Sichere Autoverkabelung mit starken Kabelbäumen für Autos

Cars need wiring that can handle rough driving without putting safety at risk. The car's wiring is like a network of veins that moves electricity and data around the car. Durable automotive wire harnesses help all the parts of your car work together in perfect harmony. Each wire is protected by a strong harness, and the GPS, sensors, and computer systems are safe from short circuits. Harnesses protect people from dirt, the weather, and physical harm. It keeps your car stable and strong every day. No matter how many miles you put on it, every vehicle, from small cars to big trucks, needs secure wiring to keep running well. Strong Automotive Wire Harnesses Heat, vibration, wetness, dust, and time are all hard on cars. A melted or broken wire could cause problems or make the system not work right. Companies that make custom automotive wire harnesses make sure their products can handle these kinds of loads. They use materials that last a long time and can handle heat, humidity, and pressure. Sturdy wire harness connectors make sure that every part fits snugly in cars. The car wire harness cover, on the other hand, protects it from dust and damage. Each bundle of wires is carefully wrapped and checked twice to make sure that power and data can flow smoothly. A high-quality harness will keep your car safe and working well for many years. It does more than just connect. Safe Wiring for GPS and OBD Systems Your car's GPS and OBD systems require clean signals and stable power to function correctly. Even a small cut in the wire can cause data to fail or result in errors. This is why careful automotive wire harness assembly is so important. Layers of automotive wire harness cloth tape and automotive wire harness...

Mehr lesen "High Temperature Automotive Wire Harnesses for Engine Rooms

Automotive wire harnesses are the most essential parts for the engine rooms. In the engine room of a vehicle there is extreme heat which can melt the harnesses and the wires. And the friction and the shaking of the materials can make it even weaker. And that is where these high quality harnesses are the best option. These harnesses are protected with the high quality materials which let the inner core of the harness last for a long time. Automotive Wire Harnesses prevent the sudden stops of the vehicles by protecting the harness from melt down. The harness supplies the right signals and the accurate power to the system. It connects the control panel to the engine and smartly handles the process to run the whole system. You can easily install the harness because of its easy to use features. There are many harness types for the different types of systems. The harnesses are flexible enough to easily fit in the exact position. How Heat Affects the Engine The engine makes heat like a small fire burning bright inside a metal box. Metal parts rub against each other, creating friction. Oil flows through narrow spaces and gets hotter over time. Fans blow air to cool things down, but a lot of the heat still stays inside. The wires are exposed to these hot parts every single day. Without heat-safe protection, they can become soft, melt, or even emit smoke. A spark might jump the wrong way, potentially causing significant damage or even igniting a fire. A high‑temp wrap or sleeve acts like a shield, keeping the wires cool and safe. With the correct type of heat‑proof wrap, the cables stay firm and strong, even when the engine runs like a stove on a long drive. This helps the car...

Mehr lesen "Waterproof Automotive Wire Harnesses for Outdoor Vehicles

Get the automotive wire harnesses that are built for the off road vehicles. These harnesses are made accurately with high quality materials. These harnesses are best for the vehicles that are built with the heavy duty materials. To connect all the vehicle parts these harnesses supply proper power and the signals to the engine. The harnesses are made with the best quality materials. The core of the harnesses are made with the coppers and the whole harness is covered to shield the harness. The leakfree sealing of the harness makes it durable and lets it last for a long time. Automotive Wire Harnesses are the best choice for outdoor vehicles. Built for Rough Roads and Harsh Weather For the heavy duty vehicle power supply the power system needs the exact power supplying harnesses. A waterproof automotive wire harnesses makes sure the vehicle engine gets the most accurate type of power and signal source without any issues. The outer shield protects the inner core of the harness from heat and other harmful elements. The flexibility of the harness makes sure the harness is easy to bend and adjust so you can use it in many sections. Each harness offers the best features for your vehicles. Every time you get the smoothest performances from these harnesses. Importances of Waterproof Automotive Wire Harnesses A custom automotive wiring harness is not just wires tied together. It's like a safe coat that keeps your power lines safe from water, heat, and damage. Even a small leak can cause your lights to stop working, damage your tools, or weaken your engine. That is why the car wire kit wraps tightly to prevent leaks and keep power running safely at all times. Main Benefits: Keeps your power working even on wet or muddy roads. Stops short...

