Low pressure molding material and Services for electronics

By hdhhd shhsbbs / 2025年6月16日

Tiny parts in electronic tools, like wires and chips, are easily damaged. If they get wet or hit, they can break. If one part fails, the whole device may stop working. Low pressure molding materials helps protect these parts. This process uses soft, hot glue-like Low pressure molding materials that cover the parts gently. It fills the empty spaces, blocks out dirt and water, and strengthens parts. It is also fast and clean. QL-Custom Technology Ltd. offers complete molding services. They use strong and trusted Low pressure molding materials like Technomelt. They work on PCBs, USBs, LEDs, and even sensors. Their molding work is quick, safe, and looks great.

Low Pressure Molding Material: Protect Small Electronics

Niederdruckgießen is a soft and gentle way to cover and protect small electronic parts. It uses a special type of melted plastic. This plastic flows slowly and wraps around the small piece without pushing hard. It fills every little space, and then it cools down very fast. After it cools, it becomes hard and strong. This makes a shield around the part, keeping water, dirt, heat, and damage away.

This method works well for small, delicate items like LED lights, wires, chips, and sensors. Because low pressure and low heat are used, your tiny parts do not get broken or moved. The parts stay in place and look clean. Many companies like this process much better than glue, tape, or high-pressure methods. It is quicker, neater, and safer. Your parts look better and last longer.

Low pressure molding material: Technomelt hotmelt resins

At QL-Custom Technology Ltd., we use Technomelt hotmelt resin for our work. This is a top-quality material, a well-known company that makes safe and strong products. This resin is great because it melts easily and flows like syrup. It slowly wraps around each part and fills every space. When it cools, it turns into a firm plastic cover that holds tight and keeps things safe.

Technomelt is also kind to the planet. It is made from safe, natural stuff that does not harm the air or water. It does not have a foul smell and doesn’t make smoke. It also does not leave a mess behind. It cools down quickly in just a few seconds. This saves time, saves work, and saves money. It helps your product, your workers, and the Earth. That’s why we use it every day.

Low Pressure Molding in 3 Easy Steps

Straightforward 3-step process when using low pressure injection molding to protect your electronics. Here’s how we do it:

- Step 1: Put the part inside a mold. This mold is shaped just right to fit your part. It holds it still and safe.

- Step 2: Melt the resin and inject it. The soft plastic moves slowly into the mold and covers your part from all sides. It does this gently, so nothing breaks.

- Step 3: Let it cool down fast. In just a few seconds, the melted resin becomes hard. The mold opens, and now your part is strong, covered, and safe.

This whole process is clean and quick. It doesn’t need glue, it doesn’t leave waste, and it doesn’t take long. So many people choose low pressure injection molding to keep their parts working well.

Low-Pressure Molding Is a Much Smarter & Safer Way

Low pressure overmolding has helpful benefits, making it better than other older ways. Here’s why you should pick it:

- It is soft on tiny, breakable parts like small wires and chips.

- It doesn’t burn or melt the parts.

- It cools very quickly.

- It keeps out water, dirt, bumps, and other damage.

- It uses fewer Low pressure molding materials and less equipment.

- It gives your part a clean and professional look.

- It is safer for people working with it.

- It has fewer problems, so your parts are ready faster.

With this method, your electronics last longer and look better. It saves time and reduces stress.

Low Pressure Injection Molding Machines

There are innovative and modern machines to do low pressure injection molding. These machines heat the resin, melt it, and gently push it into the mold. Our machines use a special side-feed system. This helps keep the part safe while it’s being molded.

We can control the temperature and the speed carefully. That means every part is made just right every time. They all come out looking clean, smooth, and strong. These machines make our work easier and help us do a better job for you.

