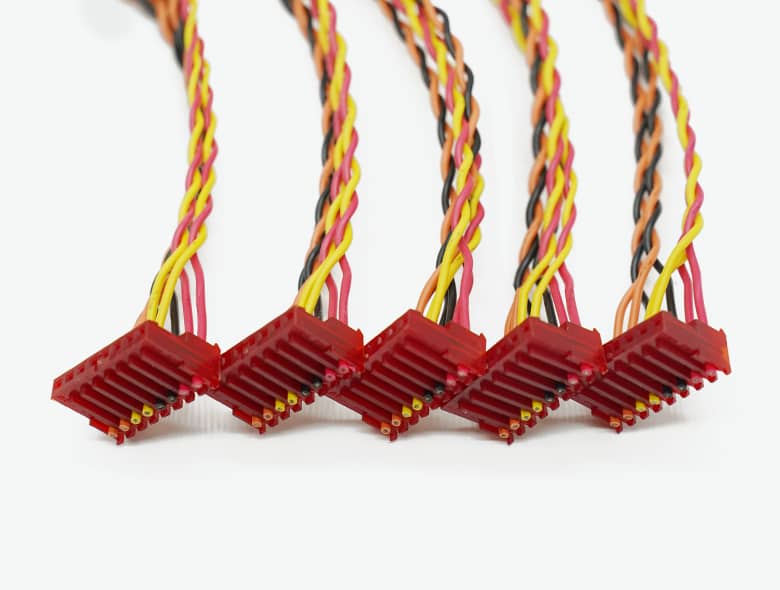

Cómo se fabrican los mazos de cables de automoción

Los coches tienen muchos componentes eléctricos. Las luces, las radios y los motores necesitan energía para funcionar. Un mazo de cables de automoción es un conjunto que ayuda a enviar la energía a los lugares correctos. El sistema eléctrico de un coche no funcionaría bien sin un mazo de cables. La fabricación de un mazo de cables comienza cortando los cables a la longitud correcta. A continuación, los cables se colocan en grupos para que no queden desordenados. Se añade una cubierta para proteger los cables del calor, el agua y los daños. Después, se prueba el mazo de cables para asegurarse de que funciona. Un buen mazo de cables ayuda a que los coches funcionen sin problemas y de forma segura. ¿Cómo diseñan los ingenieros un mazo de cables? Antes de fabricar un mazo de cables, los ingenieros tienen que planificarlo. Deciden dónde debe ir cada cable. Y se aseguran de que se conecta a las piezas correctas, como las luces, el motor o los sensores. Si se equivocan, el coche podría no funcionar. Los cables también tienen que ser seguros. Deben soportar el calor, las vibraciones y la humedad sin romperse. Un buen diseño ayuda a que el mazo de cables del coche dure mucho tiempo y mantenga el coche funcionando sin problemas. Elección de los materiales adecuados Un mazo de cables es un conjunto de cables. Estos cables llevan energía a diferentes partes del coche. Deben ser resistentes y seguros. Si se calientan demasiado o se rompen, pueden causar problemas. Una cubierta los protege del agua, la suciedad y el calor. Sin esta cubierta, los cables pueden fallar. Si eso ocurre, el coche puede no funcionar. Un buen mazo de cables evita incendios y cortocircuitos. Los materiales resistentes ayudan a que el coche funcione bien durante mucho tiempo. Cortar y pelar los cables Después de elegir los materiales adecuados, hay que cortar los cables al tamaño correcto. Si un cable es demasiado corto, no llegará a su parte. Si...

Leer Más "¿Los cables de seguimiento GPS DAB mejoran la seguridad del vehículo?

