Since 2013, QL-Custom has been delivering advanced hot runner systems tailored for high-value plastic applications. Designed to reduce material waste and optimize production efficiency, our systems help customers significantly lower material costs.

With over 4 years of specialized experience in hot runner system design, we offer flexible solutions to meet diverse flow channel requirements. Our team includes highly skilled mould designers and experienced mould masters, ensuring precision, reliability, and on-time delivery for every mould set.

In addition to mould manufacturing, QL-Custom provides complete end-product production, supported by our efficient injection moulding lines. This full-service capability ensures quality control from design to delivery.

>> What is Hot Runner System Mold

The Hot Runner System is a system for molding which saving the materials usage, the materials runner extensive a longer way getting closer to the mold cavity. Hot Runner System working without wasting plastic. It saved a lot especially for some expensive materials. It is popular although the cost is higher than current mold design during large q’ty production.

The hot runner system is divided into a fully hot runner and a semi hot runner. Fully runner design is complex, but the effect is good and maintenance costs are very low. Semi-hot runner structure is simple, stable and easy to use, low failure rate, because the structure is simple ,therefore low maintenance costs, the stability of the production have a greater guarantee. Hot Runner System classification: open (for semi-hot runner), needle valve type (for fully runner).

>> Hot Runner System assembling case study

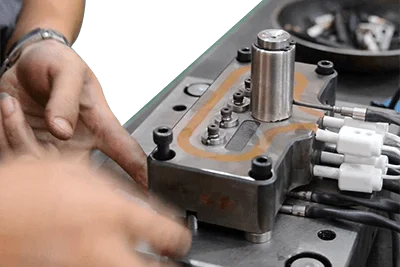

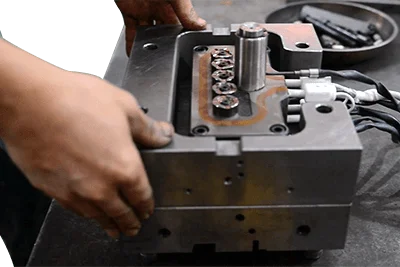

- Set up the mold, flat on the mold, with the wind to clean all the holes and templates.

- Check the size of each hole, focusing on the depth of inspection. Clear the burrs on the template. Also check the screw hole of the lock manifold and whether the center nail and the anti-pin hole are finished. This place for the first time to do the hot runner mold master often missed.

- The hot mouth seal bit and the stage of the two parts with the mold with the red red.

- The hot Tsui test equipment, and then remove the check seal bit

(1) whether to rub red red, stairs bit

(2) No touch the mold. If not, stop the installation, check the cause of the error to adjust. To ensure that with the tight without leakage material. This process should be careful not to touch the tip of the tip. - Will be installed all the hot Tsui, while the installation of the center pad, the center pin, anti-dump sales. And in its plane sweep red.

- Check the Tsui plane and center pad height, the error control within 0.05mm.