Maintenance and Troubleshooting

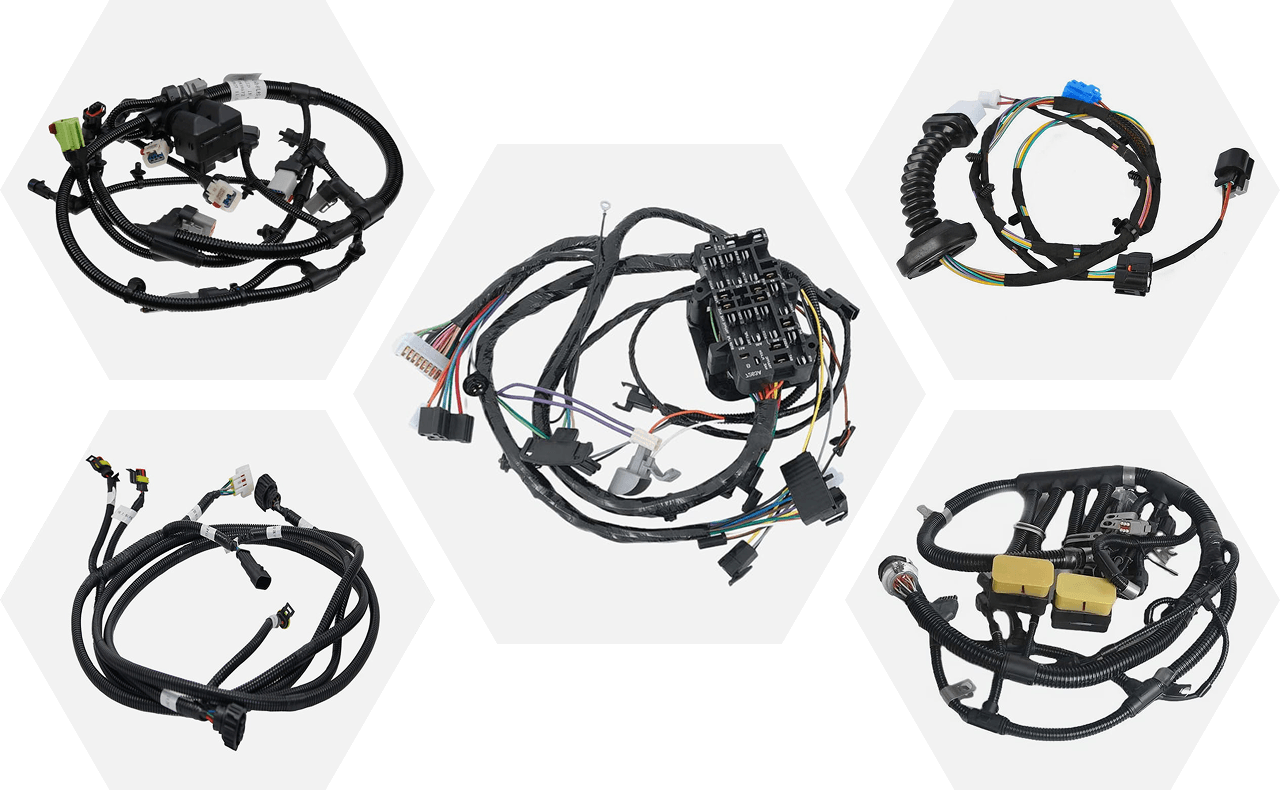

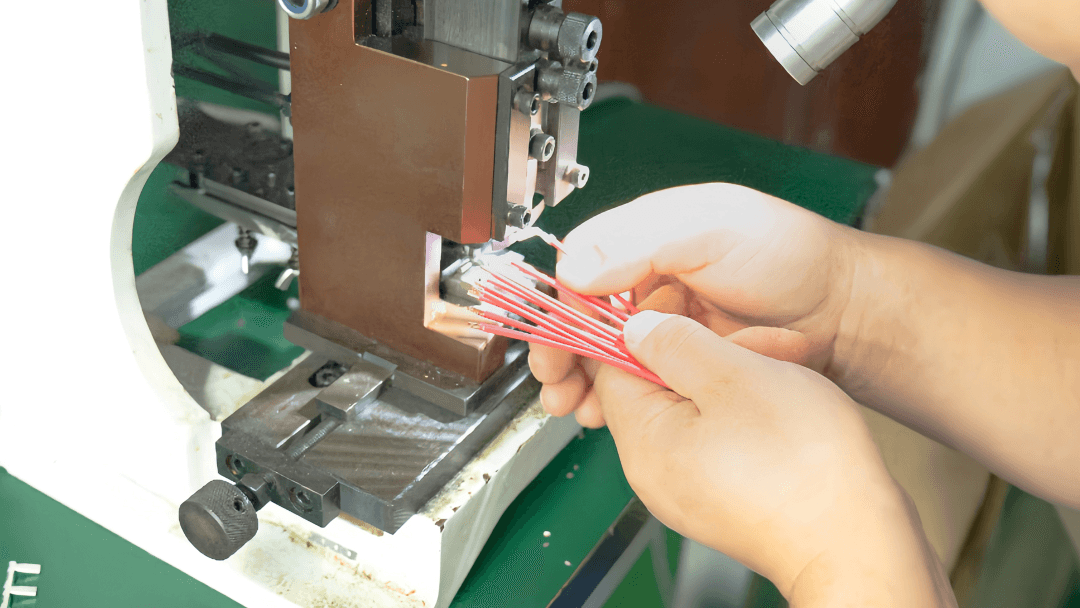

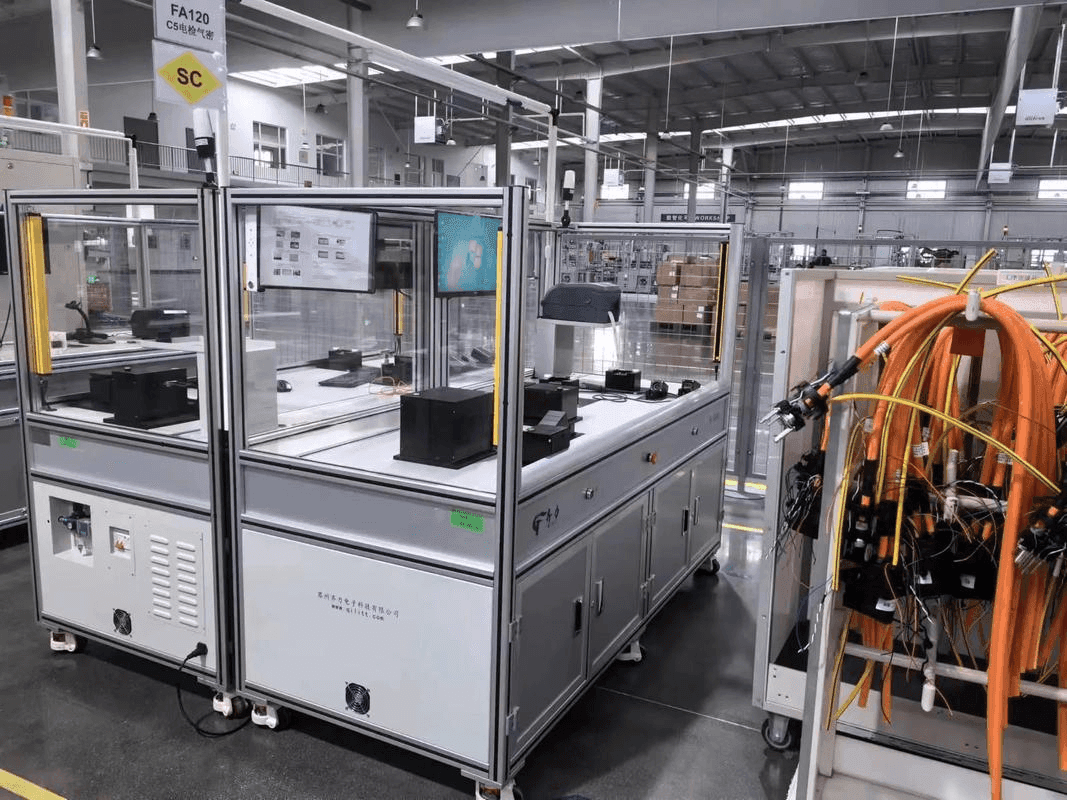

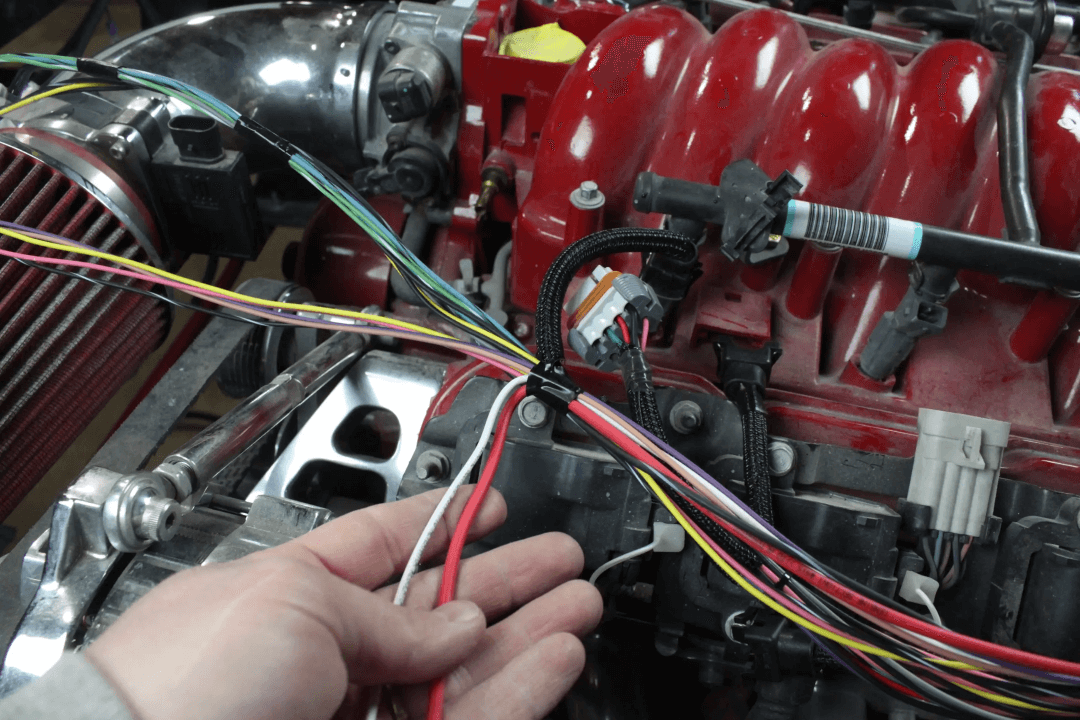

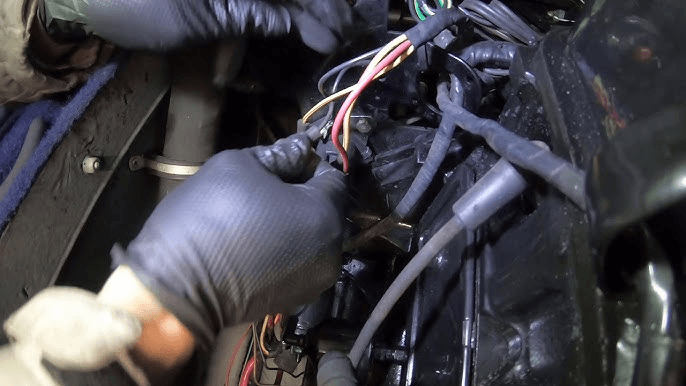

Maintaining your truck wire harness is essential for smooth and safe vehicle operation. Our truck wire harness service ensures that your wiring system stays reliable and efficient. Regular maintenance starts with inspecting all connections, terminals, and wires for wear, corrosion, or loose fittings. These simple checks can prevent small issues from becoming major problems. Cleaning contacts and applying protective sprays help extend the life of the harness, keeping electrical signals strong and consistent.

