Ensure Custom Wire Harnesses Quality: Vital Testing Methods

By hdhhd shhsbbs / 2025年8月19日

Testing custom wire harnesses is a vital part to ensure the quality. With this process you can find out how reliable the harness materials are. With testing you can find out the issues and prevent them before it gets bigger. With it you can be sure to use it for various tasks daily.

If the wires are tested then the power supply will be smooth when you use it. It’s vital to check each connection before you use them. The testing process also ensures that the harnesses are ready for rough use. Each test is essential to confirm that the harnesses are ready for every kind of weather. If the testing is skipped then the harness will cost you money and time later.

Ensuring Custom Wire Harnesses Quality

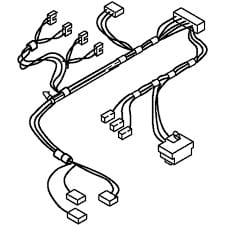

Mazos de cables personalizados are key parts in many tools we use each day. They safely move power, signals, and data from one spot to another. A harness is a group of wires tied into one bundle so they do not tangle or break. You can see them in cars, planes, hospital machines, robots, and home tools like washing machines. Without harnesses, wires would hang loose, be hard to fix, and cause danger.

When a harness fails, a car may stop, a robot may not move, or even a fire could start. This is why testing is a must. Each wire harness manufacturing company checks every harness to keep users safe, save money, and build trust. Testing shows proof that a harness will work even in hard times.

Why Testing Matters in Custom Wire Harness Making

Mazo de cables personalizado manufacturers make parts that must stay strong for many years. These harnesses face heat, cold, rain, dust, and shaking. Without tests, wires might snap, joints might get loose, or sparks might fly. These risks can stop a car, break a machine, or hurt people. To prevent this, a good wire harness supplier runs many tests. They check each part individually to see if it is tough and safe. These tests show that the harness can do complex jobs. Without tests, even the best plan can fail. Testing is always the top step in making wire harnesses.

Visual Inspection: First Step of Quality

The first test is looking with the eyes. This is called a visual check. Skilled staff look at the harness very closely. They search for broken wires, weak joints, loose tips, or bent ends. They also look for cuts on the cover. This test is fast but saves a lot of time later. It stops weak harnesses from going to the next step. Finding a fault early can save cost and work. Every custom wiring harness manufacturer does this test because it is simple but powerful.

Continuity Testing: Ensuring Proper Flow

The next test is a flow check. This test is called the continuity test. A small current is sent through each wire. If the wire is fine, the power flows from one end to the other. If the wire is cut or weak, the tester shows a fault. This helps workers fix the problem fast. Without this test, a harness may look fine but fail later. This test is small but key for safety, and it is used by custom automotive wire harness manufacturers to keep cars and trucks safe.

High Voltage Testing: Verifying Safety

Another test is high voltage, also called “hipot”. In this test, strong power is sent through the harness. If the wires and covers are tough, they hold up well. If they are weak, they fail right away. This test shows if the harness can face tough times. Cars, planes, and big machines need this kind of check. A custom wire harness manufacturer uses this to prove their harness can withstand strong use.

Pull Testing: Checking Mechanical Strength

Harnesses are often pulled and pushed. To test this, factories use pull checks. Machines grab the wire and pull till it breaks or comes out. This shows how strong the joint is. Weak joints are unsafe, especially in cars or planes that shake often. Pull tests show if joints can hold. A good custom wire harness manufacturing plan always has pull tests to ensure parts last.

Environmental Stress Testing

Some harnesses must face hard places. They may work in hot deserts, freezing snow, or near salty sea water. To test this, plants use stress boxes. These boxes make fake weather inside. They can be hot, cold, wet, or dusty. The harness is tested for long hours or days. If it works fine after this, it is ready. If not, the plan must change. This test is key for ship, plane, or outdoor harnesses. China custom wire harness makers use this to show their parts can last.

Signal Integrity Testing

Some harnesses carry data, not just power. In phones, PCs, and medical tools, signals must be clean. If the signal is weak, the tool may fail. Signal integrity checks make sure the data is precise. This test checks if the harness keeps the signal safe. It is key in telecom, innovative tools, and health gear. Custom harness suppliers know insufficient data can cause a significant loss. This is why they do this test with care.

Flex and Bend Testing

Wires bend a lot. Wires inside bend each time. To test this, plants use flex tools. These bend the harness back and forth many times. If the harness still works after this, it is strong. If not, it fails. This test shows if a harness can last for years. For mazo de cables personalizado automotive jobs, this is a must. It keeps wires in cars safe.

Resistance Testing: Checking Efficiency

All wires have some block, but too much is bad. High block makes heat and wastes power. This can harm tools. Resistance tests check this. They show whether wires are stron

First-rate Custom Wire Harnesses that has Overcome Tests

Some jobs need wires that can withstand rain or snow. Outdoor lights, farm tools, and cars often touch water. The Overmolded cables are made for this. It has seals that block water and dust. It works in rain, snow, and mud. It keeps wires inside dry and safe. This cable is strong and secure. Many wire harness manufacturers pick it for outdoor jobs.

