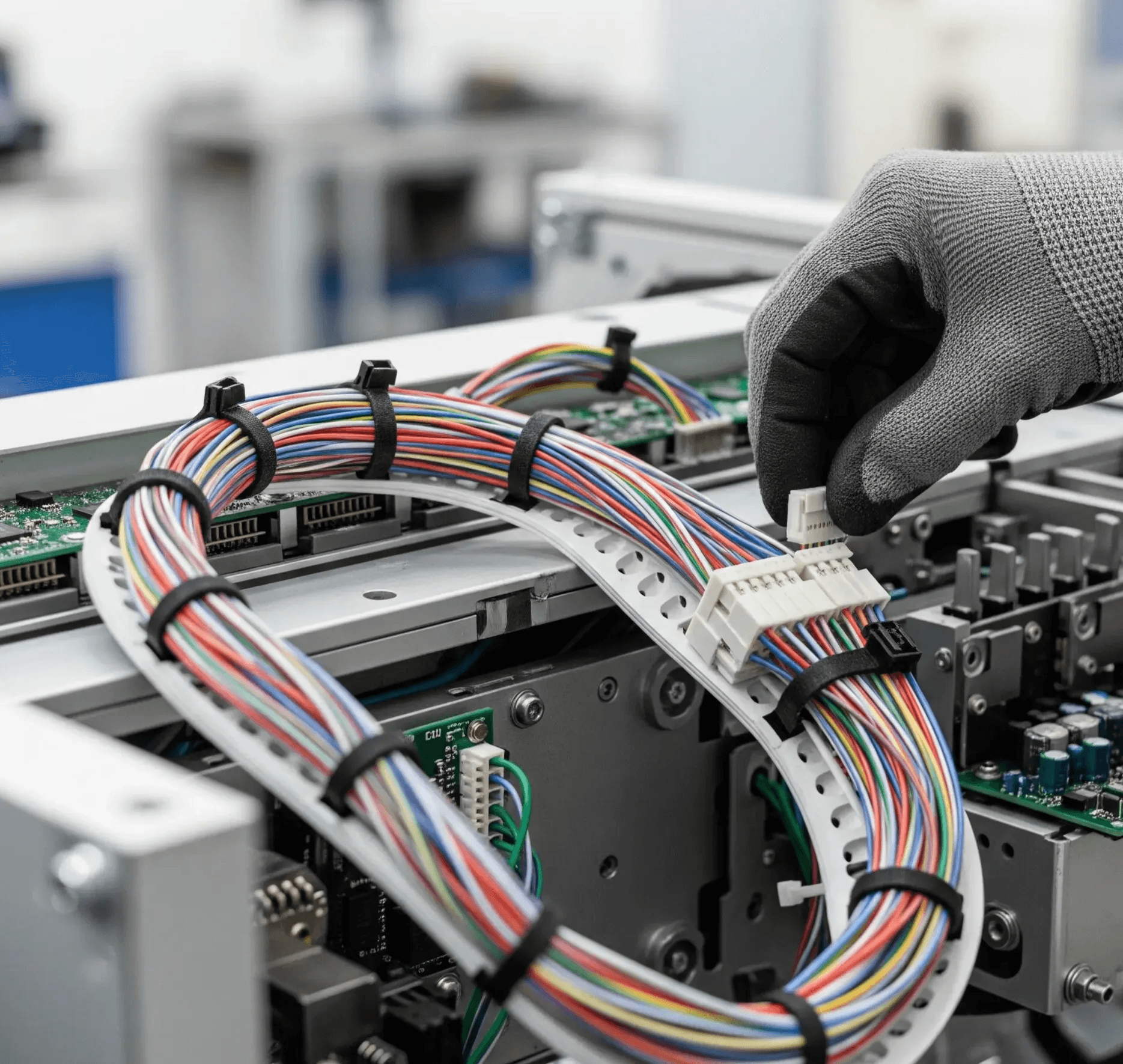

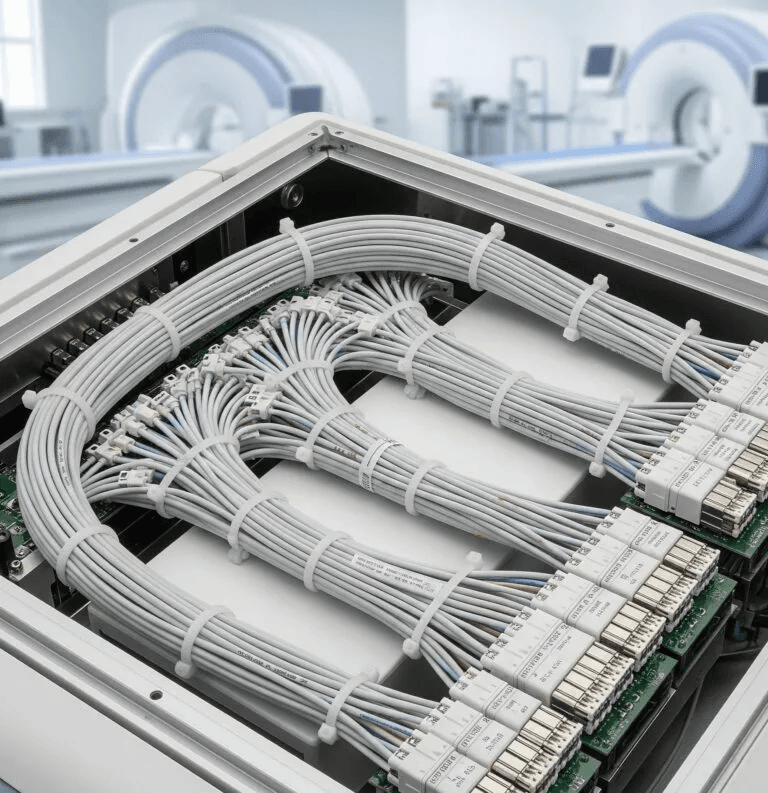