Things to Make Using Low-Pressure Molding Techniques

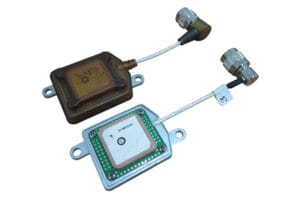

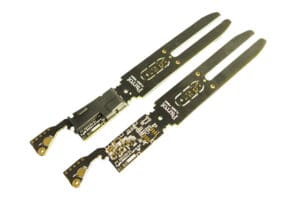

We use low pressure moulding to make many different electronic parts. These parts are small, soft, and need extra care. Here are some of the things we make and protect:

- Plugs for USB cables and power cords

- Covers for LED light parts

- Shells for sensors to keep them safe

- Tiny circuit boards (also called PCBs)

- Wire groups and cable ends

- Magnet coils and special winding parts

- Transducers and pressure-sensing parts

All these items need to stay clean, dry, and firm. Our process helps them do that.

Why Choose QL-Custom Technology Ltd.

At QL-Custom Technology Ltd., we care about your parts and your success. We work with you from the first step to the last. We make sure you get exactly what you need. Here’s what makes us a great partner:

- Friendly and helpful support.

- Unique design ideas and tips.

- We make special molds just for your parts.

- Many colors and types of resin to choose from.

- We test the parts to make sure they work well.

- Keeps everything clean and safe in our factory.

- We ship fast to anywhere in the world.

- Help you even after the work is done.

We’ve been doing low pressure overmoulding for over 25 years. No matter the size of your job, we’re here to help you make something great.

Low Pressure Molding to Keep Parts Safe

If your products use wires, boards, sensors, or other small parts, consider using low pressure overmoulding. It makes your parts last longer and keeps them safe from harm. They also look better and feel stronger. At QL-Custom Technology Ltd., we have the people, the tools, and the Low pressure molding materials to help you. We care about your needs and want your parts to work their best.

Send us a message or give us a call. Discuss how pressure molding and overmolding electronics connector parts can help your work. We’re happy to help you with any project.

QL-Custom Technology Ltd. – We make your electronics safer, cleaner, and stronger with easy and smart low-pressure overmolding.

FAQs

What is low pressure molding?

It is a way to cover small parts with soft plastic. The plastic is melted and flows around the part. Then it cools and makes a cover. This keeps out water, dust, and dirt.

Why use this kind of molding?

This molding is soft and safe. It does not hurt small parts. It is suitable for wires and boards. It makes things stronger and last longer.

Where is it used?

It is used on USB sticks, LED lights, tiny boards, and sensors. These things need protection but also must stay light and small.

What is PCB low pressure molding?

It covers the whole board with soft plastic. This blocks water and dirt from getting inside. It helps the board last longer.

What is Technomelt resin?

Technomelt is a soft glue that melts and covers parts. It sticks fast and cools quickly. It makes a strong seal.

Die Leute fragen auch

Why use Low pressure molding material?

This method keeps parts safe from water, dust, and bumps. It also makes things lighter and saves space. It is faster and cleaner than old methods like glue and complicated cases.

What is PCB low-pressure molding?

PCB low-pressure molding covers the small boards in devices. It keeps the board dry and safe. It helps the board last longer and work better.

What are Technomelt hotmelt resins?

These are special soft Low pressure molding materials used in low-pressure molding. They melt when warm and cool down into a safe, strong cover. They work well and do not harm the environment.

Is it safe for small parts?

Yes. The heat is low, so it won’t hurt the parts. It is perfect for sensors, boards, and tiny wires.

How long does molding take?

It’s swift. Many parts can be molded in just seconds. This helps save time when making and fixing devices.

Does it help stop damage?

Yes. It keeps out water, dust, and hits. It helps wires and parts last longer without breaking.

Where is this used?

It’s used in cars, phones, tools, and many gadgets. It is also great for robots and machines that must stay safe in wet or dirty places.

Can I use it at home?

It’s mostly for factories, but miniature versions are out there. If you fix a lot of gadgets, it might help you.

Is Low pressure molding material better than tape or glue?

Yes. It’s cleaner, safer, and lasts longer. It also looks better and keeps things more protected.

Can Low pressure molding material be used with all wires?

Most small wires and parts work well with Low pressure molding material. Just make sure the wire is safe for a bit of heat.