Thermal Management Automotive Wire Harneses for Industry 4.0

By hdhhd shhsbbs / 2025年6月24日

Thermal Management Automotive Wire Harnesses Electric cars, smart trucks, and machines get hot when they run. Wires inside them also get hot. That’s why thermal Automotive Wire Harneses are so helpful. They stop heat and keep the system safe. These bright and strong wires help your machines work better without any danger from heat. They are suitable for sensors, engines, and more. QL-Custom Technology Ltd. has strong ones like ignition pigtails, sensor pigtails, and ISO wire harnesses. You can use them to make your system work better and last longer.

Thermal Management in Car Wires

Modern cars use a lot of wires to help all their parts work the right way. These wires carry power and signals to the engine, lights, air conditioning, and sensors. But when these wires carry a lot of power or sit too close to parts of the car that get very hot—like the engine or exhaust—they can get too hot themselves. If the wires get too hot, the outer cover can melt, and the wires inside can break or stop working. In some bad cases, this can cause the car to stop running or even catch fire.

Thermal management is a way to stop car wires from getting too hot. This helps the wires stay safe, last longer, and do their jobs properly. A car with good thermal management in its wires will work better and have fewer problems.

At QL-Custom Technology Ltd., we make special أسلاك أسلاك السيارات built to handle high heat. We use strong and trusted materials. We also test every wire to make sure it will not overheat. We design wire harnesses for all types of cars and trucks, and every automotive wire harneses is made with great care so your vehicle stays safe, even in harsh conditions.

Hot Wires Are a Big Problem

Car fires are essential because they help many parts of the car work by sending power or signals. But when these wires are placed near hot spots like the engine or exhaust pipe, they can become damaged by heat. If a wire cover melts, the cables inside may touch each other, which can cause short circuits, sparks, or even fires.

Even a slight increase in heat can be a big problem. For example, if a wire gets just 5°C hotter than it should, it may wear out 30% faster. This means the wire will stop working sooner and may need to be replaced earlier than expected.

When we use good thermal care, wires stay cooler and last much longer. This is not just about safety—it also saves money. You don’t need to fix or replace wires as often. QL-Custom Technology Ltd. always focuses on strong heat protection when building every automotive wire harneses.

Things that Makes Wires Get Hot

There are several reasons why wires in cars can get too hot:

- Wires that carry a lot of power can heat up.

- Wires placed near engines or exhaust systems absorb heat from those parts.

- Wires that are packed too close together can trap heat.

- Wires made from cheap or weak materials may not handle heat well.

At QL-Custom Technology Ltd., we solve these problems by designing each custom automotive wiring harness smartly. We use the best materials and make layouts that help wires stay calmer and safer.

Parts That Help Keep Wires Cool

We use strong parts and innovative designs to ensure wires do not overheat. These are some of the things we use to keep heat away from wires:

- Pure Copper Wires: These carry power better and stay cooler than others.

- Heat-Resistant Covers: Covers made from PTFE, XLPE, and silicone are excellent at handling high heat.

- Heat Sleeves: These are special wraps that go around wires to block outside heat.

- Better Layouts: We ensure wires are spaced apart so air can flow between them.

- Shiny Tape: This tape reflects heat away from wires, keeping them cooler.

Heat Ratings of Wire Materials

Material | Heat Limit (°C) | أفضل استخدام |

| بولي كلوريد الفينيل | 70°C | Inside the car in cool places |

| XLPE | 125°C | Under the hood near the engine |

| سيليكون | 200°C | Very hot areas following engine parts |

| PTFE (Teflon) | 250°C+ | Super hot zones like near the exhaust |

When we use the right materials in the right places, we can build the best wiring harness for car engine or even heavy trucks that face very hot conditions.

Smart Testing and Design

Before we send out any automotive wire harneses, we test it very carefully. We heat the wires, bend them, and shake them to see how they act under pressure. Our machines check for weak points. If we find anything wrong, we fix it right away.

We also use special computer programs to plan out the best layout for the wires. This helps us place the cables in spots where they will stay cool. We add extra wraps or sleeves in areas that will get hotter. Our main goal is to make sure every custom wiring harness for cars is safe, strong, and built to last.

How We Use Industry 4.0

Industry 4.0 means using innovative tools and machines to build better products. At QL-Custom Technology Ltd., we use these new tools in our factory to build better أسلاك أسلاك السيارات:

- Sensors watch the wires as we build them to check for problems.

- Robots cut and connect wires with great speed and accuracy.

- Digital Records keep track of how each harness was made.

- Auto Scanners quickly find issues, so we can fix them fast.

