protects your wires. If too much power goes through, the fuse will stop it. This helps prevent fires or damage to your car. The holder is strong and works in many vehicles like cars, bikes, and trucks. If the fuse breaks, it is easy to change it. This part helps keep your system safe and working. It is smart to use this to keep your wires safe and working well.

Overmolded Battery Plug Cable for Strong Power

It connects with the battery. It keeps the power going to the car. It is used in bikes, tools, and other machines. It does not break easily and works in challenging jobs. It gives steady power even when the weather or road is rough.

Why Pick QL-Custom Technology Ltd.

There are many cable and harness manufacturers, but we stand out because we care. We care about quality. We care about service. We care about making sure you are happy. We only use strong and trusted parts. We test every product. We ship on time. We will keep you updated at every step. We are proud to be one of China’s best harness makers.

Our Full Services & Where Our Harnesses Are Used

We help you from start to finish. That means we help you with the design, make a test sample, build the full order, and then ship it to you. We do it all, so you don’t have to worry. Our team is trained. Our tools are innovative. Our steps are smooth. Working with us is stress-free and straightforward.

Our auto electrical wiring harness is used in so many places. They are used in cars, trucks, robots, hospital tools, army equipment, and clean energy machines. We work with many kinds of businesses and are ready to work with yours.

Our Certificates, Tools & Machines We Use

We are proud of our safety and quality. We have ISO, UL, and RoHS papers. We pass water tests, fire tests, and more. We also give you the proper documents if you need them for your records.

We use strong machines that help us make your car wire harness fast and right. Some machines cut tough shapes. Others bend or crimp the wires. We also do careful hand work for small or special jobs. We use crimping machines, wire cutters, and wire strippers. Then, we check every custom wire harness by testing it to make sure it works well and does what you need.

Fast and On-Time Delivery

We know time is essential. That’s why we check every order carefully. We look at every step and make sure everything is done right. Then, we ship your engine harness fast and safely.

We ship to many countries and always try our best to get your order to you on time, every time.

Making a good custom wire harness for cars or other machines takes time, care, and skill. At QL-Custom Technology Ltd., we are with you through the whole process, from start to finish.

We use strong parts, kind service, and innovative tools.

FAQs

When creating a custom wire harness which is the 1st step?

First step is to make a plan for it. Ask yourself what parts it must connect. Think about where the harness will go inside the car. Will it be near hot areas or cold places? Will it need to bend or move when the vehicle is used?

How do you choose the wire type?

There are many kinds of wires to pick from. Some wires bend very easily. Some are hard and do not bend much. There are various types of cables available. Selecting the exact quality wire for the exact job is vital.

What vital tools are required to design it?

Many easy tools help make a wire harness automotive. Wire cutters are used to cut wires to the size you need. Crimpers press the ends of cables to add connectors. Computers are used to draw maps of where each wire goes. These maps help you see the whole layout. Test boards let you try out your wire plan before you put it in the car. Some tools check if the power flows right.

What is the best way to check wire harnesses?

Use a wire tester tool. This tool checks if power can go from one end of a wire to the other. If the power flows well, the wire is good. If not, the wire may be broken or loose. You need to test each wire one by one. Make sure there are no problems.

Why is planning so important?

Planning helps everything go right from the start. Without a plan, wires may not fit. Wires may go the wrong way or get stuck. They may even break or stop working. A good plan saves money and time. It also keeps the car safe. With a plan, you know where each wire must go and how long it should be.

People Also Ask

In wire harness designing what is the 1st thing to do?

First know the work of the wire harness. You need to find out what things it will power. You also need to learn what it will connect to. Think about the car or machine and what it needs to work. Choose wires based on the power required. You also need to know where the cables will go inside the car. This helps make the plan.

What are the requirements of the wiring diagram?

It helps you understand what wire connects to what part. It also enables you to catch mistakes before building. This makes the work easier and faster. It also saves money because you don’t have to fix it as much later.

What happens after making the diagram?

After the diagram is ready, the next step is to choose the right parts. You pick wires that are strong and safe. You also pick plugs and clips. These parts hold the cables in place. Good parts help the harness last a long time. They also allow it to work better.

Do you need to test the plan?

Yes, you should always test the plan before building. Testing finds mistakes early. It helps make sure everything is safe. If there is a problem, you can fix it before building. This keeps the car or machine from breaking later.

What is a prototype?

A prototype is the first build of the automotive wiring harness. It’s like a test model. You use it to see if the harness works. This is a smart way to catch errors and make changes.

Why do you check wire length?

Each wire must be the right length. With the exact length of wire it will work well. So, measuring each wire is very important.

How do you protect the wires?

There are many ways to protect the cables. Example as you can use tape or wrap. They also help wires last longer, even in hot places.

What is routing?

Routing means planning the wire path inside the car. Wires must move through safe spaces. They should not bend too much. They should not go near hot parts. A good route keeps the cables safe and working.

Do you need to label the wires?

Yes, labels help a lot. They tell you what each wire does. This makes it easy to fix or check the harness later. It also helps if someone else works on it later.

What is the final step?

The last step is to build the complete harness. Put all the wires, plugs, and clips in place. Test the whole harness again. Make sure everything works. Then, it is ready to be installed.

Custom Wire Harness With Diagram