كيفية استخدام وصلة الأسلاك | وصلة الكابلات المخصصة

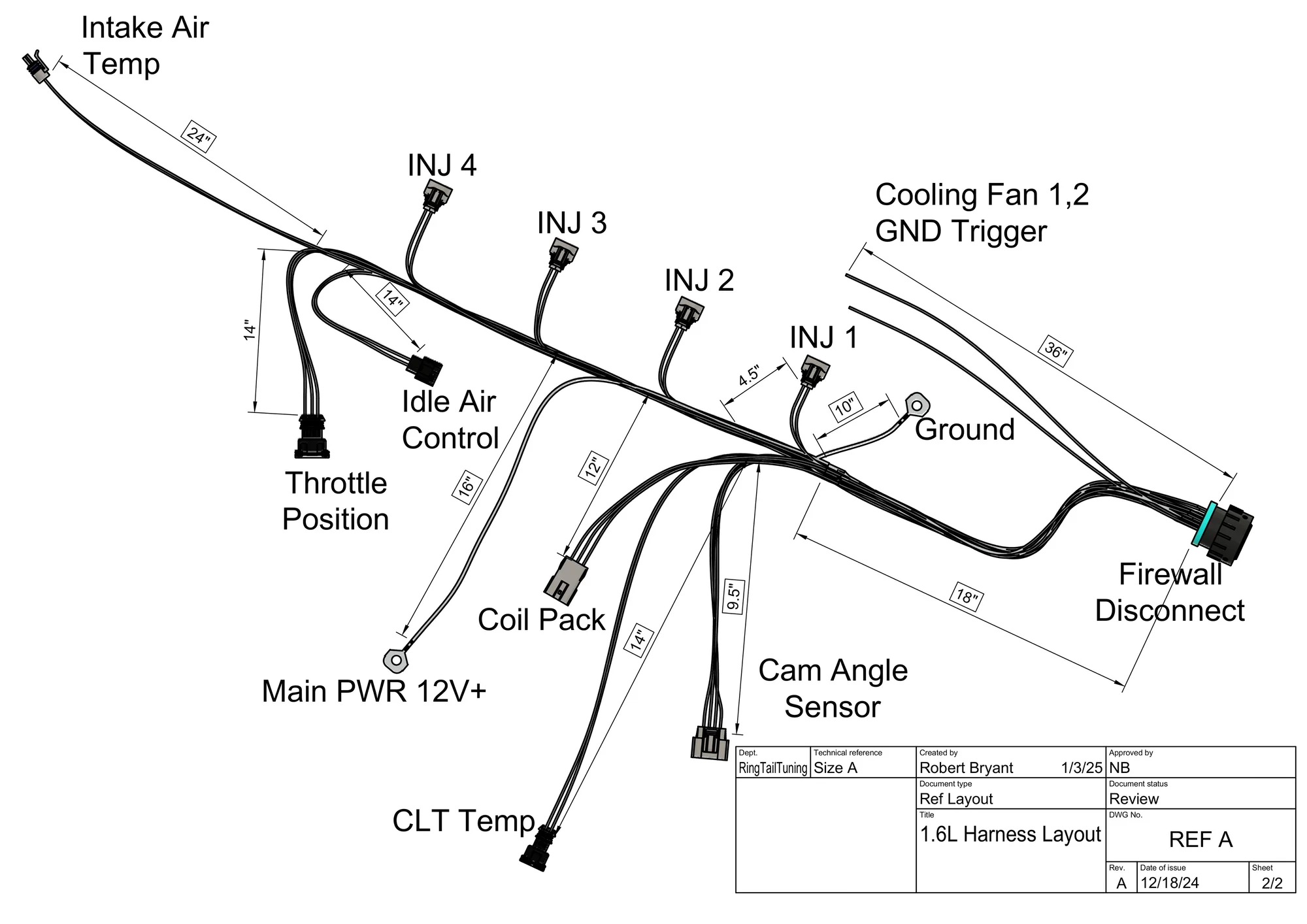

How to Use a Wiring Harness? Wiring harnesses or cables are crucial parts of contemporary electrical systems. They are pivotal in various industries, organizing, protecting, and streamlining electrical circuits. Whether you’re an engineer, technician, manufacturer, or hobbyist, understanding how to use a wiring harness effectively can improve your project's reliability, efficiency, and safety. These harnesses streamline complex wiring systems into an organized, easy-to-manage assembly, providing a structured and efficient power and signal distribution solution. This article will explore how to use a wiring harness, the advantages of custom cable harnesses, best practices for integrating them into your projects, and tips for selecting and implementing them in various projects. About Wiring Harness? Electrical cables or wires that carry signals or electricity are assembled in a wiring harness. Straps, cable ties, sleeves, or electrical tape secure these wires into a neat bundle. The harness may include connectors, terminals, and protective sheaths tailored to the application's needs. Instead of having a tangled mess of individual wires, a harness bundles them into a neat assembly, improving safety, performance, and installation efficiency. Several industries use wiring harnesses, including: Automotive Aerospace Industrial machinery Consumer electronics Telecommunications Medical equipment How to Use a Wiring Harness Using a wiring harness involves planning, installation, and testing. So you have to know the proper way to use it. For your better understanding, i will share here a step-by-step guide: Understand Your Requirements Start by reviewing your system's electrical schematics. Identify the number of connections, types of signals (power, data, ground), current loads, and environmental conditions. Key questions to ask: What voltage and current will be running through the harness? How many connectors or terminations are needed? Will it be exposed to water, oil, or extreme temperatures? Does the EMI protection of the harness require shielding? Choose or...

