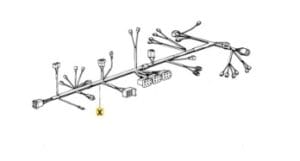

Custom Wire Harness for Complex Industrial Equipment

By hdhhd shhsbbs / 2025年8月25日

There are reliable parts that are essential for the best performances in the industrial equipment. A custom wire harness is the best way to keep the machine in a great shape. This harness ensures that the machine gets the exact power and signal. For smooth signal and power this harness plays a vital role in the equipment. Each harness is made with proper care to fit the machine perfectly. With a custom made harness you do not need to change the harness every time it saves you both time and money.

Power in Every Connection

Custom wire harnesses are essential for large and small machines that need power and data to work correctly. They combine power and data in one safe bundle so the machine can run smoothly and powerfully. A custom made wiring harness makes hard work safer and easier because it is made for one machine and not for all. These harnesses last much longer than loose wires that can break quickly. Each wire is cut, shaped, and built with care so no energy is lost and no part is weak. These harnesses help machines work in heat, cold, wet areas, and dusty places without failing. They give peace of mind that the job will be done safely.

Choose a Custom Made Wiring Harness

- Custom wire harness saves a lot of time during setup and repair work.

- Lowers the risk of mistakes, shorts, or loose links.

- Keeps all wires neat, tight, and safe at all times.

- Makes machines last longer and work with fewer problems.

- Helps workers feel safer and more secure during jobs.

- Gives more value because it is made for the exact job.

A wiring harness custom made is better than wires that are made to fit many things. It is made to match the real system, so it works with no gaps. It can take heat, dirt, stress, and heavy work without fail. A custom wiring harness for trucks or cars saves money, saves time, and keeps the gear safe and sound. This is why many brands and shops now use them for all gear.

Most Advanced Quality Custom Wire Harnesses

Custom XLR cable: for Media Systems

A Kundenspezifisches XLR-Kabel is excellent for sound gear and music systems. It gives clear sound with no hiss or noise. It is strong, shielded, and built to last long. These cables are used in concerts, music halls, live shows, and studios where sound must be perfect with no errors. A custom wire harness supplier like QL-Custom Technology Ltd. makes them in the right length and design to fit your needs well. They are not just for pro music users but also help home users get good sound in small systems. This cable makes music clearer and fun for all.

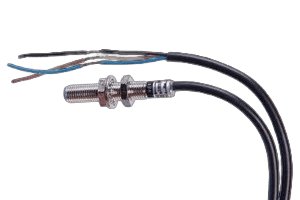

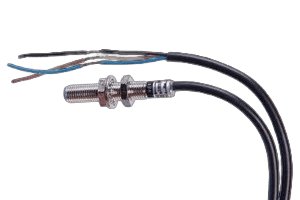

Sensor cable: for Control

A sensor cable connects smart parts inside machines and cars. It reads heat, speed, and pressure and returns this data to the system’s brain. In trucks, a custom wiring harness for trucks with sensors helps find problems fast and fix them quick. These cables have strong covers to stop noise and signal loss, so the data is always correct. They are used in cars, labs, planes, ships, and shop tools. A custom wiring harness with sensors can make old machines smarter by adding new data lines. This makes the machine safer, faster, and easier to run.

Overmolded cables: for Tough Jobs

Ummantelte Kabel are made for rough and rugged sites where dirt, water, and oil can harm wires. They have thick seals that protect the wires inside from dust, water, and heat. A custom automotive wiring harness with overmold makes cars and trucks last longer, even in mud, snow, heat, and rain. The mold holds wires tightly and gives a firm grip that will not break. These are best for farms, mines, ships, and factories where wires face harsh use. A wiring harness custom-made with overmold also looks neat, clean, and is simple to install.

Custom OBDII: for Smart System

A custom OBDII harness is used in cars and trucks for checks. It links the car computer with scan tools so data can be read. With a custom car wiring harness, you can check engine data, find faults, and test the motor fast. It is necessary for auto shops, truck fleets, and home car users. The harness makes car checks safe, easy, and straightforward to read. A custom wiring harness for cars helps mechanics fix cars with less guesswork. QL-Custom builds OBDII harnesses for many car makes, so users can get the right fit.

How Custom Engine Harness Helps

A Kundenspezifische Motorkabelbäume helps the engine work smoothly and safely. It gives power to spark plugs, fuel lines, and sensors at the right time. A custom engine harness is made for each car or truck type, not one-size-fits-all, so it fits right. It helps boost power, save fuel, and protect the motor from harm. These harnesses are used in race cars, farm gear, trucks, and work tools. A custom wiring harness for cars gives drivers peace of mind that the engine will run right every time.

