Get Accurate Production: Custom Wire Harness Manufacturers

By hdhhd shhsbbs / 2025年8月12日

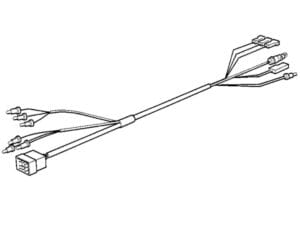

Almost every electric machine needs a wire harness for power and signal supply. Best and the leading custom wire harness manufacturers always use top quality wire harness design and materials for making the harness. They make sure everything is working exactly before delivering it to you by checking the harness. And they always follow the safety rules when building the harness to ensure it will not harm the system. A fine quality harness always makes differences when working on a project.

Custom Wire Harness Manufacturers for Top Results

Choosing the right شركات تصنيع أحزمة الأسلاك المخصصة is a big step when you want safe, strong, and dependable parts. These harnesses affect the safety, strength, and life of your products. Skilled شركات تصنيع أحزمة الأسلاك المخصصة take time to plan each step. They pick the best materials, cut wires correctly, and carefully fit each part. They test every wire and cable to ensure it works well before sending it to you. This careful work means your products will last longer, work better, and save you time, stress, and money.

Why Skilled Wire Harness Assembly Company Matters

A trusted wire harness company uses trained workers, modern tools, and a clear plan to build harnesses correctly. Custom wire harness manufacturers follow safe steps and check quality at every stage. Every task is done with care, from measuring and cutting to adding connectors and final testing. When you get your harness, it will be ready to use, fit well, and work immediately.

Benefits of a Skilled Wire Harness Assembly Company:

1- High-quality parts you can count on

2- Fast delivery without late orders

3- Lower risk of product failure

4- Same good quality every time

5- A team that listens to your needs

6- Can make small or big orders

| الميزة | المزايا |

| Quality parts | Long life and safe use |

| Fast delivery | No production delays |

| Low failure rate | Less repair costs |

| Consistent quality | Same standard each time |

| Custom support | Meets your exact needs |

| Flexible orders | Small or big runs possible |

Custom OBDII cables: for Fast and Accurate Car Data

Custom OBDII cables help car repair shops, garages, and auto custom wire harness manufacturers. They plug into the car’s computer to read data. This helps find problems faster, plan repairs, and check work after fixing. These cables are strong and made for daily use in busy places.

Why Selecting Custom OBDII Cables:

Strong for daily work

Reads car data with high accuracy

Works with many car brands

Easy to use for all skill levels

Saves time in testing

| الميزة | المزايا |

| Strong build | Handles daily shop use |

| Accurate reading | Clear and correct data |

| Wide compatibility | Fits many car models |

| Easy to use | Saves training time |

| Time-saving | Faster checks and fixes |

Molded SR(Omron Switch Cable Relief): for Safer Cables

Molded SR protects cables from bending damage. Without it, cables can wear out or break fast. The cable stays strong and safe with molded SR for a long time. It also makes cables look neat and keeps them in shape.

Benefits of Molded SR:

Stops cable bending and breaking

Keeps cable shape for more prolonged use

Safer for daily handling

Makes wiring neat and tidy

Better look and reliability

| الميزة | المزايا |

| Bend protection | Longer cable life |

| Shape retention | Neat and tidy layout |

| Safety | Safer use in work areas |

| Appearance | Clean and pro look |

| Reliability | Consistent performance |

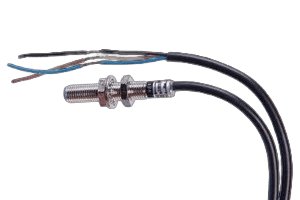

Automated sensor plug cable: for Quick and Easy Use

أن automated sensor plug cable saves time in busy work areas like production lines. It connects and disconnects quickly without losing quality. It is perfect for fast work and accurate results.

Why Choose Automated Sensor Plug Cables:

Saves work time

Handles heavy daily use

Fits many sensor types

Simple to connect and remove

No delays in production

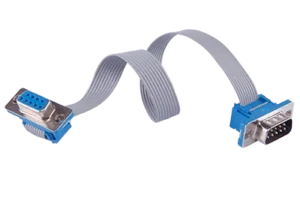

Flat Ribbon Cables: for Tight Spaces

كابلات شريطية مسطحة are thin, light, and easy to bend. They fit wAutomotive Wire Harnesse sell in small spaces where round cables can’t go. They help keep devices neat and are used in computers, printers, and control panels.