These innovative tools help us make better, safer, and faster custom car wiring harness products with minimal waste.

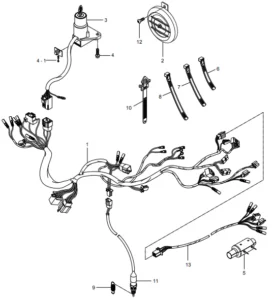

Kinds of Wire Sets Available

We build many kinds of automotive wire harneses, and all of them are made to handle heat safely:

- Automotive sensor harness: These go near hot parts of the engine and use strong covers. These connect to sensors near fuel, oil, or heat sources.

- Ignition pigtails: These carry sparks to start the engine and must be heat-safe. These are vital parts for the wire system.

- Sensor pigtails: These are simple, plug-and-play sets for easy radio use. These are mainly used for controlling the sensors.

- ISO wire harness: These are bigger, stronger, and made for tough jobs. These harnesses can easily handle heat.

We also create custom made wiring harness kits. We will build it for you if you tell us what you need.

Reasonable Points to Pick QL-Custom

- Enough years of experience in making automotive wire harneses.

- Fast replies and deliver products quickly.

- Our factory is certified for high safety and top quality.

- We use intelligent machines and skilled workers.

- We ship our products to customers all around the world.

We help big car companies, repair shops, and custom car builders. No job is too small or too big. Every automotive wire harneses we make is strong, safe, and thoroughly tested. Your safety is our top goal. That’s why every custom wiring harness for trucks or cars is made with extra care and innovative design.

Thermal Management Automotive Wire Harneses To keep your machines safe, your wires must stay cool. These thermal harnesses stop heat and keep wires safe. They are smart and made for today’s cars and trucks. You can trust QL-Custom Technology Ltd. to give you the correct cables. Try sensor pigtails, ISO harnesses, and more for better and safer work.

Thermal Management in Automotive Wiring Harnesses for Industry 4.0

Do you want wires that are safe and made to last?

Do you need an automotive wire harneses that fits your car or truck perfectly?

Then let QL-Custom Technology Ltd. help you. You can order your own car wire kit or harness wiring kit today. Our team is here to help you pick the best option. With our help, your car or truck will run better, last longer, and stay safer. Contact QL-Custom Technology Ltd. today or ask us for a free custom quote. Let us work with you to build a safer and better future for your vehicles!

الأسئلة الشائعة

What is thermal management?

Thermal management means keeping things cool. It helps wires and machines stay at the right temperature while they work. This stops them from getting too hot and breaking.

Why does heat matter?

Too much heat can hurt wires, damage machines, and sometimes even start fires. That’s why it’s so important to control heat, especially in machines that work all the time.

How do these harnesses help?

These special Automotive Wire Harneses are made to take heat away from the wires. Some have fans or sensors to help cool things down. They keep the wires and the machine working well.

Where are they used?

They are used in smart cars, robots, and high-tech factories. These places need machines that work hard and fast without getting too hot. The harnesses help them do that.

Are they part of intelligent systems?

Yes, automotive wire harneses work with other smart parts in the machine. Together, they help the whole system work better and stay safe. This is important for modern factories and new electric cars.

يسأل الناس أيضًا

What is a thermal wire harness?

It is a group of wires that helps keep things cool. It stops the wires from getting too hot. This keeps parts safe. It helps prevent things from breaking. It is used in machines and cars.

Why is heat control key in cars?

Too much heat is bad for cars. It can break wires and parts. A thermal wire helps stop that. It keeps the vehicle safe. It keeps the cables cool and working.

What is Industry 4.0?

It means using innovative tools and machines. These machines can work with each other. They help you work faster and better. They use tech to do smart jobs.

How do these wires help smart cars?

These wires stop too much heat. They also move data fast. This helps smart cars work better. It helps them stay calm and safe, too.

Can it work in fast cars?

Yes. These wires are made for speed. They can handle fast cars. They are strong and do not break. They keep working even in hot places.

Is the wire strong for prolonged use?

Yes. It is made for long work. It does not wear out fast. It stays strong for many years. It helps your tools last longer.

Does QL-Custom make these wires?

Yes. They are experts. They make wires that are strong and safe. They help you get what you need.

Can I ask for a custom heat wire?

Yes. You can tell them what you need. They will make the correct wire for your job. You can choose the size and shape.

Does it help with car safety?

Yes. It keeps wires from getting too hot. This helps stop fires. It keeps your car safe to use.

Where do we use it most?

It is used in cars, in big machines, and in factories. It is suitable for tools that get hot. It is made for challenging jobs.

Automotive Wire Harneses & Diagram