Mantener un coche seguro es muy importante para cualquier propietario. Los coches pueden ser robados muy rápidamente, y eso puede ser muy estresante. Sin embargo, con un cable de localización GPS OBD, los propietarios de automóviles siempre pueden saber dónde está su coche. Este pequeño cable se enchufa en el coche y se conecta a un sistema de localización GPS. El sistema envía señales a un teléfono o un ordenador. El propietario puede ver la ubicación exacta del coche en un mapa. Si le roban el coche, puede encontrarlo rápidamente. Por eso son tan útiles estos cables de seguimiento. Los ladrones saben que los coches con localización GPS son fáciles de encontrar, por lo que no quieren robarlos. Estos cables son pequeños, fáciles de instalar y no cuestan mucho. ¿Qué es un cable de seguimiento GPS OBD? Este cable es un cable pequeño pero beneficioso. Ayuda a que un rastreador GPS funcione dentro de su coche. Este cable se enchufa en el puerto OBD, una ranura única dentro de la mayoría de los coches. Todos los coches modernos tienen este puerto. El cable OBD da energía al rastreador GPS, por lo que no es necesario cargarlo o utilizar baterías adicionales. Configurarlo es muy sencillo. No necesita ninguna herramienta. No necesita un mecánico. Basta con conectarlo y empieza a funcionar de inmediato. Es una de las maneras más fáciles de rastrear un coche. ¿Cómo funciona el cable? El cable OBD conecta el rastreador GPS al sistema de su coche. Una vez enchufado, el rastreador se enciende. Comienza a enviar actualizaciones sobre la ubicación de su coche. Puede comprobar dónde se encuentra su vehículo en cualquier momento. Puede utilizar una aplicación o un sitio web en su teléfono, tableta u ordenador. Este sistema de seguimiento es útil de muchas maneras. Las familias pueden hacer un seguimiento de sus coches y...

Leer Más "Consideraciones de diseño para el moldeo por baja presión a medida

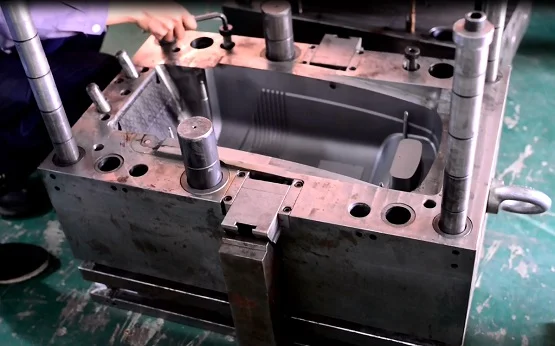

El moldeado a baja presión mantiene a salvo los componentes electrónicos. Los protege del polvo, el agua y los daños. Hace que las piezas sean fuertes y sólidas. No se agrietan ni se rompen con facilidad. También es una forma económica de sellar piezas delicadas. Para fabricar las piezas mejor moldeadas, hay que planificarlo bien. Piense en los materiales y el diseño. Piense también en la resistencia de las piezas. Elegir la mejor máquina de moldeo Una máquina de moldeo da forma a los materiales. Elegir la adecuada es muy importante. Debe ajustarse al tamaño, tipo y presión necesarios para el trabajo. Una buena máquina produce piezas fuertes, lisas y limpias. Una mala máquina puede producir piezas débiles, ásperas o rotas. La máquina debe ser fácil de usar. Si es demasiado difícil de controlar, pueden producirse errores. Una máquina sencilla ahorra tiempo y esfuerzo. Una buena máquina también consume menos energía. Esto ayuda a ahorrar dinero y a fabricar mejores piezas. Una máquina fuerte y bien construida dura más y necesita menos reparaciones. Elegir el material adecuado El material utilizado en el moldeo es vital. Algunos son blandos y otros duros. El moldeo a baja presión suele utilizar plásticos que se funden y fluyen con facilidad. El material adecuado hace que las piezas sean fuertes y duraderas. El incorrecto puede romperse o no pegarse bien. Algunos materiales se doblan con facilidad. Otros son rígidos y fuertes. Si una pieza debe soportar calor, necesita un material resistente al calor. Algunos materiales duran más que otros. Elegir el mejor material ayuda a fabricar productos mejores y más duraderos. Un sistema de moldes da forma a las piezas. Un sistema bien hecho se llena suavemente. Se enfría uniformemente. No desperdicia material. No atrapa aire. Las burbujas de aire pueden debilitar las piezas. Un buen sistema de moldeo produce piezas perfectas en todo momento. El molde también debe ser fácil de limpiar y arreglar....