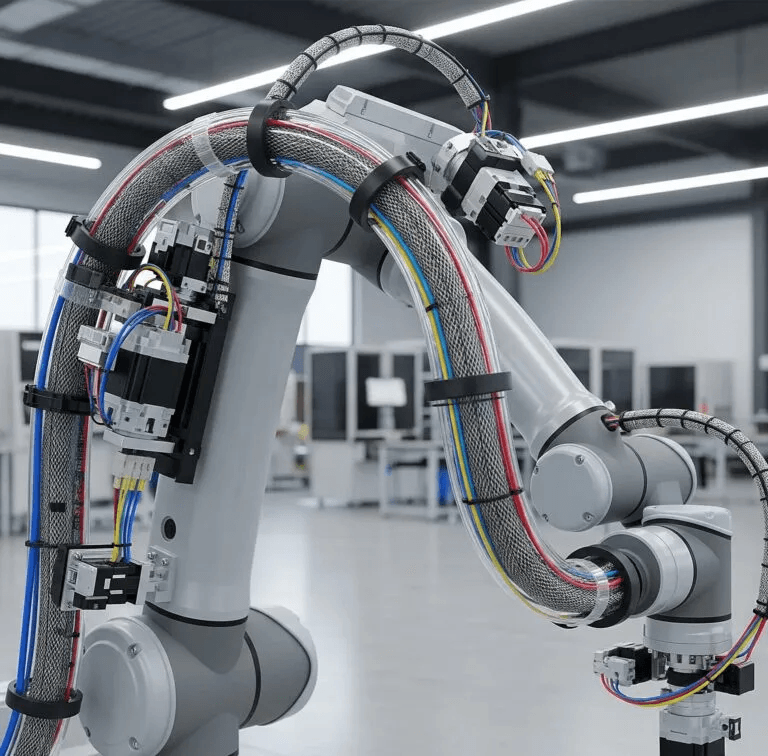

What Is Custom Wiring Harness?

