Экранированные жгуты проводов для электроники, чувствительной к электромагнитным помехам

By hdhhd shhsbbs / 2025年9月27日

For the smooth and best use of EMI-sensitive electronics use shielded custom wire harnesses. These harnesses are made to accurately fit with the electronics that are very sensitive. For the exact data transfer and high power supply use these harnesses to always have the best outcome. You can use them for various sectors. The outer shield attached with the harness keeps the harness and wire core safe and they last for many times.

Why Shielding is Key for Custom Wire Harness

Shielding is like a cover that wraps around the wires. This cover blocks outside noise and keeps the signal inside strong and clean. It ensures signals stay steady from the start of the cable to the end. Even a small bit of noise can cause errors, freezes, or shutdowns in smart devices. Because of this, индивидуальный жгут проводов assembly services often use foil, braid, or both to strengthen the protection. This lowers EMI and makes the whole system run without any trouble. Shielding also helps when wires are close together, so their signals do not mix. This is very useful when a tight space and cables are packed side by side.

Our Best Custom Wire Harness

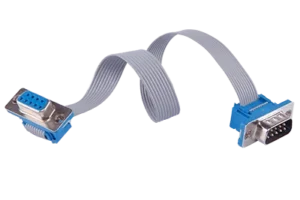

Flat Ribbon cable for Simple Layouts

A flat ribbon cable is thin, light, and very neat. It is a good choice for places where space is small and the design needs to be tidy. This type of cable keeps signals in a straight line, so they do not cross or mix with each other. That makes them safe and clear for boards, printers, and control devices. Many custom cable and wire harnesses use ribbon cables because they bend easily, lie flat, and connect without much work. They also save a lot of space and give the inside of a device a clean, simple look. They make repairs easier since following the lines and finding problems quickly is simple.

Molded SR for Strong Support

A molded strain relief (SR) gives extra strength to the weak spots of cables. Most cables tend to break near the plug ends, bending repeatedly. SR helps by adding a molded grip that holds the cable firmly and safely. It protects wires from damage even when the cable is pulled, bent, or twisted many times each day. That is why a custom wire harness with overmolding and SR is strong, flexible, and safe to use for a long time. It also makes the cable look neat and pro, which adds to trust and quality. Over time, strain relief helps cables last longer, which means fewer repairs and lower costs.

Custom OBDII Cable for Auto Use

OBDII cables connect cars to scan and test tools. They must be built with great care because they carry essential car data. A custom wire harness automotive design ensures each OBDII cable fits the right car model and works without errors. Shielding inside the cable stops data loss and keeps the readouts safe and clear. With custom wire harness length & specification, each car and tool can have the correct size, shape, and pin setup. These cables are useful for auto shops, car makers, and custom car projects. They give professional results and help with fast and safe car checks.

Custom XLR cable for Audio Gear

Audio gear always needs clear and clean sound. XLR cables are used in music studios, live shows, and significant events. A shielded custom engine wire harness or XLR cable ensures sound stays pure without hum, hiss, or buzz. Makers use strong shielding and overmolding to make these cables tough and long-lasting. They are built to handle rough use, like being stepped on, pulled hard, or wrapped quickly. A wire harness customized with the right size and shape makes sound gear work better and look pro on stage.

Prototype and Low Volume Needs

Not all projects need large builds right away. Some groups first need a индивидуальный жгут проводов prototype service to test ideas and fit. This early step helps them fix problems before bigger costs come in. Later, a custom wire harness low volume production run is excellent for smaller orders. It lowers risks, saves money, and gives strong and positive results. Small groups or start-ups can test new ideas in real devices without spending too much. This step provides fast feedback and helps build trust before moving to large runs.

Industrial Machinery Use

Large machines often work for many hours in hot, dusty, and oily places. A индивидуальный жгут проводов for industrial machinery is built with thick jackets, strong shields, and wires that can handle stress. It must fight heat, oil, and sometimes even water. Shielding is also essential here because motors and power lines make strong EMI. The shield blocks this and keeps the signals clean and safe. These harnesses are also easy to test and swap, which saves time when machines need repair. A strong design means longer machine life, fewer risks, and less downtime.

Why Choose a Custom Manufacturer

A custom wire harness manufacturer does more than just make parts. They help with design, testing, and the final build. They can turn a simple plan into a safe, working harness. They also make custom wire harness length & specification that matches what each client needs. With wire harness customized for size, shield, and shape, the result is a harness that works right and lasts long. This builds trust, saves money, and gives users a harness that works well from the first day.