اقرأ المزيد "تسخير الأسلاك المخصصة الفائقة للوظيفة المناسبة

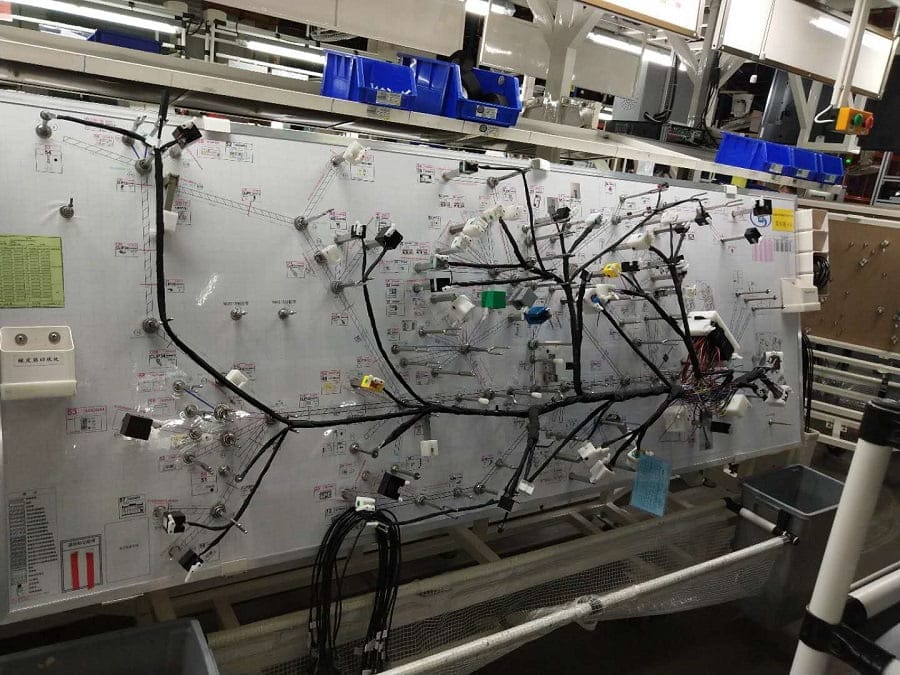

تربط مجموعة الأسلاك المخصصة أجزاء الماكينة مع الحفاظ على الأسلاك منظمة وآمنة. يضمن عمل المكونات الكهربائية بسلاسة. يمكن أن تكون الكابلات العادية فوضوية. فهي تتشابك وتنكسر بسهولة. يتم تصنيع الحزام المخصص لمهمة محددة. وهذا يساعد الماكينات على العمل بشكل أفضل ويدوم لفترة أطول. كما أنها تعزز السلامة، ولهذا السبب تعتمد عليها صناعات مثل السيارات والفضاء والآلات الثقيلة. تأتي أحزمة الأسلاك بأحجام وأطوال وأغطية مختلفة لإبقاء الأسلاك في مكانها بإحكام. وهذا يمنعها من الحركة أو التشابك. يساعد إبقاء الأسلاك مرتبة على تدفق الهواء بشكل أفضل. كما أنه يقلل من الحرارة. وهذا يجعل الآلات تعمل بسلاسة أكبر. تُستخدم أحزمة الأسلاك في المنازل والمصانع. فهي تحافظ على التوصيلات الكهربائية قوية وآمنة. يستخدمها المهندسون لتعزيز سلامة وصيانة الأنظمة الكهربائية. تقوم شركة QL-Custom Technology Ltd. بتصنيع أحزمة الأسلاك عالية الجودة. منتجاتنا آمنة وعالية الجودة. تثق بنا العديد من الصناعات. نقوم باختبار كل حزام للتأكد من أنه الأفضل. نبحث دائمًا عن طرق جديدة للتحسين. يعمل فريقنا مع العملاء لصنع المنتجات المناسبة لهم. أحزمتنا سهلة التركيب. تدوم لفترة طويلة وتعمل بشكل جيد. لماذا تختارنا لتصنيع أحزمة الأسلاك المخصصة؟ شركة QL-Custom Technology Ltd. حاصلة على شهادة ISO9001:2015. هذا الموقع خبير في تصنيع الأسلاك المخصصة. كما تقوم QL-Custom أيضًا بتصنيع مجموعات الكابلات المصبوبة بشكل مفرط. يتمتع فريقنا بسنوات عديدة من الخبرة. وتحظى منتجاتنا بثقة صناعات الإلكترونيات والطب والسيارات والروبوتات والجيش والطاقة النظيفة والكاميرات. يركز فريقنا على الابتكار والجودة وإسعاد العملاء. إذا كنت بحاجة إلى حزام سلكي مخصص، فاخترنا نحن! صنع أحزمة الأسلاك المخصصة: العمليات الفنية باستخدام آلات متقدمة وعمليات صارمة لمراقبة الجودة، ننتج أحزمة أسلاك مخصصة عالية الجودة. تستخدم ماكيناتنا الأتمتة لصنع الأجزاء بسرعة وبشكل صحيح. تعمل ماكينات EDM على تشكيل الأجزاء باستخدام...

اقرأ المزيد "