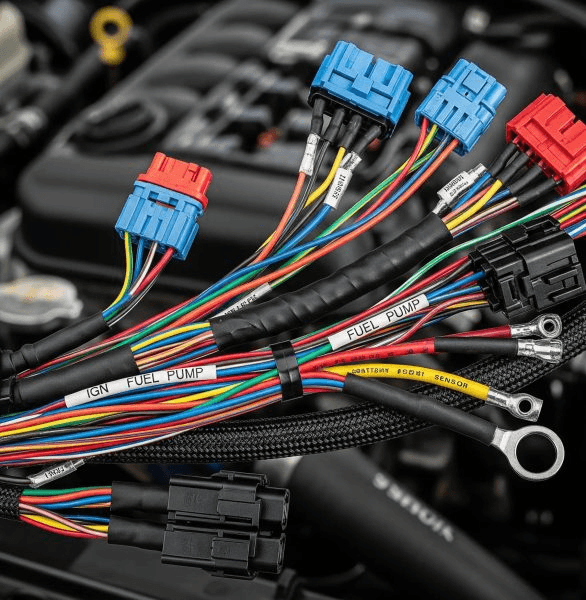

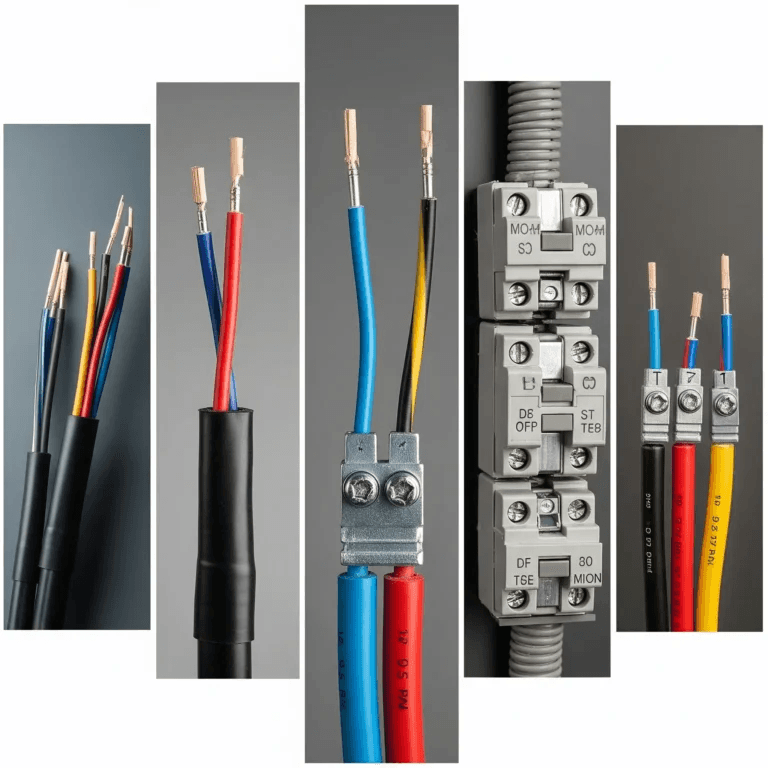

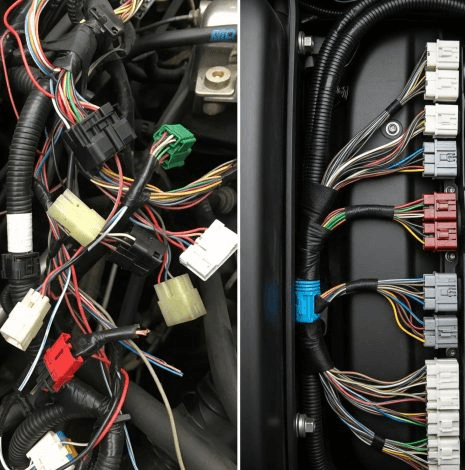

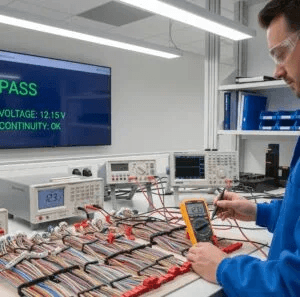

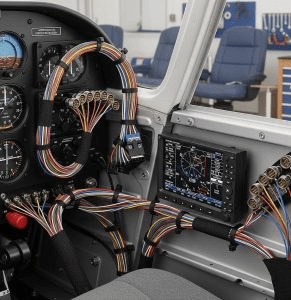