Mehr lesen "Industrial Custom Wire Harness for Automation Sectors

Modern machines utilize numerous wires to function. These custom wire harnesses carry power and signals that enable each part of a system to communicate with one another. Custom cable and wire harness products make sure everything stays safe, clean, and connected. They are essential in factories, as well as in robots and all automated machines. Let’s learn how these special cables keep industries running smoothly and efficiently. These harnesses are built for the automation sectors where the accuracy and the durability both are essential. Basics of Custom Wire Harness A custom electrical wire harness is a bundle of wires tied together. These wires send power or data between different parts of a machine. They are made to fit a machine’s exact shape and needs. A custom wire harness manufacturer carefully crafts each harness to ensure that no wire is wasted or misplaced. The cables are covered and arranged to stay safe from heat, pulling, and dirt. Some harnesses utilize special colors, connectors, or coatings to enhance their strength and facilitate easier repair. This helps the system remain stable and run continuously without interruption. In automation, every wire matters because a single loose wire can prevent a machine from functioning properly. Why Automation Needs Custom Wire Harnesses Automation machines work non-stop. If wires are messy or weak, they can break, causing production to stop. That’s why a custom wiring harness assembly is used in most factories. These harnesses keep wiring neat, strong, and easy to find. They also save time when repairing or upgrading parts. Main Benefits: Neat and easy-to-check wiring Quick to install and fix Built with strong, heat-safe parts Made to fit each unique machine A well-designed wire enables machines to run longer with fewer problems. For busy factories, this means more work is done and less...

Mehr lesen "Plug-Ready Custom Wire Harness for OEM Integration

When you design or build something new, such as a car, a machine, or even a household tool, wiring is a significant part of the job. A custom wire harness keeps all the wires neat, safe, and simple to use. It ensures that every cable remains in the correct position and functions appropriately. Without it, wires can get messy, tangled, or even unsafe. That is why, at QL-Custom Technology Ltd., we manufacture strong, flexible, and easy-to-install custom wire harnesses that are ready to plug in. Every harness is made to match your design perfectly. It helps your work look clean, run smoothly, and last much longer. These harnesses help builders, engineers, and repair experts save time while keeping things neat and easy. Beneficial Sites of Plug-Ready Custom Wire Harnesses A plug-ready custom wiring harness makes setup simple, fast, and smooth. You don’t have to twist or tape wires, and you don’t need to guess which wire goes where. You just plug it in, and it starts working right away. This means fewer mistakes, less stress, and more time to focus on other parts of the job. Each harness keeps your wiring clean and protects your equipment from shorts or loose connections. If you build cars, repair machines, or run a factory, a trusted custom wire harness supplier like QL-Custom Technology Ltd. can make a huge difference. Their harnesses are designed for real jobs and built to withstand the rigors of daily use. Each piece undergoes rigorous testing to ensure it lasts long, remains safe, and performs well even under stress. Benefits of Custom Wire Harnesses Using custom wiring harnesses brings many great benefits that help both small and large projects: All wires stay clean, straight, and easy to follow Much less chance of wiring mistakes or short circuits Easier and...

