Maintenance and Troubleshooting

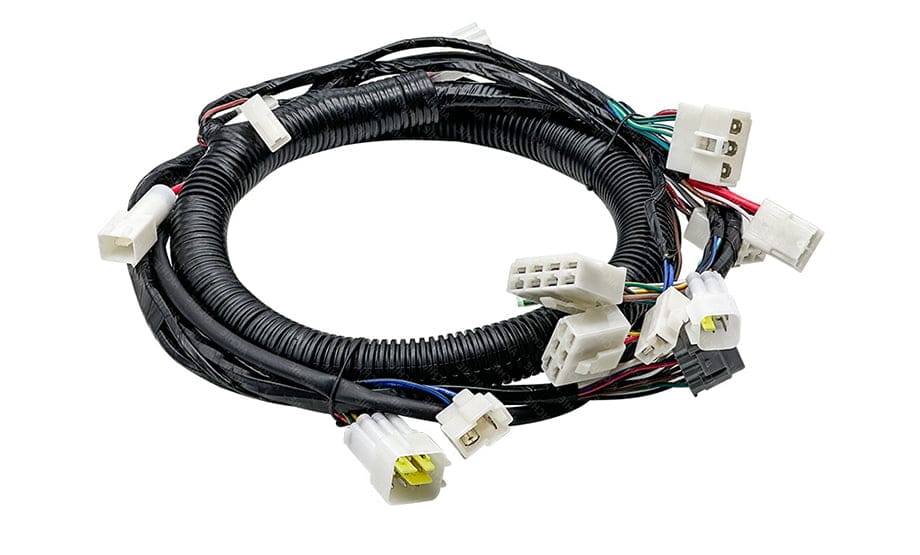

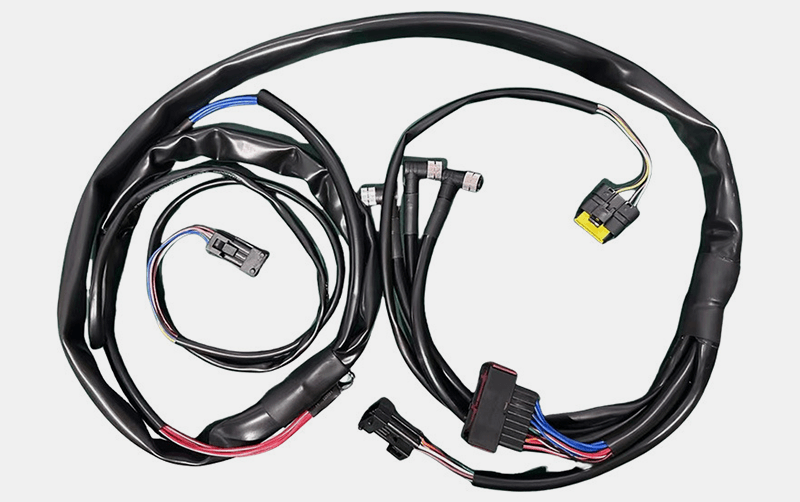

Proper maintenance of your truck or vehicle's wire harness is essential for smooth operation. Regular checks can prevent small issues from becoming big problems. Inspecting connectors, wires, and terminals helps you catch wear and tear early. Cleaning contacts and applying protective coatings can also prevent corrosion and signal loss. By taking these small steps, your wire harness lasts longer and works more efficiently.

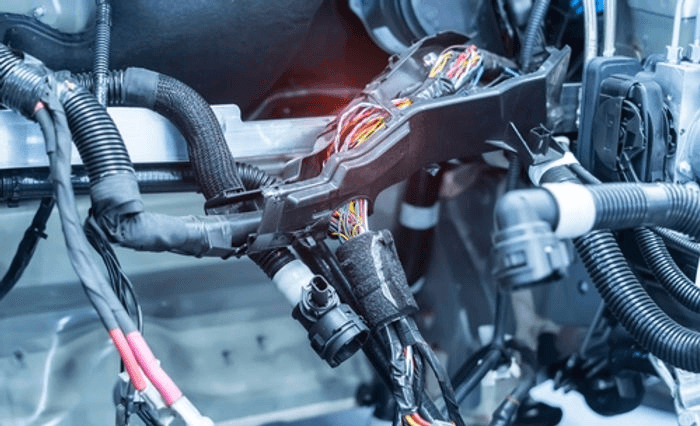

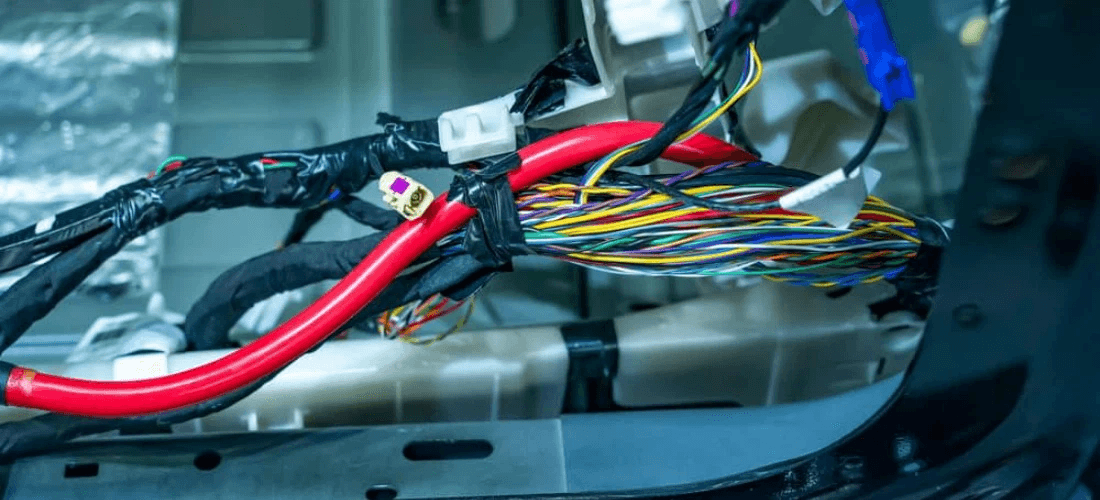

Troubleshooting is equally important when problems occur. If your lights, sensors, or other electrical components act strangely, it may be a sign of a loose connection or damaged wire. Using a systematic approach, technicians can identify the exact issue. They start by checking fuses, then inspect each wire for breaks, shorts, or corrosion. Modern diagnostic tools also help locate hidden faults quickly.

Our wire harness services are designed to make maintenance and troubleshooting easy. We provide expert guidance and high-quality replacements to ensure your system works reliably. By keeping your wire harness in top condition, you avoid downtime, save money, and ensure safety. Regular attention and prompt troubleshooting keep your truck’s electrical system running smoothly.