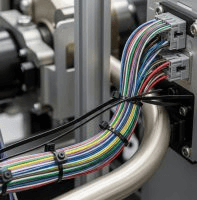

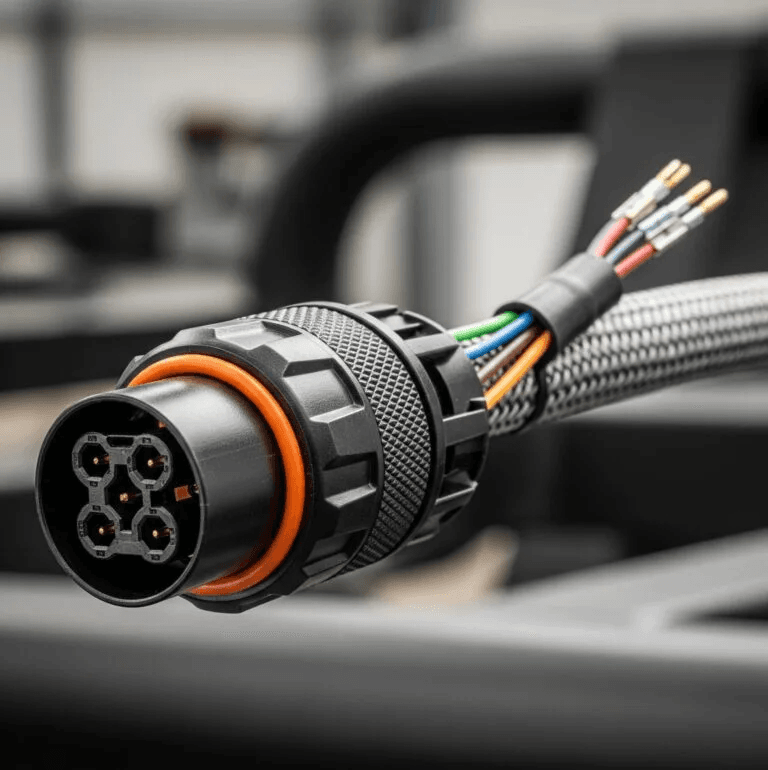

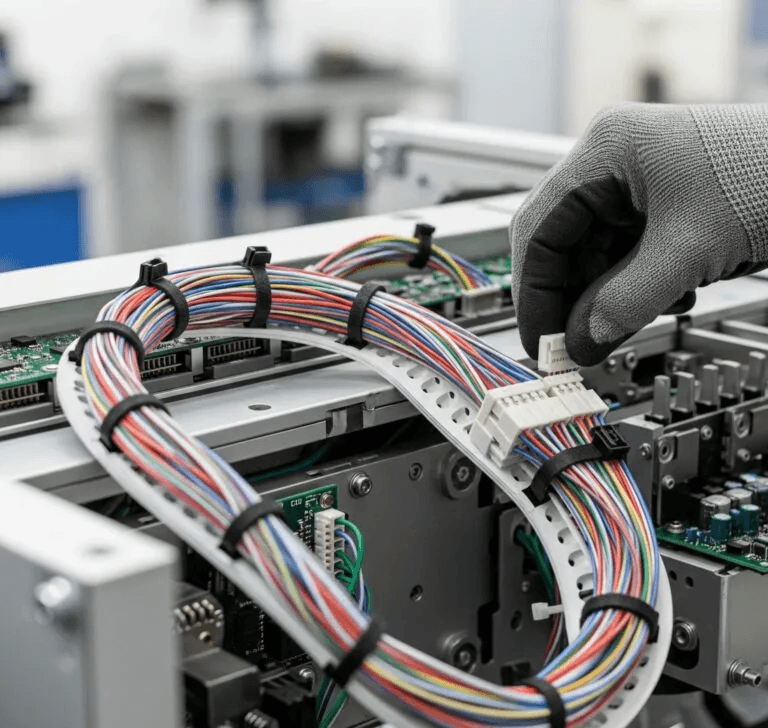

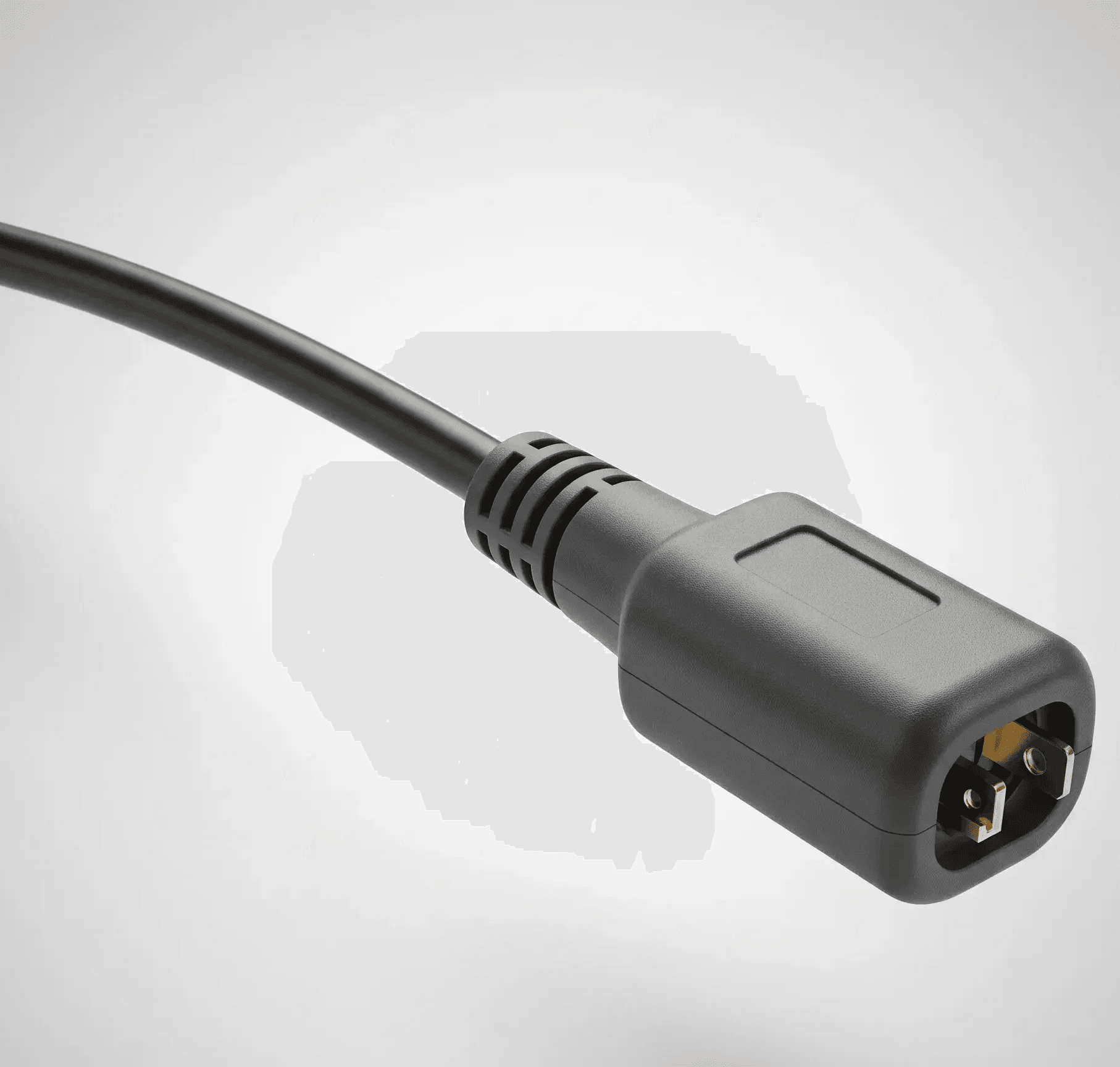