Leer Más "Seleccione el mejor conector moldeado por inyección de plástico a medida

Un conector moldeado por inyección adecuado hace que todo funcione sin problemas. Uno malo puede causar grandes problemas. Puede hacer que se pierdan piezas, que se rompan conexiones o que las cosas dejen de funcionar. Elegir el adecuado ayuda a que los dispositivos duren más. También hace que funcionen mejor. Esta guía le ayudará. Aprenderá lo que debe buscar. Verá qué materiales son los mejores. Sabrá cómo hacer una buena elección. Moldeo por inyección para un conector moldeado El moldeo por inyección es la mejor forma de fabricar conectores de plástico moldeados por inyección a medida. En primer lugar, el plástico se calienta hasta que se funde en un líquido. A continuación, este plástico fundido se introduce en un molde. El molde le da la forma adecuada. Después, el plástico se enfría y se endurece. Una vez sólido, el conector está listo para su uso. Este método se utiliza para fabricar conectores fuertes y exactos. Muchas industrias utilizan el moldeo por inyección. Las empresas automovilísticas lo utilizan para los conectores del interior de los coches. Las empresas de electrónica lo utilizan para conectores. Las empresas médicas lo utilizan para conectores especiales. Por qué utilizar el moldeo por inyección de plástico en los conectores El moldeo por inyección de plástico es muy popular. Es rápido y asequible. Permite fabricar muchos conectores de alta calidad a la vez. Después de hacer un molde, se pueden producir miles de conectores idénticos rápidamente. Como las máquinas hacen la mayor parte del trabajo, hay menos errores. Esto significa menos plástico desperdiciado, lo que ahorra dinero. Otra razón por la que la gente lo utiliza es porque permite diseños muy detallados. Esto es útil cuando se fabrican conectores pequeños o complejos. El proceso también es muy fiable. Los conectores salen siempre iguales, por lo que encajan bien y duran mucho. Elija el molde de plástico adecuado para los conectores Un molde de plástico da forma al plástico. Elegir el molde adecuado es muy importante para un conector. Un molde debe ser resistente...

Leer Más "Aplicaciones comunes de un mazo de cables personalizado

Los cables pueden ser un lío. Pueden enredarse. Pueden romperse. Un arnés de cables a medida los mantiene a salvo. Los mantiene unidos. Detiene los daños. Ayuda en muchos lugares. Los coches los usan. Los aviones. Las fábricas. Incluso en los hospitales. Hacen que las cosas funcionen mejor. En esta guía aprenderemos dónde se utilizan. Veremos por qué son tan útiles. ¿Qué es un mazo de cables a medida? ¿Es vital? Estos cables transportan energía. Están atados juntos para mantenerse ordenados. Esto mantiene las cosas seguras. Ayuda a que las máquinas funcionen bien. Hace que las máquinas duren más. Sin mazos de cables, los cables estarían desordenados. Podrían romperse. Esto causaría grandes problemas. Las máquinas dejarían de funcionar. Sería difícil repararlas. Muchas industrias utilizan mazos de cables para evitar estos problemas. Ayudan a que las máquinas funcionen mejor. Hacen que las cosas sean más seguras. Un mazo de cables es como los nervios del cuerpo. Lleva la energía allí donde se necesita. Hace que las cosas funcionen bien. Protege los cables. Ayuda a las máquinas a durar. Sin él, las máquinas se romperían a menudo. Arreglarlas sería difícil. Por eso los mazos de cables son esenciales. Los mazos de cables son lo mejor para los vehículos Un mazo de cables de motor ayuda a que el motor arranque y funcione. Sin mazos de cables para motor, los cables podrían enredarse. Esto podría ser inseguro. Los mazos de cables también ayudan con la seguridad. Conectan airbags, GPS y cámaras de marcha atrás. Los coches eléctricos los necesitan para conectar la batería al motor. Esto permite que el coche funcione bien. Sin ellos, los vehículos eléctricos no funcionarían. Los coches necesitan muchos cables. Estos cables alimentan las luces, las ventanillas y los cierres. Ayudan con la velocidad y los frenos. También muestran información esencial en el salpicadero. Un mazo de cables hace que todo funcione. Evita que los cables se suelten. Mantiene los coches seguros. Sin él, los coches...

