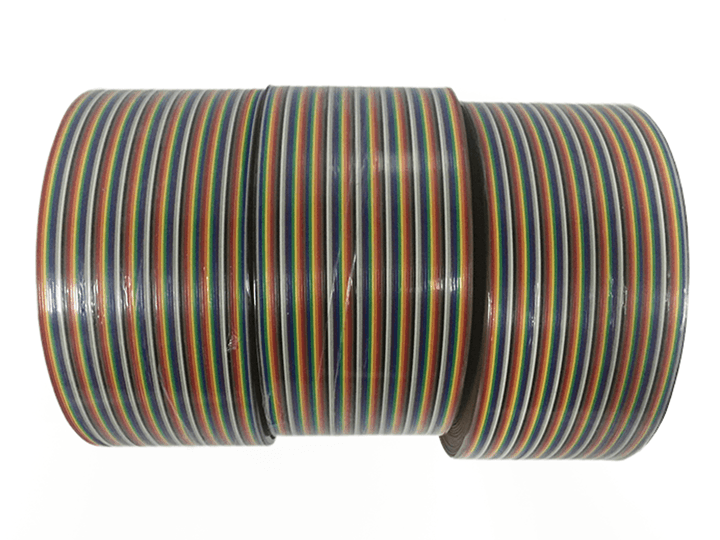

What's the Teflon flat ribbon wire

It's a teflon coated ribbon wire, high temperature coated like PTFE,FEP,PFA ETFE wires

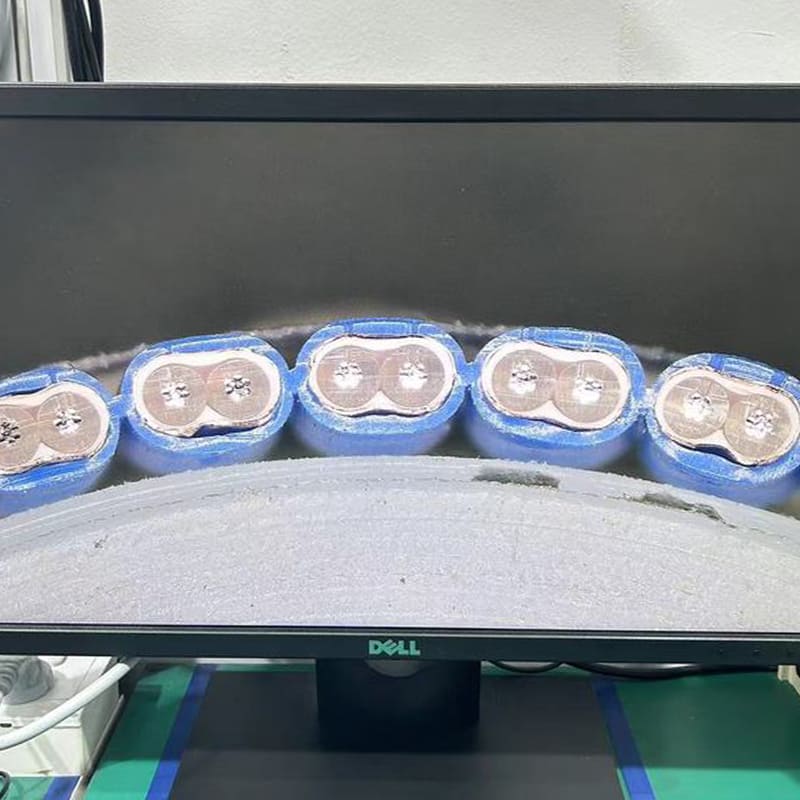

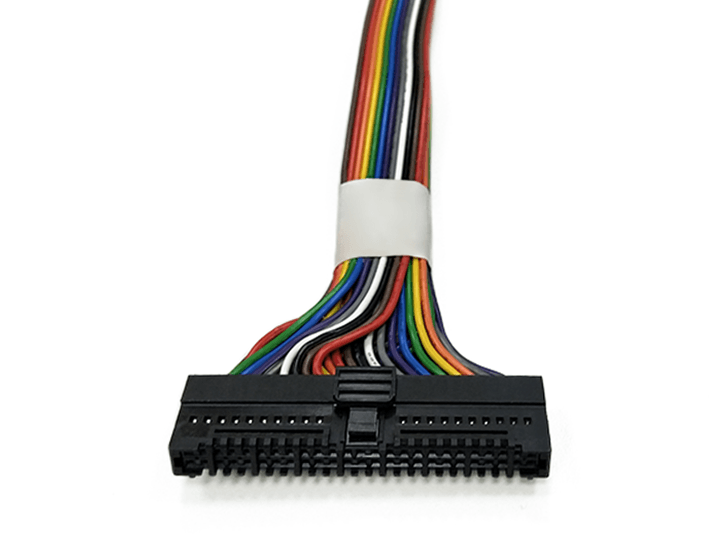

The flat, tape-like shape of Teflon flat ribbon wires hides a number of conductors. Teflon Zip Wires Terminated insulation, such as PTFE, FEP, PFA, or ETFE, surrounds each conductor. The cable is sleek and slim, so it takes up a lot less space than the round one. These teflon wire assemblies are a long-lasting way to keep high-end devices safe instead of nylon ties. Most of the time, each flat wire is soldered or connected to a connector so that it can be plugged in and used right away. People often call them PTFE wire or Teflon wire because the Teflon (PTFE) coating on the wire protects it from heat and chemicals. These ribbon cables are the best choice when accuracy and reliability are the most important things.

teflon zip wire rated temperature

PTFE and PFA can rate 250℃ FEP and ETFE can rate 200℃

Teflon Zip Wires Terminated won't break, even when it's really hot. PTFE (Teflon) or PFA insulated cables work well at temperatures up to about 200-250°C. These materials can handle even higher spikes, up to about 260°C, for short periods of time. In practice, the continuous use rating for PTFE wires is 200 °C. FEP and ETFE insulated ribbons can handle temperatures of up to 150-200°C. These grades are better than regular PVC wiring. High-temperature zip ties made of Teflon may be able to carry electricity near ovens or engines without melting. Even at these very high temperatures, the insulator and the copper core still conduct electricity. Our assemblies are unbreakable when it comes to long-term heating or quick bursts of heat because we only use materials that have been tested for these levels.