Introduzione al prodotto

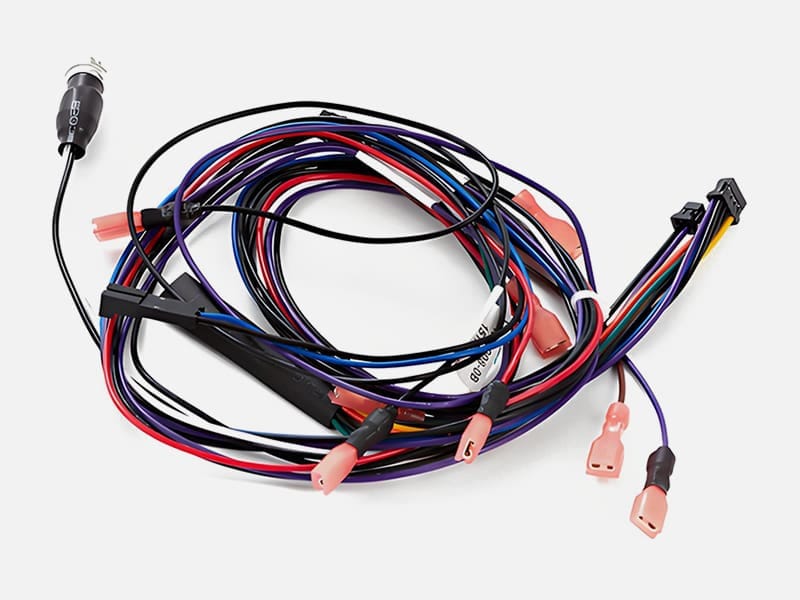

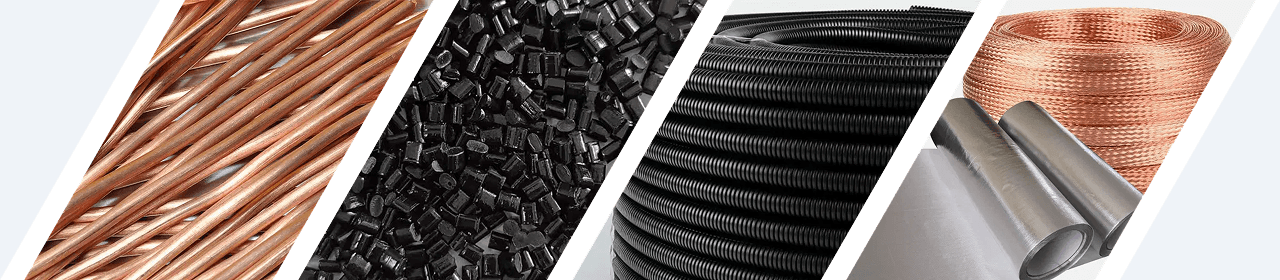

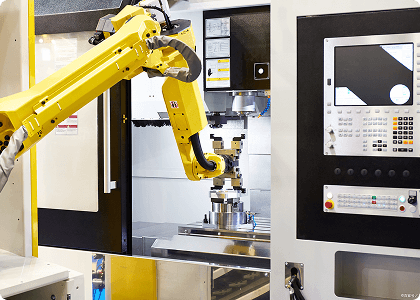

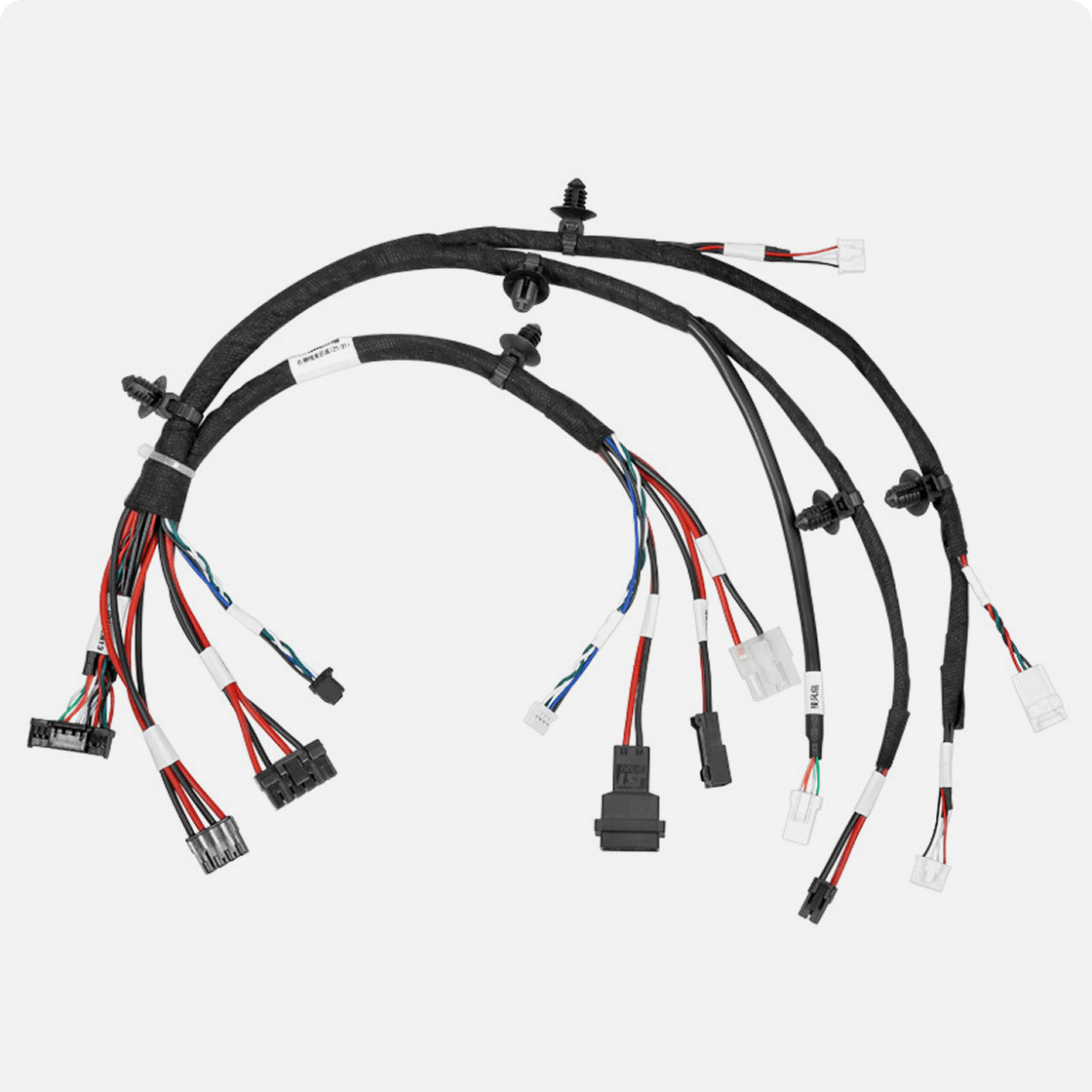

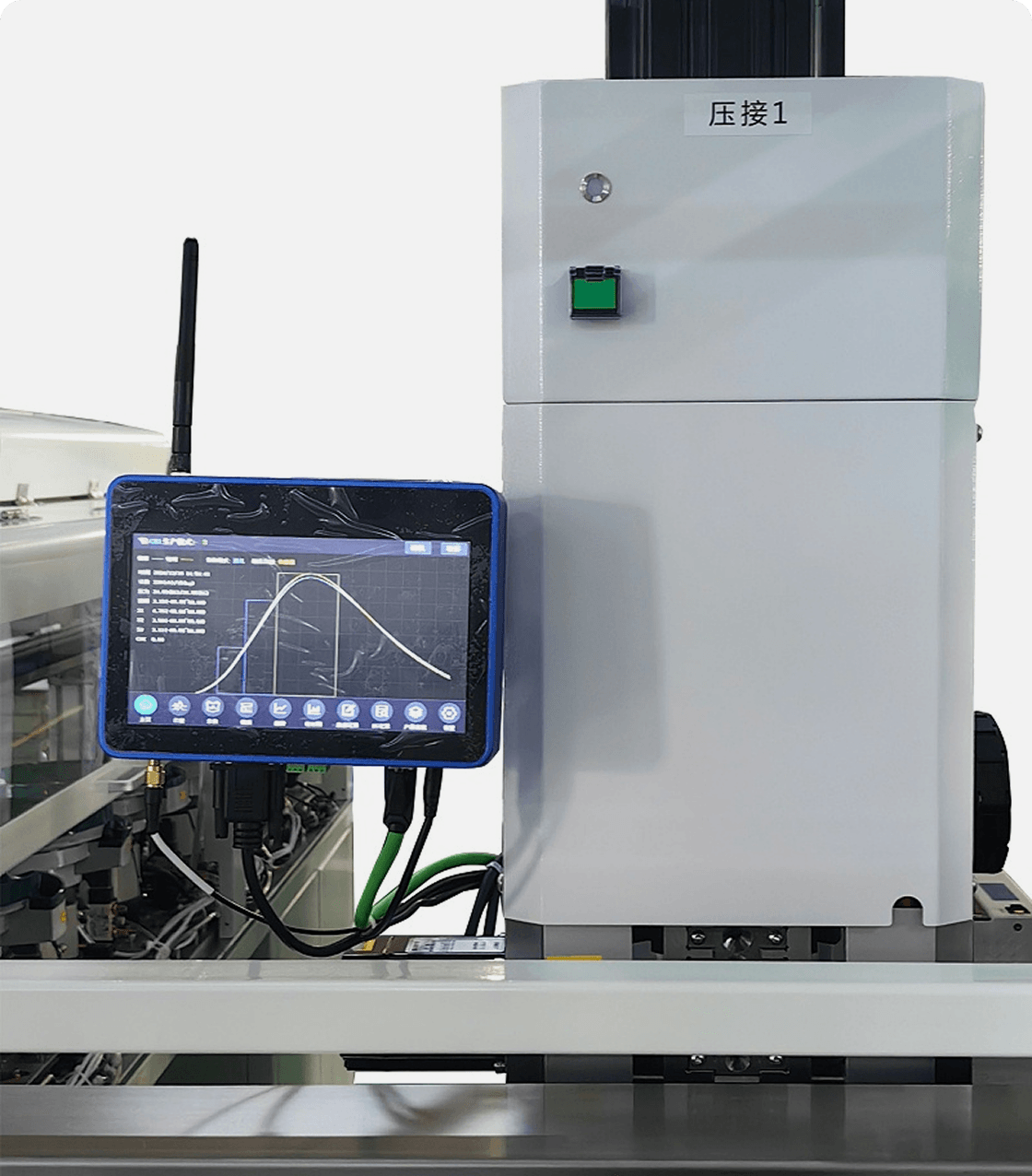

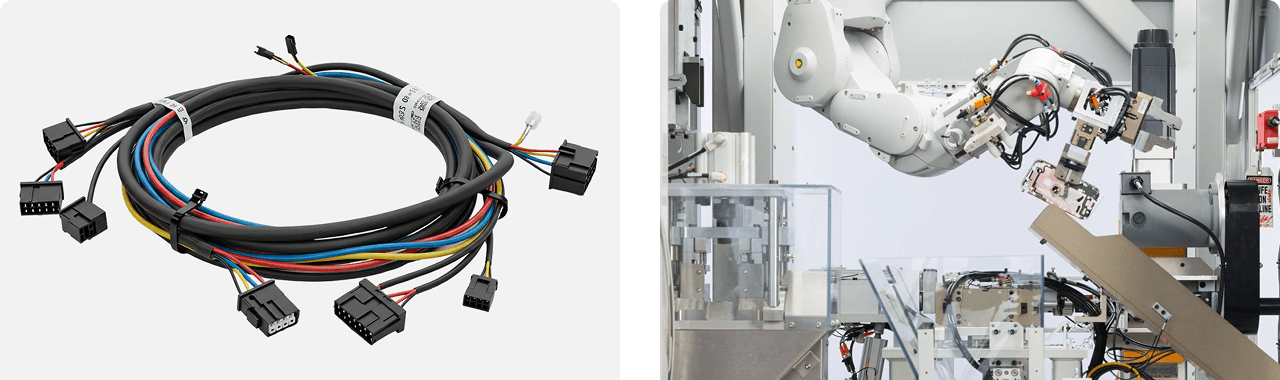

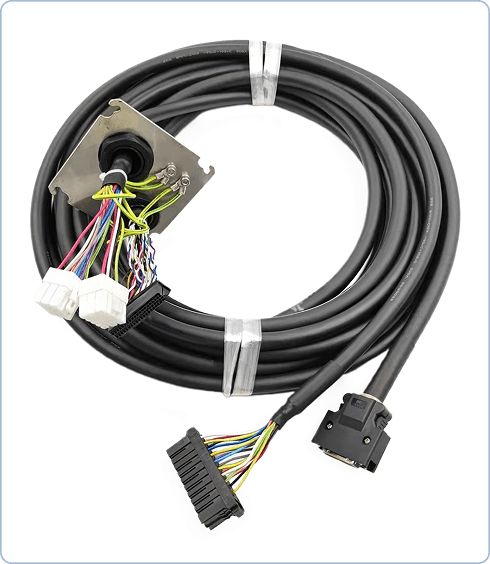

You can't have a car without an automotive wiring harness these days. A robotic cable assembly is a neat bundle of wires and cables. It makes it easier for messages and electricity to move around the car. A harness is a device that keeps cables together and saves space and mess. As a result, cars are safer and easier to build. In cars, wire harnesses lower the chance of electrical shorts and wires hanging down. Having them on hand while putting things together speeds things up. The tools here are very good at cutting, stripping, and crimping wires. Robots help people make fewer mistakes at work. We test every harness very carefully before we ship it. This makes sure that the product you get is easy to use and ready to be installed. Our process makes things better overall and cuts down on mistakes.