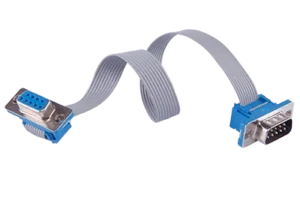

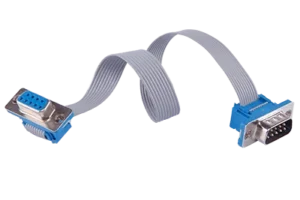

Sensors read speed, heat, or air. They must send this data safely. The Flat Ribbon Cables are made for that. It is strong, soft, and blocks noise. It can bend many times with no break. This keeps the data safe and clean. Robots, cars, and innovative tools use them. Custom wire harness automotive workers help cars read data without fault.

The Custom OBDII is best for data. It has a core wire, shield, and cover. The shield blocks noise, so data stays clean. With this cable, the video is sharp and the sound is clear. It is used in TV, cams, telecom, and guard systems. Each custom wiring harness manufacturer uses it when precise data is key.

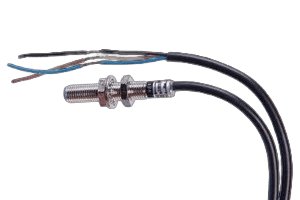

The sensor plug cable is like the sensor cable but has a plug. This makes it fast to use. A weak plug can cause insufficient data, but a strong plug keeps it safe. These are best for robots, health tools, and intelligent machines. They save time and are safe. A good custom harness supplier will always give them for quick work.

Choosing the Right Custom Wire Harness Supplier

Not all makers are the same. Some test well, some do not. A good maker gives safe, tested parts. A bad one may skip steps to save cost. That is why choice matters. A trusted custom wire harness supplier gives test notes, has proof, and has certs. They provide fast help and clear info. They use strict tests. This makes sure your parts are safe.

Common Tests vs. Benefits

Test Method | Benefit |

| Visual Inspection | Finds cuts and faults fast |

| Continuity Testing | Checks smooth power flow |

| High Voltage Testing | Proves the wires and cover strength |

| Pull Testing | Shows joint strength |

| Environmental Testing | Checks wires in hot, cold, or wet environments |

| Signal Integrity Test | Keeps data clear and safe |

| Flex/Bend Testing | Shows wires can bend many times |

| Resistance Testing | Finds weak wires and saves power |

QL-Custom Technology Ltd.: Your Trusted Partner

QL-Custom Technology Ltd. is a smart pick if you want the best China custom wire harness maker. They are a top custom wiring harness manufacturer with years of skill. They test all harnesses with care. They make cables that are best for the electric system. They also give support with fast help and good tips. Many trust them for long-term work because they have the tools, skills, and care to provide the best.

Testing makes harnesses safe and strong. It shows if they last in cars, planes, and tools. Without tests, even good parts can fail. Each test, from eye check to stress box, adds safety. Good tests give a long life. QL-Custom Technology Ltd. is a wise choice if you want safe harnesses and cables. They are a trusted custom wire harness manufacturer with skill and care.

Preguntas frecuentes

Do all harnesses get tested?

Yes, they should. Each harness is tested before it is sent out. This way, no harness leaves the factory unless it is safe and ready to use.

Who runs the tests?

Trained workers run the tests using special tools. They follow clear rules so the tests are fair and proper. Their job is to make sure every harness is safe.

Does testing take long?

No, most tests are quick. Even if they do not take long, they are essential. A short test can save you from big problems later.

How about an insulation test?

An insulation test looks at the wire cover. It checks if the cover stops sparks, shocks, and leaks. If the cover is good, the wires are safe. If it is weak, wires can touch and cause danger. This test keeps people and tools safe.

What is a hi-pot test?

A hi-pot test uses high voltage to see if wires can handle high power. If the wire passes, it is safe for heavy loads. If not, it is unsafe. This test shows how strong the wire really is.

La gente también pregunta

What is a spark test?

A spark test checks if wires leak power. Leaks can cause sparks, and sparks are unsafe. This test helps find bad spots before they cause harm.

How is heat tested?

The wires are put in a hot place to see if they last. Good wires stay in shape. Bad ones melt or lose power. Heat tests are key for safe use.

What is a cold test?

Wires are put in a cold place to check if they bend and work. Good wires stay soft and safe. Bad ones can crack or stop.

Can water be tested?

Yes, wires can be tested with water. Good wires stay safe and keep working when wet. Bad ones may spark or fail.

Why check plugs?

Plugs must stay tight. Loose plugs can fall out or lose power. Strong plugs make the harness last longer.

What is a life test?

A life test runs the harness for a long time. It shows how long it will last before it wears out. This gives a clear idea of lifespan.

Can the test find weak spots?

Yes, tests show weak areas in the harness. You can fix them early before they get worse. This keeps the harness safe.

Are all tests needed?

No, not every time. Big projects may need many tests. Small jobs may need only a few. The test depends on the need.

Can I test at home?

Yes, small tests can be done at home. A meter and a light can help. You don’t always need a lab for small projects.

Who does big tests?

Big tests are done by labs or skilled groups. They use machines to test deeply. They check safety in detail.

Custom Wire Harnesses With Diagram