Mehr lesen "Get Automotive Wire Harnesses made for Long-Term Use

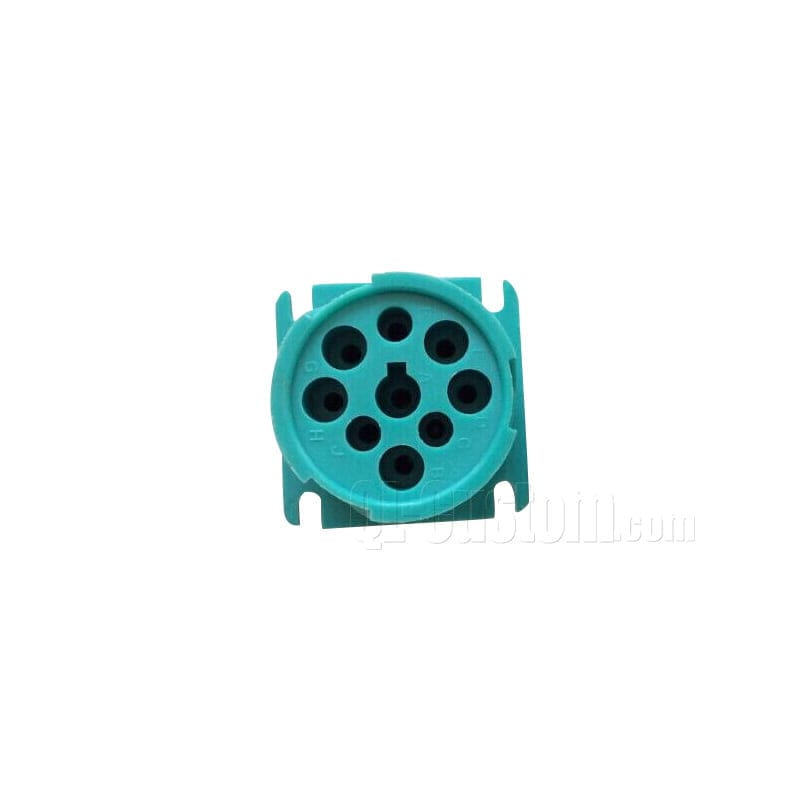

Automotive harnesses are used to keep the vehicle in a great position. Our automotive wire harnesses are designed to keep your automotive system safe. The harnesses are designed and sealed with proper care. These harnesses supply the essential power to the engine. These harnesses are especially made to connect the sensors and other body parts of the vehicles together. You get the least manual work and less issues with our harness. We designed the harness carefully and manufactured them with the materials that are high quality. With our harnesses you get the best services when you install them on your vehicle. The durability and the flexibility ensures that the harness is suitable to use on various types of sectors. We probably check each harness to ensure the durability and long term use. Made to Last and Keep You Safe If you want automotive wire harnesses that stay strong for many years, the automotive harness wire from QL-Custom Technology Ltd. is the best pick. Each wire is designed to withstand rough roads, high temperatures, rain, and extended driving without issue. These wires help cars and trucks run safely by sending power smoothly and steadily. They are made from tough, safe materials that stop breaking, melting, or shorting. Their design also helps prevent signal loss, so your car runs smoother, safer, and firmer every day. You can count on these wires to continue working, even after years of use in harsh environments. Custom OBDII and J1939 Connector Cables These automotive wire harnesses are carefully crafted to ensure a perfect fit and reliable performance every time. They are simple to plug in, easy to use, and designed to last much longer than standard cables. You can choose from various sizes, pin styles, and shapes to find the perfect one for your setup....

Mehr lesen "EV-System mit intelligenten Kfz-Kabelbäumen aufrüsten

We design the most advanced and smart automotive wire harnesses for your EV system which delivers the most efficiency. These harnesses are manufactured with the materials that are high quality. The materials are tightly attached to ensure that the harmful elements do not harm the harness core. The harness keeps the engine running smooth and the EV motor in a great position. These harnesses are easy to install. You receive the best performances and exact signals each time with the wire harnesses. These harnesses are great for supplying the power and the signals easily. EVs need the exact signals for better driving and the smart key features and these harnesses are the best option for these projects. Automotive harnesses let you save power. Smart Automotive Wire Harnesses: for EV Systems Evs connect all the essential parts of the vehicle system. The wires must be strong and flexible for ease to use. Premium quality automotive wire harnesses let the control panel supply power and signals easily. The smart design lets you set up the harness easily. The harness is built to produce the most accurate type signals to run the EV system. Importance of Upgrading Your EV System A smart automotive wire harness assembly is the best way to connect the whole EV system smartly. The wires are designed and manufactured correctly to handle the transferring job easily and carefully. The harnesses are made to resist the over heat and extreme quality pressure.The parts of the EV last for a long time with these harnesses. You always have the least repair issues with the harness. With these harnesses your EV runs smoothly and perfectly without error. Benefits: Better power flow through the wires Lower repair costs Safer design that stops short circuits A clearer signal between the parts Longer battery...

