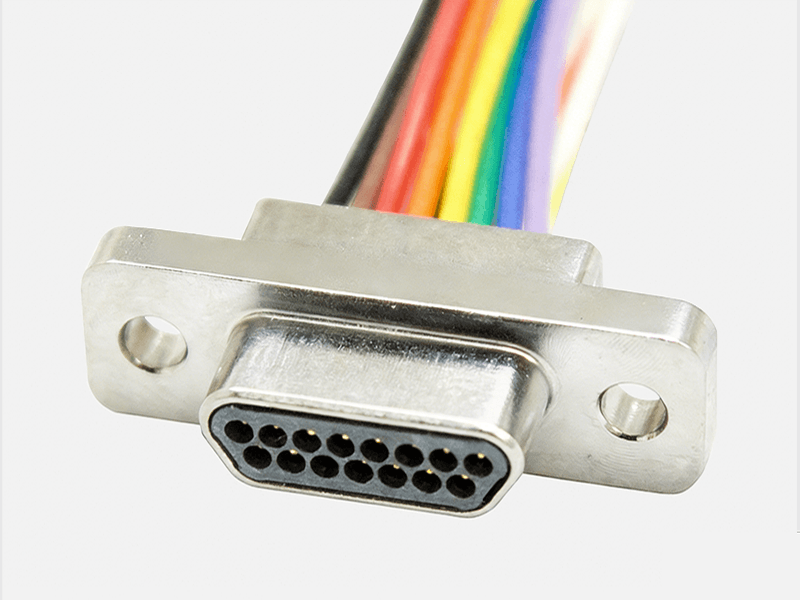

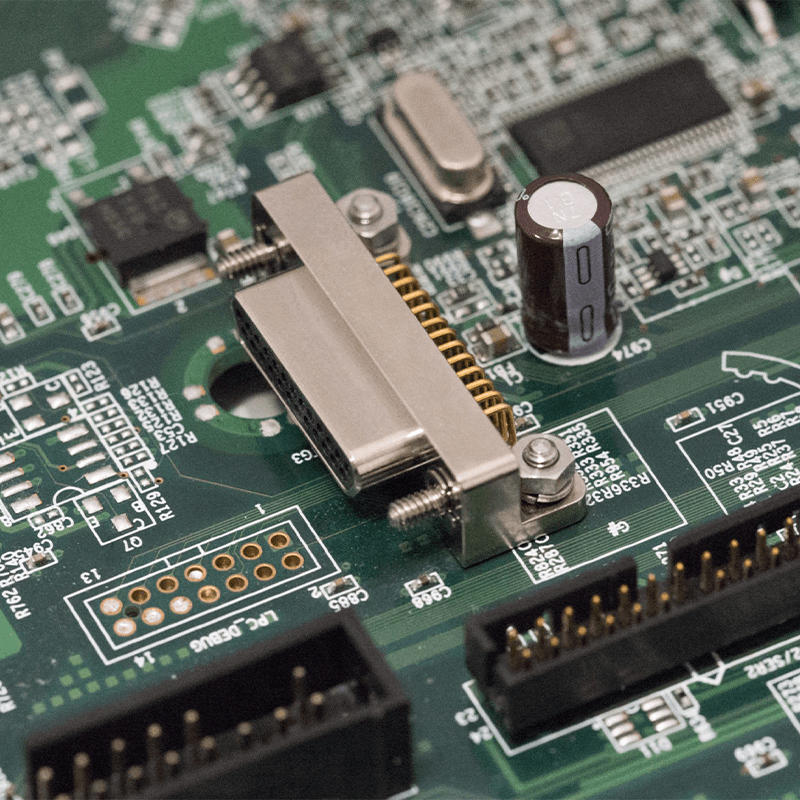

Overmolded Cable Assemblies

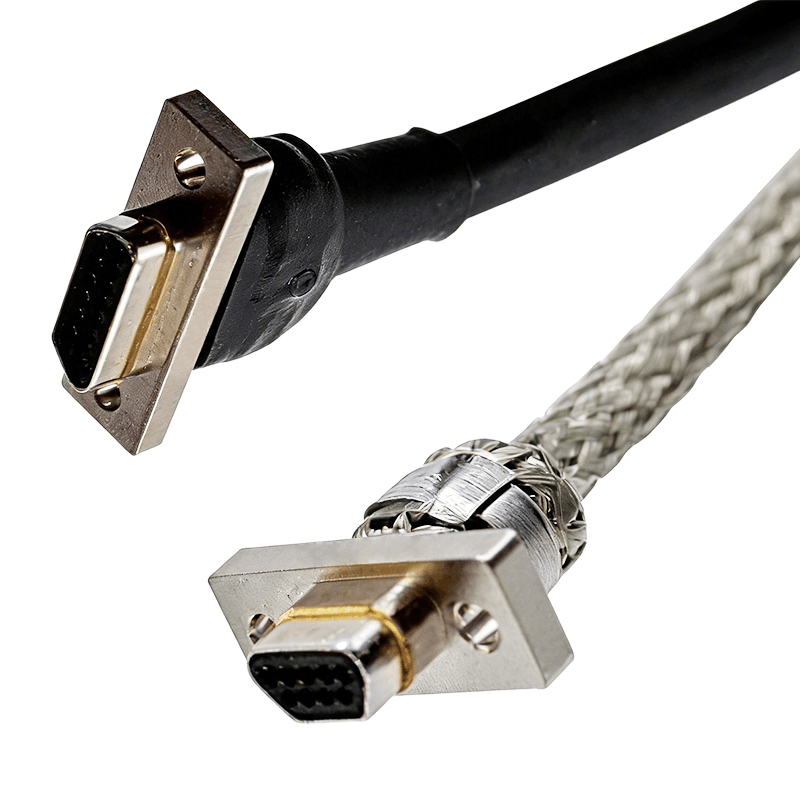

Overmolding is a common part of the connector interfaces on our Micro D cables. Overmolding the connection and cable into one part makes them stronger. This built-in housing keeps moisture out and absorbs shocks. Overmolded assemblies are better able to handle tough situations because they provide full strain relief at the cable exit.

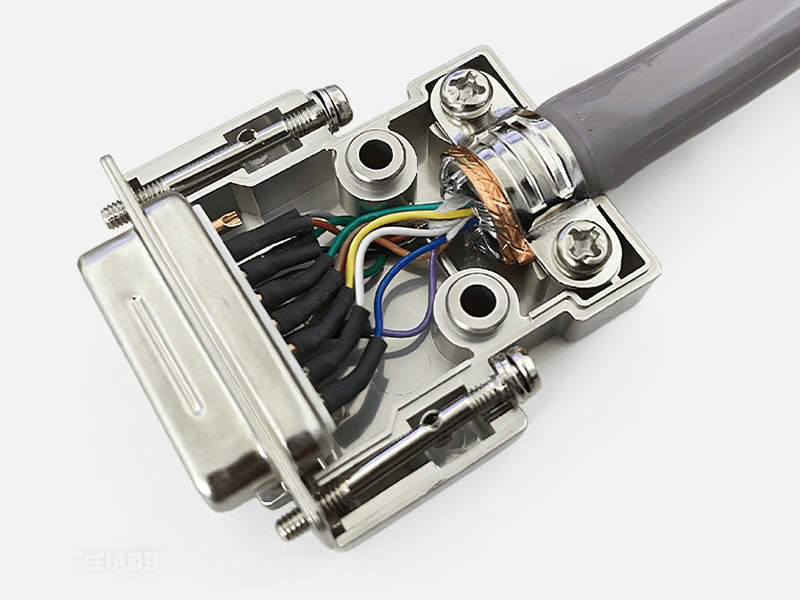

Strain Relief Boots

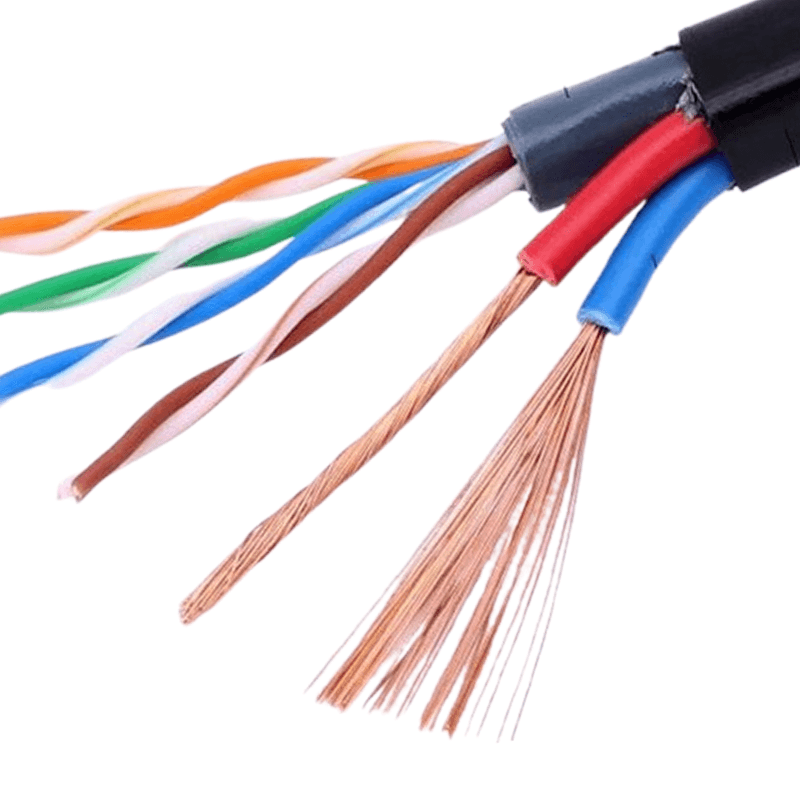

We also offer strain relief boots and backshell clamps to hold the cable jacket in place, in addition to overmolds. The entrance point is a common weak spot, but these fasteners stop it from bending. They lower the tension, which stops vibration from damaging the internal wires and crimp joints.

Vibration Rated

Our assemblies are designed to work even when conditions change. We use glue around pins as an optional part and mil-spec bushings to stop vibration. Because of this, the micro D cable assembly stays firmly connected even when it is shaken and stressed a lot.

Shield Bonding

The strain relief also holds the shell in place with the cable shield braid. Connector shells that are properly bonded can act as Faraday cages, protecting communications from electromagnetic interference (EMI) even in very loud places.

Every step follows ISO rules to make sure each harness is safe and the same.