Leer Más "¿Son los conectores OBD personalizados mejores que los puertos OBD estándar?

Los coches tienen puertos OBD. Estos puertos ayudan a detectar problemas. Los puertos estándar no siempre encajan bien. Un ajuste flojo puede causar problemas. Puede hacer que la conexión sea débil. Puede dificultar las comprobaciones del coche. Los conectores OBD personalizados solucionan este problema. Se agarran mejor. Se conectan más rápido. Duran más. Facilitan las comprobaciones del coche. En esta guía, veremos cómo funcionan. Aprenderemos por qué pueden ser mejores para usted. ¿Qué es un conector DAB? Un conector OBD es un pequeño enchufe en un coche. Se conecta a una herramienta llamada escáner. Este escáner comprueba si el vehículo tiene algún problema. Si hay un problema, el escáner muestra un código. Este código ayuda al mecánico o al propietario del coche a saber cuál es el problema. Todos los coches tienen un puerto OBD. Sin él, encontrar los problemas del coche sería complejo. Llevaría más tiempo y esfuerzo solucionar los problemas. El sistema OBD controla el motor del coche, el combustible y otras partes. Si algo va mal, el conector OBD ayuda a encontrarlo rápidamente. Los propietarios de coches y los mecánicos utilizan escáneres OBD para leer los códigos. Esto facilita la reparación de los coches. Sin un puerto OBD, la gente tendría que comprobar cada pieza a mano. Esto llevaría más tiempo y costaría más dinero. Conectores OBD estándar vs. personalizados La mayoría de los coches tienen un puerto OBDII estándar. Este puerto es el mismo en todos los vehículos. Un simple escáner puede comprobar si hay problemas. Uno personalizado es diferente. Está hecho para necesidades especiales. Puede encajar mejor, trabajar más rápido, o tener características adicionales. Algunos coches necesitan un conector OBD personalizado para funcionar bien, pero la mayoría no. Si un vehículo tiene un ajuste único o sistemas adicionales, un conector personalizado puede ayudar. Un puerto OBD estándar comprueba problemas comunes, como problemas del motor. Se...

Leer Más "Instalar correctamente un nuevo mazo de cables de automoción

Un vehículo necesita un buen mazo de cables de automoción. Conecta las piezas esenciales. Asegura que la energía fluya correctamente. Si los cables no están en su lugar, el vehículo puede no arrancar. Las luces pueden no funcionar. Incluso podría ser inseguro. Cada cable tiene una función. Debe estar conectado. Un buen mazo de cables evita problemas. Evita cortocircuitos. Asegura que todas las piezas reciban corriente. También facilita las reparaciones. Instalarlo correctamente es esencial. Ayuda a prevenir accidentes y mantiene el coche funcionando bien. Reúna todas las herramientas y el kit de cables de automoción que necesite. También debe comprobar que su kit de cables de automoción tiene todas las piezas correctas. Haga una lista de todo para no olvidar nada. El trabajo será mucho más fácil y rápido si tienes todas las herramientas y piezas preparadas. Un espacio de trabajo bien organizado también te ayudará. Te ayudará a mantener todo en orden. También ayuda a evitar cualquier confusión durante la instalación. Desconecte siempre la batería del coche en primer lugar para estar seguro La seguridad es la parte más esencial del trabajo con los cables del coche. Si los cables no están desconectados, entonces podría dañar usted y su arnés de cables. Podría dañar los cables o incluso su coche entero. Quitar la batería asegura que no corra corriente por los cables mientras trabajas. Empieza quitando primero el terminal negativo y luego el positivo. Esto ayudará a detener cualquier problema eléctrico. Asegúrese de colocar la batería en un lugar seguro donde no cause ningún peligro mientras trabaja. Retire con cuidado el viejo mazo de cables de automoción Retire con cuidado el viejo mazo de cables de automoción. No tire demasiado fuerte porque podría dañar otras partes de su coche. Vaya despacio y sea paciente. Etiquete cada alambre como usted...

