製品紹介

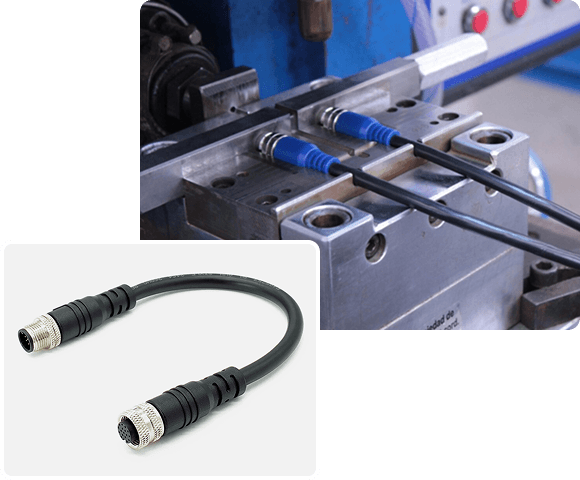

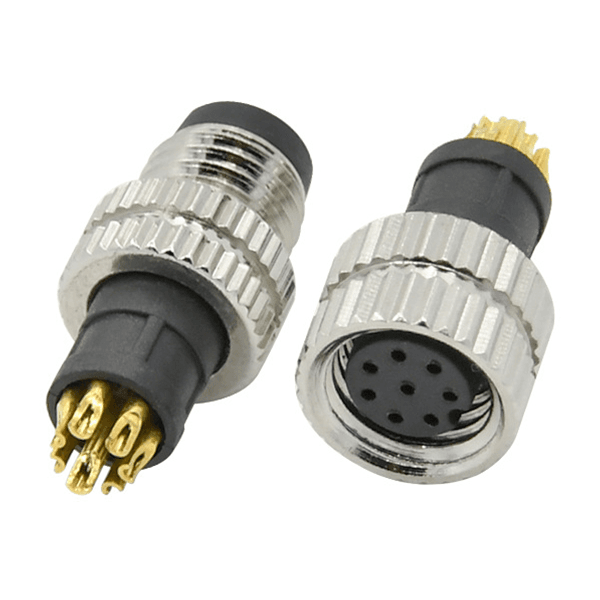

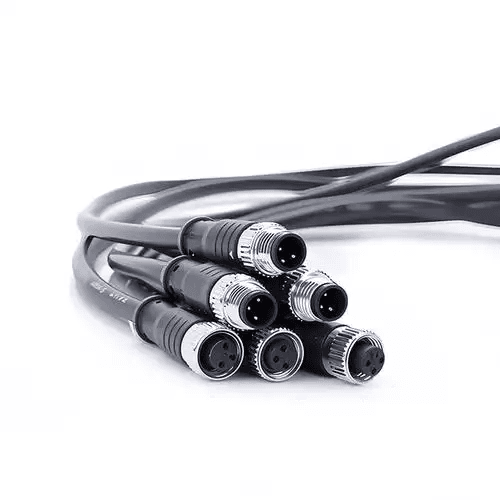

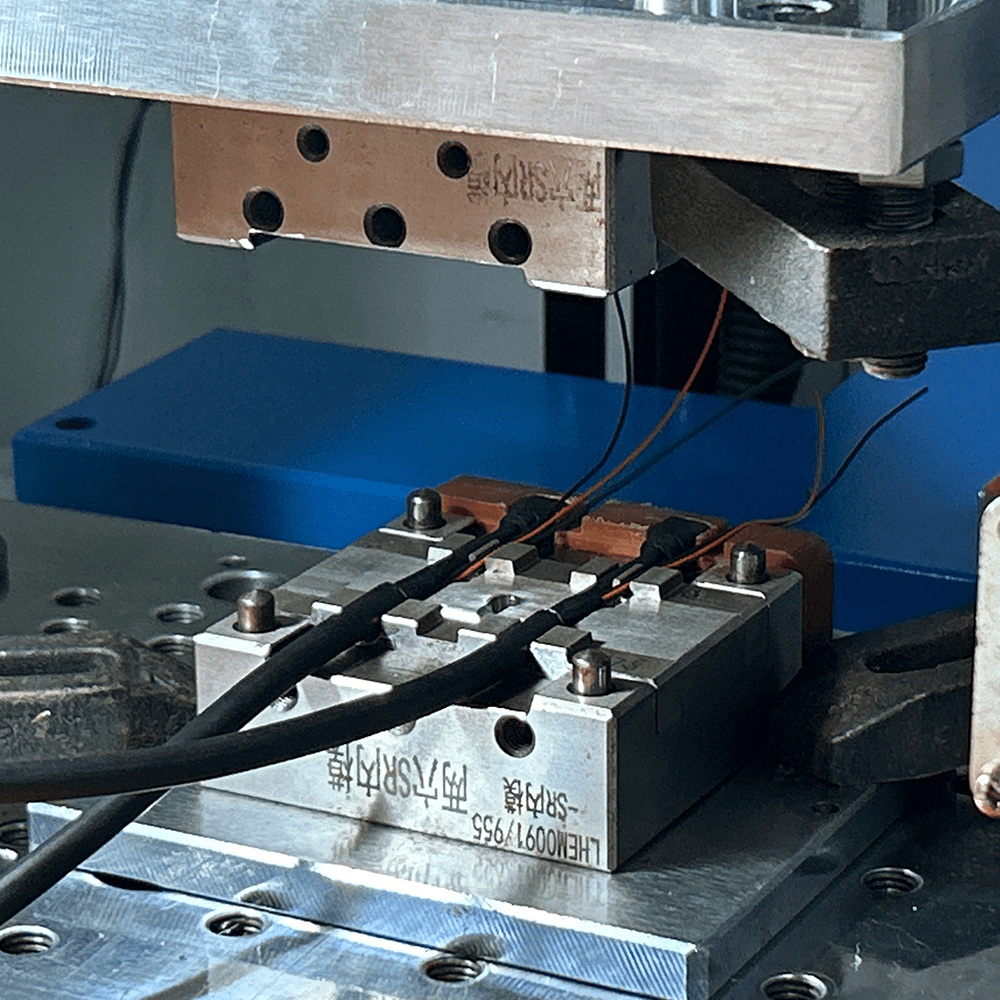

M12 round connectors are plugs that have four or five pins. It has a rounded shape. To connect wires, machines, or tools, you can use them easily. Overmolded cable assemblies are used for many sectors to supply power and signals. These cables and the plugs should be able to resist rust and dirt to work properly. Plastic overmolding is the best and exact process we use to connect the cables perfectly. The hot plastic perfectly keeps the connector inside in this step. For exact bonding, this process is necessary. The plastic completely takes the pressure of the core cable and keeps it safe from tough uses. There is a tool that keeps the connector in the same place when the mold is filled with plastic. After it cools down, it is fully sealed. This process is vital for the cable to work in tough situations.