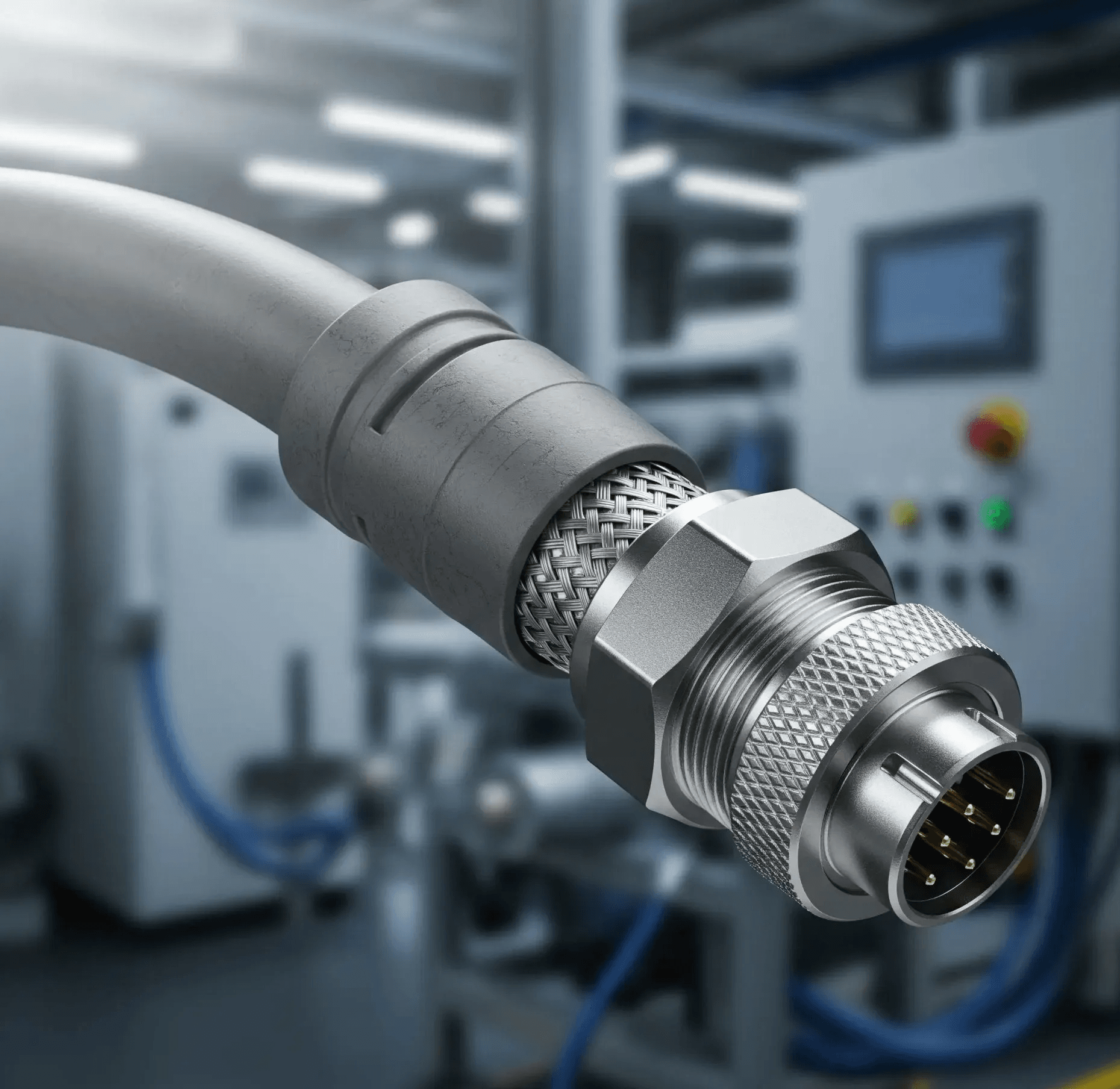

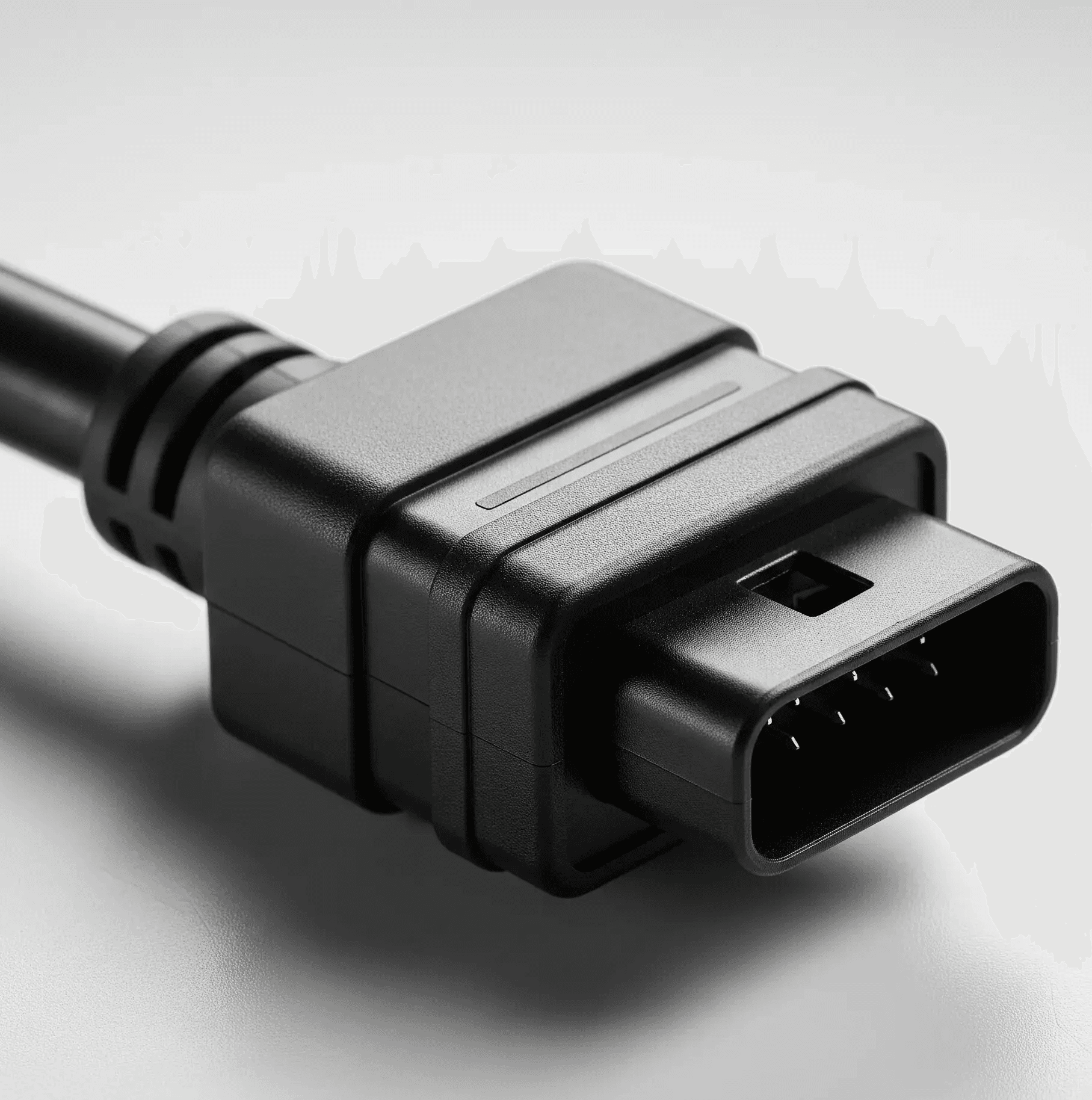

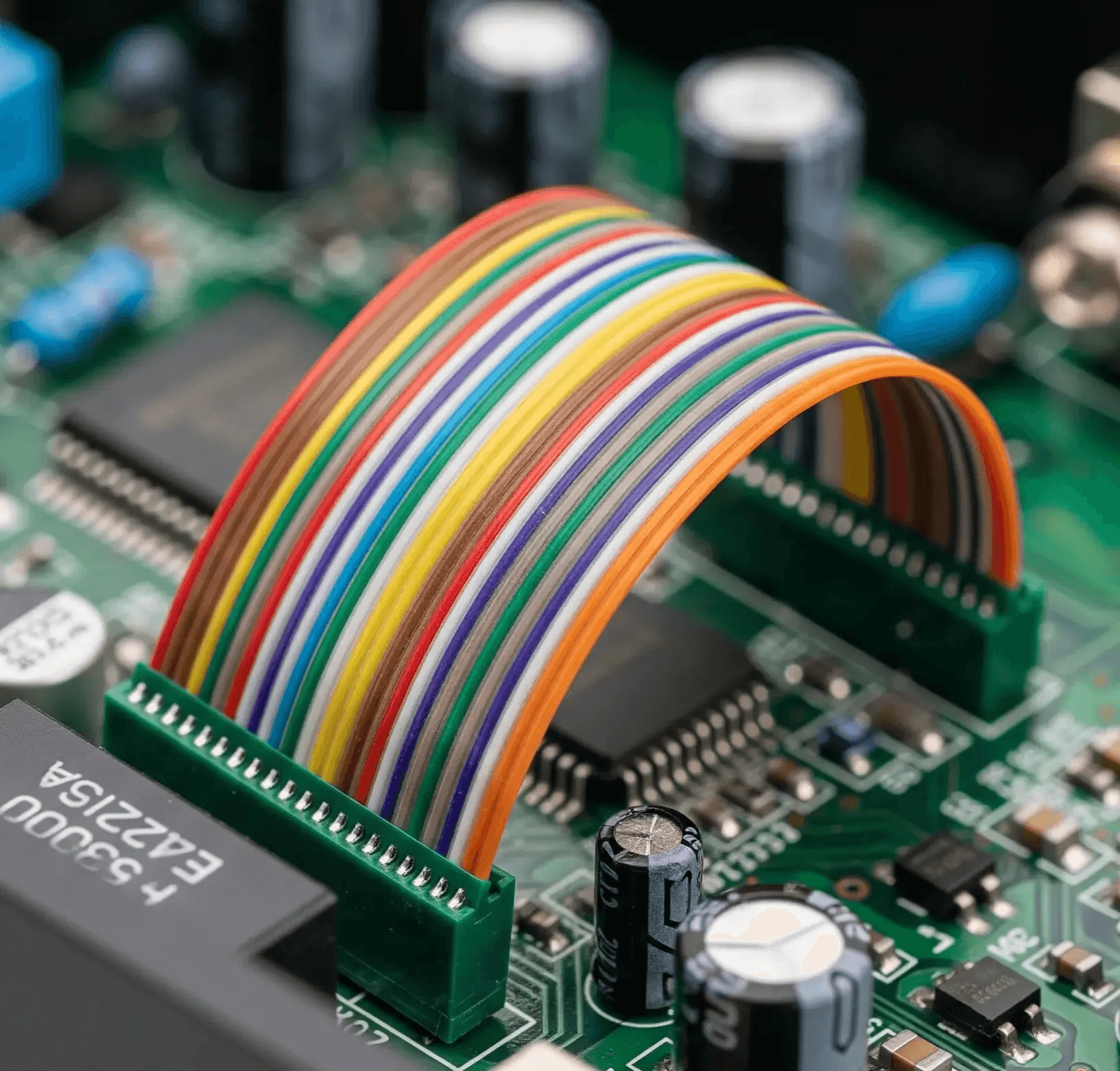

Custom Wiring Harness is a bundle of wires, cables, and connectors. These wires send power or data to different parts of a machine. The harness helps keep wires in order and makes machines easier to build and fix. Custom Wiring Harness keeps everything clean and easy to follow. They protect wires from heat, water, shaking, and damage. In heavy machines, they help workers fix problems fast. They also help make sure everything runs without problems. A good custom wire harness is made to last. It is easy to install and fits just right. This saves space and makes the machine run smoothly. A custom harness also makes fixing things later easier, saving time and money.