Mehr lesen "Buy Affordable Custom Wire Harness with Top-Grade Quality

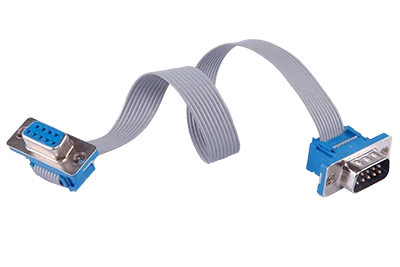

Our affordable harnesses are made with durable quality materials which makes them most suitable to use for your projects. You can use them for many sectors. The Custom Wire Harnesses are carefully and toughly checked. We use the wires in the harness that are the best quality and built with the best materials. These harnesses handle extra heat and the tough weather without getting damaged. Our harnesses are made to offer the best services to your machines. We also offer you the best and affordable price for the top quality harnesses. With our harnesses you get the best performances at an affordable price. Also you can customize the harness according to your project, we produce you the huge customizable option for your wire harness. Our team is well experienced and friendly to handle your project professionally. Buy from Reliable Custom Wire Harness Assembly QL-Custom Technology Ltd. is the top rated place online for purchasing the wire harnesses. There are various options available for the custom wire harness assemblies and cable assemblies, as well as wire harnesses. These Custom Wire Harnesses are used in various sectors for many types of projects. Every product you receive from QL -Custom is the most accurate and best quality. To produce the top grade products there are multiple teams assembled for each sector. Every harness is made with the best quality materials to last for a long time. Features of Our Custom Wire Harness Assembly Manufactured with the most durable materials These harnesses undergo tough tests to ensure the safety Easy to use for its smart shape and size Fulfills every needs of the project The price for the harness is affordable and fair. Exactly build to resist the tough weathers Follows every rules to keep the quality good Flat Ribbon Cable: Flexible and...

Mehr lesen "Order Premium Custom Wire Harnesses for Your Needs

For the best service quality you need the advanced type and durable harnesses. Our custom wire harnesses are carefully designed with the premium quality materials that undergo all the tests to ensure your machines safety. The materials used in the harness are durable enough to resist the harmful elements that can cause damage to the harness core. These harnesses are used in many sectors to provide the exact signals. We follow each detail given by you and deliver your the most accurate type of harness that fit your project needs. The wires and core of the harness remain clean and safe because of the flexible and hard cover. We build each part separately to ensure issueless connections. The harness is easy to bend for its flexible core and cover materials. You can use these harnesses in various types of sectors to keep the power and signal flow at an exact level. Get the Best Harnesses from Trusted Experts For the exact type of performances and the best quality you require trusted custom wire harness manufacturers. At QL-Custom Technology Ltd., we offer you the products that are made with the high quality materials and durable to use. We carefully follow each detail given by you for your project to offer the best harness that exactly fits your needs. We have long term experience and leading productivity in this section. We carefully design each part and combine them and make sure the quality of the harness is best. Advantages of Custom Wire Harnesses Custom wire harnesses assemblies help make your work easier and safer. They keep your wires neat and protect them from heat, dirt, and damage. They can be used in cars, electronics, and even at home. A custom harness ensures that each wire is placed precisely where it belongs, resulting...

Mehr lesen "Premium Automotive Wire Harnesses for Long-Lasting Quality

Premium automotive wire harnesses utilize top-quality parts and rigorous quality checks to ensure wires are kept safe and secure. They stop working due to wear, heat damage, water damage, and loose connections over time. Each one is built to match the car, the power needs, and the engine space, so nothing is wasted. This makes driving safer and smoother, with fewer breakdowns. Strong and Simple Power Connections A wiring harness in a car is like the veins in your body. It carries power and information everywhere to the lights, sensors, and dashboard. Without it, the car won’t run. At QL-Custom Technology Ltd., we design and manufacture custom automotive wiring harness systems that are robust, safe, and user-friendly. Our J1939 connectors help your car or truck operate smoothly by ensuring power and signals flow smoothly. Each harness is designed to withstand long trips, adverse weather conditions, and rough terrain. Automotive Wire Harnesses: Made for Every Vehicle Every car, truck, and heavy machine is different. That’s why each harness vehicle system we manufacture is carefully designed. Our truck wire harness and wiring harness for car engine fit perfectly and are easy to install. We test them to make sure they are strong and safe. These automotive wire harnesses can withstand heat, shaking, and moisture. No matter where you drive on city roads or in muddy areas your wiring stays safe. At QL-Custom, we focus on long life, easy use, and secure power flow. Why Pick a Custom Wire Harness A good electrical wire harness saves time and money. It helps your car run better and keeps it safe. QL-Custom automotive wire harnesses are simple to install and last for many years. Each automotive wire harness assembly stops power loss and short circuits. It also makes repairs easier in the future. Our automotive...

Mehr lesen "