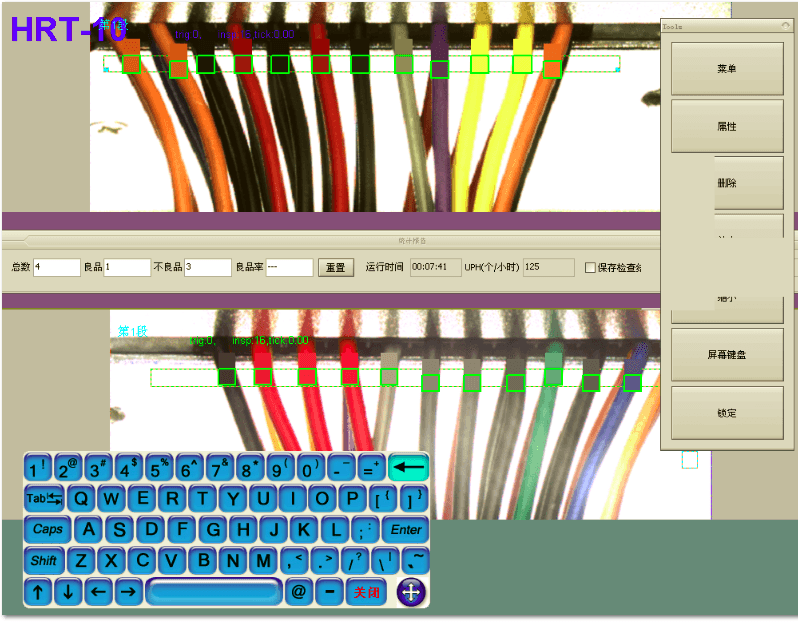

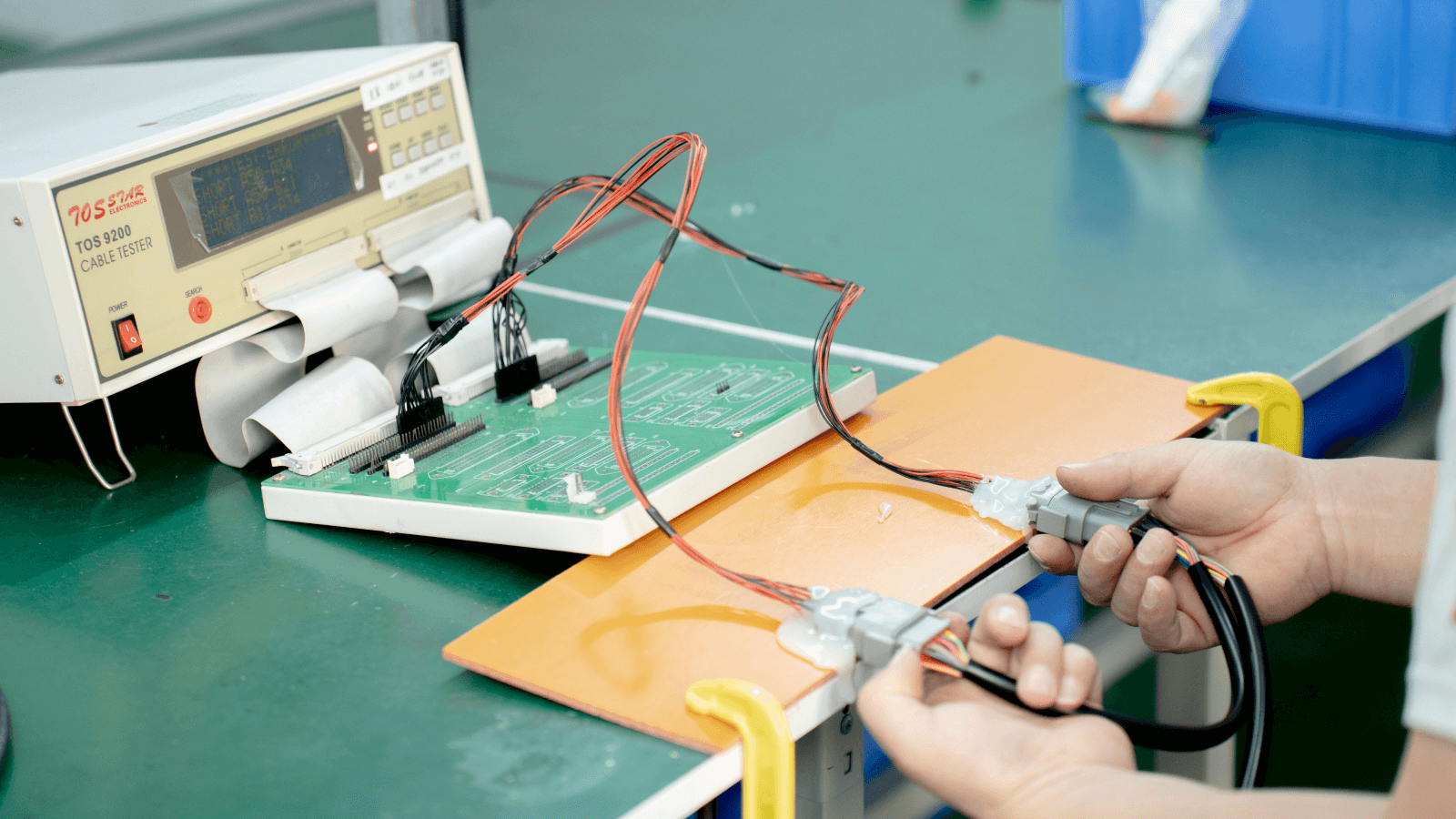

Troubleshooting is another key part of our service. If your truck experiences electrical problems, like flickering lights, malfunctioning sensors, or power loss, our experts quickly identify the source. Using specialized tools, we test each wire, connection, and fuse. This helps locate faults like broken wires, short circuits, or damaged connectors. Once found, repairs are precise, ensuring your truck returns to peak performance.

Our service also offers guidance for long-term care. We advise drivers on avoiding harsh conditions, such as extreme heat or moisture, which can damage the harness. By following these tips, you reduce the risk of electrical failures and costly repairs.