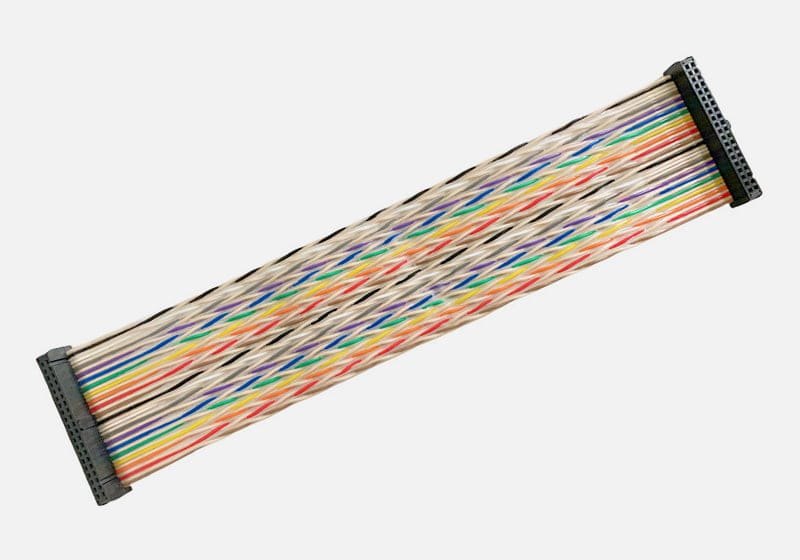

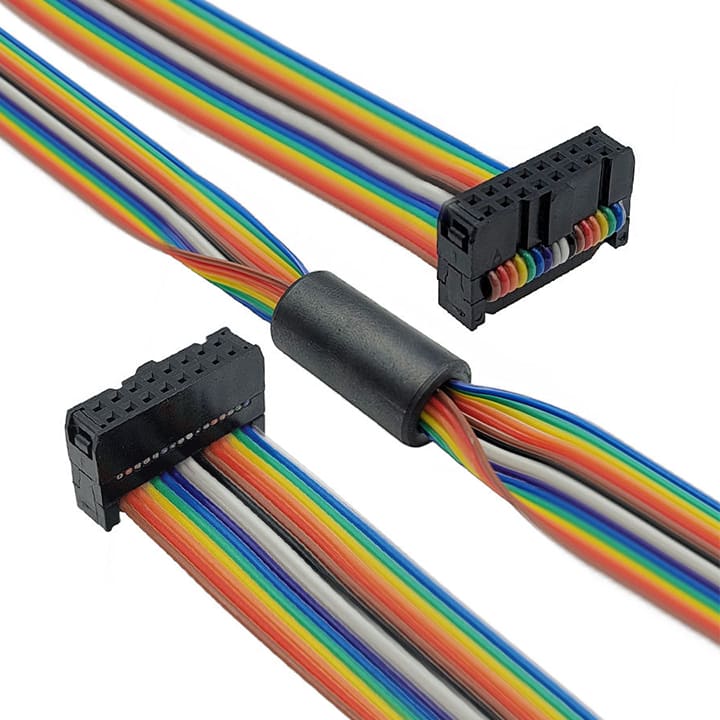

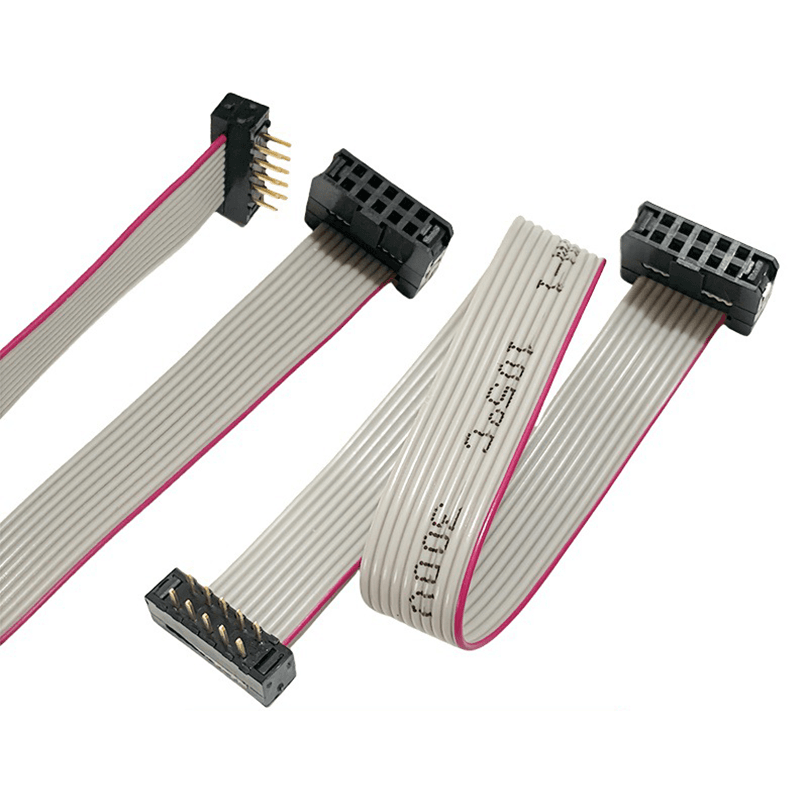

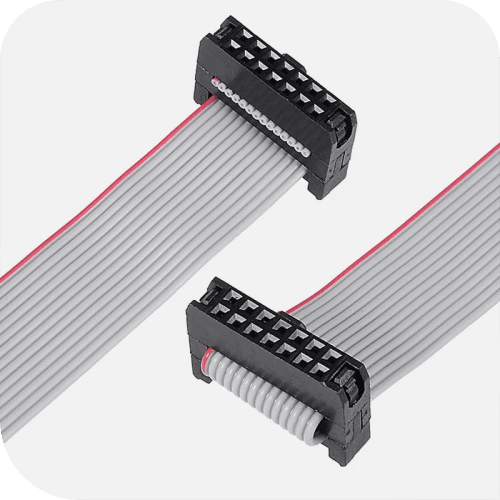

Pierce IDC connector and cable assemblies

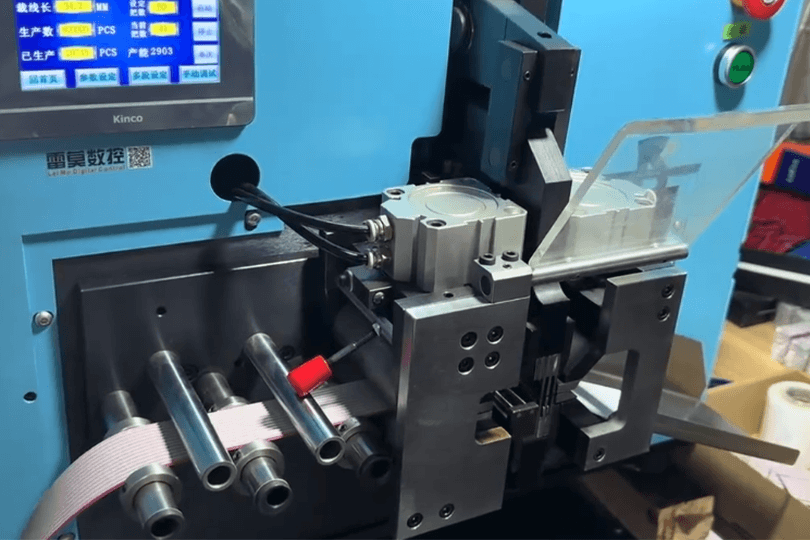

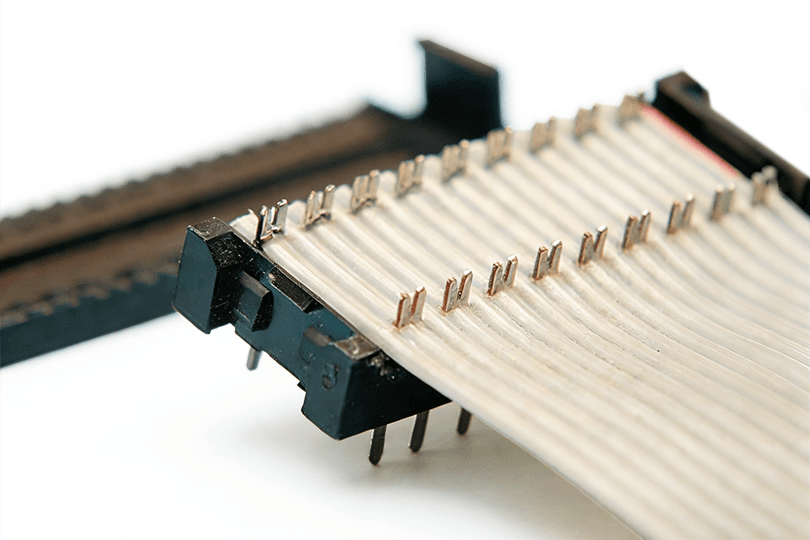

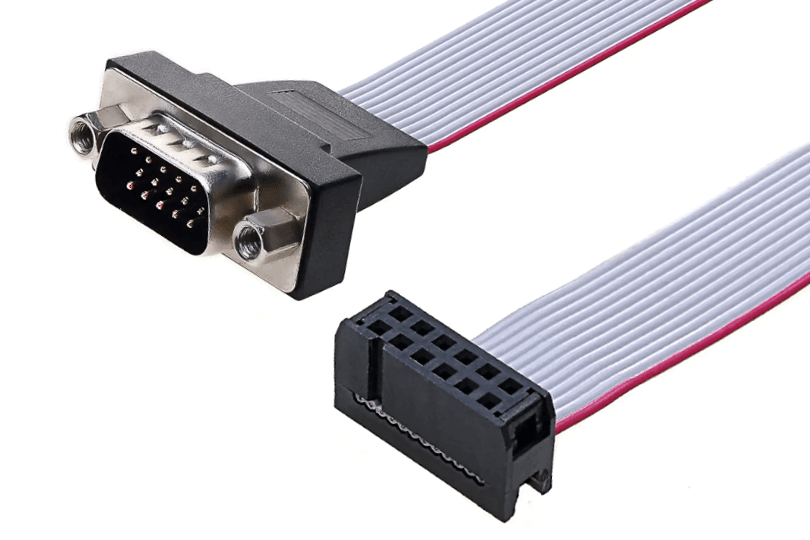

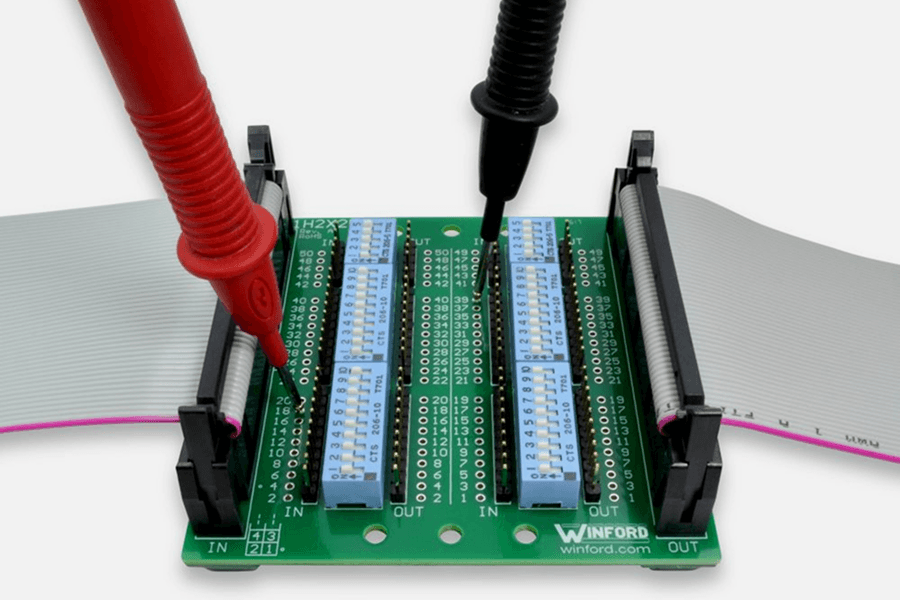

Our IDC ribbon cable assemblies use Pierce IDC connectors to connect wires quickly. These connectors cut into the wire insulation and make contact in one press. This method is called insulation displacement. One connector can connect many cables simultaneously. Inside the connector are fork-shaped metal contacts. They slice through the plastic coating and grip the copper wire tightly. This creates a strong connection with low power loss. The process can be done by machine or with simple tools, so it is faster than soldering by hand. We can build custom ribbon cable assemblies to match your design. This includes special lengths, wire layouts, or connector types. These cables are used in computers, home electronics, and industrial machines. At QL-Custom, every IDC ribbon cable assembly is carefully made and tested to ensure good quality and long life.