Custom Wire Harness: Types and Uses

| Gurtzeug Typ | Beste Verwendung | Hauptmerkmal | Extra Note |

| Custom XLR Cable | Sound gear | Clear sound | Used in pro shows and homes |

| Sensorkabel | Smart tools | Strong signal | For labs, trucks, and machines |

| Overmolded Cable | Tough sites | Tight seal | Safe from oil, dust, and water |

| OBDII Harness | Cars, trucks | Scan tool link | Finds engine problems fast |

| Custom Engine Harness | Engines | Boosts power | Saves fuel and adds long life |

Get Quality Custom Wire Harness Easily

If you are searching for a custom wire harness, QL-Custom Technology Ltd. is a brand you can trust for safe and strong harnesses. They make custom wiring harness for cars and trucks with care and complete tests to make sure they last. They also build commercial custom harnesses for gear like planes, ships, and factory tools. Each harness is checked for safety, fit, and a firm hold. Visit their website and order your own harness that fits your needs. QL-Custom is a kundenspezifischer Kabelbaum supplier that ships worldwide and gives full support.

For safe, strong, and long-lasting custom wire harnesses, trust QL-Custom Technology Ltd. They build cars, trucks, labs, planes, and factory machines with complete tests. Visit their site today and order a harness constructed just for you, made to fit your needs, and made to last.

A strong wire harness is essential for safe work. It makes machines stronger, safer, and easier to use. Choosing a custom harness gives you a longer life, secure power, and smooth work. It also helps save money, lowers fire risk, and keeps workers safe.

FAQs

Can I get it made to my design?

You can ask makers to build a harness matching your design and needs. They can change the wires’ length, shape, color, and layout to fit your machine. If your machine is small or large, the harness can be built just for it. This ensures the harness is not too large or too small and does the job best. You get a harness made only for you that works without waste.

Is it safe for heavy use?

A custom harness has strong wires, covers, and durable ties. It can handle heat, stress, vibration, and long work hours without breaking. The harness lasts and stays safe even if the place or job is rough. It is built for daily work in heavy machines and keeps people and machines safe while running.

How long does it last?

A harness can last for many years if it is made with high-quality materials and is cared for in the right way. The wires are wrapped and tied to stay safe from wear and damage. Since they are not left loose, they are less likely to break. With regular checks and care, the harness will keep working well for a long time.

Can it work in hot places?

Yes, these harnesses are designed to work in very hot and cold, dusty, or dirty places. They can survive tough spots like busy factories, outdoor work sites, and machines that get hot from long hours of use. The materials are chosen to handle extreme heat or cold, so the harness keeps working without stopping the machine.

Who makes these harnesses?

These harnesses are built by trained, skilled workers who know machines well. They take care to create each harness neatly, safely, and strongly. They use their skills to ensure the harness lasts long and keeps machines safe. Their hard work helps people trust the product for daily use.

Die Leute fragen auch

What is a custom wire harness for industry use?

A custom wire harness is a group of many wires tied and placed together as one neat set. It is made for one special machine and not for all. It carries power and signals correctly, so the machine can work well. It also makes wires neat, safe, and easier to use. In machines, this keeps all cables in order, so workers do not get lost in loose wires.

Why do factories need custom wire harnesses?

Factories need them because every machine is not the same. Each machine has a special size, design, and use. A custom harness is made to match that machine. This makes work safer and smoother for the workers. It also helps the machines run longer with less trouble and fewer stops. With this, the whole factory saves time and money.

How do custom wire harnesses help heavy machines?

They hold all wires in one safe place. They stop wires from getting cut, bent, or loose. This makes machines run smoothly without sudden stops. They also lower the chance of fire, power loss, or damage. Finding and fixing the correct wire is easier and faster when a repair is needed.

Can custom harnesses handle heat and stress?

Yes, they can. They are built with powerful covers and safe parts. They can handle heat, water, oil, and pressure. This means they last in hard places like hot factories, wet areas, or dusty sites. Workers trust them because they do not break fast even in tough work spots.

Who makes custom harnesses for machines?

Special companies like QL-Custom Technology Ltd. build them for each machine. They first study the machine type and then design the harness to match it. They use safe parts and test them step by step. These companies work with factory teams to ensure the harness fits well and does the job right.

Are custom harnesses costly?

Yes, they may cost more than simple wires. But they save money later. They last longer, need fewer repairs, and stop sudden machine breaks. This lowers the total cost for the factory in the long run. Many owners see them as a smart buy, not just an expense.

How do workers test custom harnesses?

They use tools to check the power flow in the wires. They also test for cuts, short cables, and loose ends. Each harness is tested before shipping to the factory. This way, the machine is safe once it starts to run with the harness.

Can harnesses be made fast for urgent needs?

Yes, some companies can build them quickly. They offer fast service and ship them fast when needed. This helps when a factory has a machine stop and needs parts quick to keep working without delay.

Do custom harnesses make machines safer?

Yes, they do. They reduce sparks, fire risks, and power loss. They also keep workers safe from shock. A strong harness gives peace of mind to the owners and workers.

Can old machines use new custom harnesses?

Yes, they can. New harnesses can be made for older machines, too. Companies can copy old designs or create new ones that fit. This helps old machines run better and last longer like new.

Custom Wire Harness and Diagram