Advantages of Flat Ribbon Cables:

Flexible and light to handle

Fits in tight and narrow spaces

Keeps wiring neat inside devices

Works with many kinds of equipment

Easy to install

Role of Harness Supplier in Modern Manufacturing

Good شركات تصنيع أحزمة الأسلاك المخصصة do more than just make parts. They understand your needs, help improve designs, and choose the best materials. They can handle small runs or large orders and keep quality the same.

Services from a Good Supplier:

Help with design plans

Sample tests before big orders

Get the best materials

Flexible order sizes

Quality checks at every step

Custom Harness Solutions for Many Industries

Custom wiring harnesses are used in many fields. Cars, planes, boats, medical tools, and machines all need them. Each use has its own needs, and a good maker can meet them all.

Industry Uses:

السيارات: For safety systems, lights, sensors

Aerospace: Light harnesses for planes

Marine: Water-safe harnesses for boats

طبيًا: Safe harnesses for hospital tools

صناعي: Strong harnesses for big machines

QL-Custom: Your Partner for Quality Harnesses

QL-Custom Technology Ltd. is a trusted name for custom harness work. They make harnesses for cars, machines, and electronics. Each one is made with the best materials and undergoes strict checks.

Why Choose QL-Custom Technology Ltd.:

Many years of work experience

Many products for many fields

Friendly customer help

High-standard harness making

Visit QL-Custom Technology Ltd. to get safe, strong, and reliable harnesses made for your needs. When you choose skilled custom wire harness manufacturers, you get high quality, a perfect fit, and safe results you can trust.

الأسئلة الشائعة

What is a custom wire harness?

A custom wire harness is a set of wires arranged neatly and safely to carry power or signals. Each wire is tied, covered, and secured to stay in place, even during use. It helps machines run well, prevents damage, and makes them last longer.

Why choose custom wire harnesses?

They are made to fit your job, so every wire is in the right spot. This makes work faster, safer, and more reliable. A perfect fit means fewer mistakes and less time fixing problems.

How do custom harnesses help in production?

They save time, lower errors, and keep work flowing without sudden stops. Workers can focus on the job instead of dealing with wiring issues.

Can I get a harness in any size?

Yes. They can be made short, long, small, or large, and shaped to fit your space without waste.

What materials are used?

They are built with strong wires, tough covers, and durable connectors. These parts help the harness work well for years.

يسأل الناس أيضًا

What is a custom wire harness for machines and tools?

A custom wire harness is a carefully arranged group of wires tied, wrapped, and set into a fixed and neat shape. It is made to fit perfectly into a specific machine or tool so that every wire stays in place, remains organized, and is protected from damage during use.

Why should I use a custom wire harness for my work?

Using a custom wire harness keeps all the wires neat, safe, and easy to identify. It reduces mess, prevents tangling, and ensures that every wire fits exactly where it should, making setup and maintenance easier.

Who makes these special custom wire harnesses for you?

Skilled technicians in specialized factories create them by hand or machine. They follow your size, length, color, and shape instructions so the harness matches your project perfectly.

How do they make them right and accurate every time?

The custom wire harness manufacturers measure each wire carefully, cut it with precise tools, wrap and secure it properly, and check each step before thoroughly testing the harness to ensure it meets the required standards.

Can I get only one wire harness for my small job?

You can order just one harness for a small task or request many for a bigger project. Custom wire harness manufacturers can produce in both small and large quantities.

Do they check each harness before they send it to me?

Yes, each harness is inspected and tested for safety, correct length, perfect fit, and secure connections before shipping.

Is a custom wire harness very costly for small orders?

The price depends on the wire’s type, length, size, the number ordered, and how complex the design is.

What tools do they use to make each custom harness?

They use wire cutters, stripping tools, crimping tools, heat shrink machines, testers, measuring devices, and strong binding materials to ensure durability.

وصلة أسلاك مخصصة مع مخطط تخطيطي