Leer Más "Is Low Pressure Molding Better for Sensitive Electronics

Low pressure molding covers delicate electronics like a soft shield. It keeps them safe from heat, dust, and damage. Some methods are too rough and break parts. Others do not protect enough. This method is just right. A unique material melts and flows over parts smoothly. It does not press too hard. When it cools, it forms a strong shell. This stops water, dirt, and damage. Many industries use this method. It helps electronics last a long time. Let's see why it is the best choice. Low Pressure Molding Keeps Tiny Parts Safe Small electronics are very delicate. They can break so quickly if not handled carefully. Low-pressure molding gently covers these tiny parts. It does not press too hard. Other molding methods use strong force. That force can damage circuits. When circuits break, the device stops working. Low-pressure molding applies a soft, even layer. It keeps everything safe. This method protects delicate devices. It helps them last longer. It keeps circuits, sensors, and chips from getting damaged. It is the best way to keep small parts safe. Uses Special Protective Materials Low-pressure molding uses unique protective materials. These materials are strong. They shield electronics from heat, water, dust, and dirt. Heat can cause electronics to overheat. Water can cause rust and short circuits. Dust can clog small parts. Dirt can make things stop working. The protective materials stop all these problems. They keep fragile parts safe. Even though the cover is challenging, it is gentle. It does not press too hard on the device. That makes it perfect for delicate electronics. It is excellent for medical tools. It is terrific for car sensors. It is great for factory machines. It protects electronics from harmful conditions. Low Pressure Injection molding Works With Smart Mold Systems New mold systems make low-pressure...

Leer Más "What Sectors Use Custom Plastic Injection Molded Connectors

Some things need unique Plastic Injection Molded Connectors to stay together. These pieces are made very carefully to fit just right. They are super strong and last a long time. Many places need these pieces so machines, tools, and other things can work correctly. These unique pieces make sure things don’t break and stay in place. Let’s look at all the areas that need them! Vehicles Need Plastic Injection Molded Connectors to Work Cars, trucks, and buses have lots and lots of little parts inside them! molded connectors help these big machines run. They help lights turn on, doors lock, and radios play music. These small plastic parts are super special! They are light, so cars do not have to work too hard. They do not get rusty, even when it rains or snows. That means cars last a long, long time! If cars did not have molded connectors, they would break faster and cost more to fix. These little plastic parts help cars be strong and safe! Hospitals use Plastic Injection Molded Connectors Doctors and nurses use special machines to help sick people get better. Molded connectors are inside these machines to help them work! They are in heart monitors, X-ray machines, and even tiny hearing aids. These pieces must be super strong and very clean. If they were dirty or broken, the machines would not work right! That would be bad for sick people. molded connectors help doctors and nurses save lives every day! Molded Connectors are Also In smart Gadgets Phones, TVs, computers, and video games all need molded connectors to work! These small parts help buttons turn on, and screens light up. Without them, headphones would not play music, and smartwatches would not tell time. These plastic parts also stop things from getting too hot and...

Leer Más "Utilice los conjuntos de cables de la forma mejor y más sencilla

Cable Assemblies help things work. But they need to be used correctly so they do not break. They will last longer and work better if you take care of them. There are simple steps to keep wires safe and strong. If cables are put in place correctly, they will not get damaged. Good wire care means things will work better for a long time. Pick the Very Best Cable Assemblies for What You Need Cables are like magic strings! They help things work! Some cables bring power, like the power that makes lights turn on, and computers work. Some cables move things, like pictures, sounds, and words! Every cable has an exceptional job! If you pick the wrong one, things will not work right. That is not fun at all! Picking the right one makes everything easy and happy! Look at how long the cable is! If the cable is too short, it will not reach where you need it! That is super frustrating! If the cable is too long, it can get all messy and tangled like a big spaghetti pile! You do not want to trip over messy wires! That is not safe! Pick strong Cable-Assemblies, too! Some Cable-Assemblies are robust and can fight heat, water, and bumps! That helps them last a long, long time! Check the ends of the cable! The wrong ends will not fit! That means you cannot plug them in! That is a big problem! Ensure the cable you pick has the proper ends so everything fits perfectly! A suitable cable makes everything easy, smooth, and happy! How to Keep Your Wires Neat and Nice Messy, tangled wires are not good at all! They twist and turn and get all jumbled up! That can make them break! And if they fail, nothing...

Leer Más "