Cable Options at a Glance

| Cable Type | Лучшее применение | Ключевая особенность |

| Flat Ribbon | Small and tight devices | Thin, bends well, keeps signals clear |

| Формованный SR | Daily-use gear | Strong grip, neat look, long life |

| Пользовательский OBDII | Cars and auto tools | Fit per model, shielded, safe data |

| Custom XLR | Audio & events | Clear sound, tough shield, stage use |

QL-Custom: Your Reliable Partner

For safe, strong, and pro harnesses, trust QL-Custom Technology Ltd. They make custom wire harness automotive, industrial, and audio applications with shield and overmold. They also give custom wire harness prototype service, design support, and small or large builds for any need. With complete custom wire-harness assembly services, you get design, testing, and building in one place. Visit their site to learn how they can create custom cable and wire harnesses made just for your project.

Вопросы и ответы

Can I order small amounts of harnesses?

Yes, you can order just a few harnesses if that is what you need. This is called low-volume production. You can even ask for just one piece as a prototype to test before ordering more. A custom wire-harness prototype service lets you check if the size, fit, and function are all right. This way, you save time and money. You do not need to buy many pieces before knowing if it works. Small orders also give you the chance to make changes if required. This makes the process safe and smart.

What makes a custom harness better than a standard one?

A custom harness is built for your needs. It is not the same for all. You choose the size, the shape, the length, and the parts. You can ask for jackets that resist heat, water, dust, or cold. You can add molded strain relief or overmolding to make it stronger. A custom harness fits your gear without waste or gaps. It gives more prolonged use and better results. With a wire harness customized for your device, you know it will match and perform well.

Do shielded harnesses cost more?

Yes, shielded harnesses often cost more than plain wires. But the extra cost is worth it. They block noise, protect signals, and stop errors. They last longer, which saves you from repairs. They also preserve expensive tools from damage. In the end, they save you money by avoiding downtime and failures. A shielded harness is not just a wire but a wise choice for safe and steady work.

How does overmolding help a harness?

Overmolding adds a thick cover to the weak parts of a harness, like ends and bends. This cover keeps the wires from breaking or cracking when bent. It also blocks water and dust from entering. Overmolding makes the harness stronger, cleaner, and more professional in appearance. A wire harness with overmolding will always last longer and work more safely.

Can shielded harnesses be used outdoors?

Yes, shielded harnesses can be built for outdoor use. They can have jackets that fight off the sun, rain, dirt, or heat. They can even stand against cold, salt, or harsh weather. They are used in farm tools, outdoor machines, and cars. With the right design, they last for years outdoors. They give strong, safe, and steady performance despite rough weather.

Люди также спрашивают

Are flat ribbon cables shielded?

Flat ribbon cables can be plain or shielded. The shielded ones are best when you need clean data without noise. They are slim and easy to fit in tight spots. They are common in busy systems where many signals move close together.

Why use custom OBDII cables?

Custom OBDII cables fit your car well. They plug in tight and read data safe. They are used in tests, scans, and repairs. They are strong and last longer. A custom wire harness automotive use, like OBDII, is safe and competent.

Do XLR cables need shielding?

Yes, XLR cables need shielding. This keeps sound free from hiss or hum. Shielded XLR cables give clear audio, which is why they are used in music, stage, and pro sound systems.

What is strain relief in a harness?

Strain relief is a part that holds wires tight near the ends. It stops pulls and bends from breaking them. This makes the harness strong and long-lasting. Molded strain relief is even better since it is shaped to fit the wire.

How long do shielded harnesses last?

Shielded harnesses can last many years. With strong jackets and good care, they last even longer. They handle heat, cold, and stress well. They are built for safe and long use in hard places.

Can shielded harnesses handle heat?

Yes, shielded harnesses can be made with jackets that resist high heat. They are used in hot cars, engines, and machines. They stay strong even when the heat is high. A custom engine wire harness is made for such hot areas.

What is low-volume production?

Low-volume production means making just a few harnesses. It is suitable for tests, small projects, or trials. It cuts waste and saves money. It lets you check if the harness works before making more. A wire harness low volume production is best for this.

Who makes shielded custom harnesses?

A custom wire harness manufacturer like QL-Custom Technology Ltd. makes them. They design, build, and test each harness to fit your needs. They also offer custom wire-harness assembly services for many tools and machines.

Can harnesses be made in any length?

Yes, with custom harness length & specification, you can pick the length you need. Long or short, it can be made to fit your device. It can also be shaped to fit tight or wide spaces.

Are shielded harnesses safe for medical tools?

Yes, shielded harnesses are safe for use in medical tools. They keep signals steady in scans, tests, and other devices. They protect life-saving gear from noise and errors. They are significant in health tech, where precise data is a must.

Пользовательские жгуты проводов с диаграммой