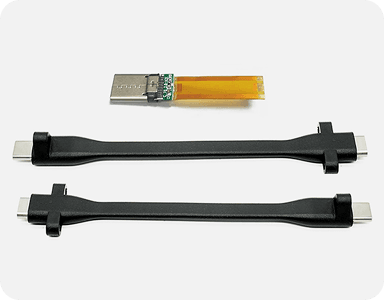

FFC cable VS FPC cables

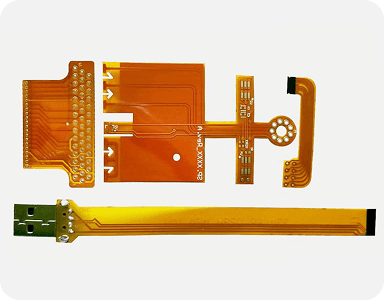

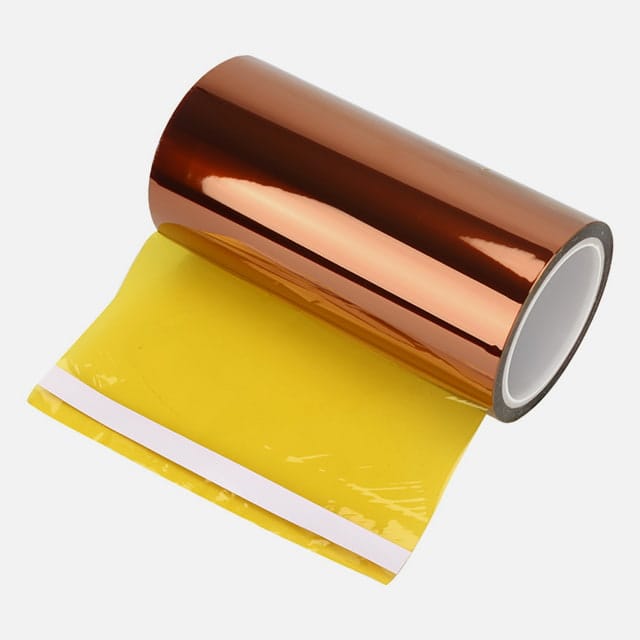

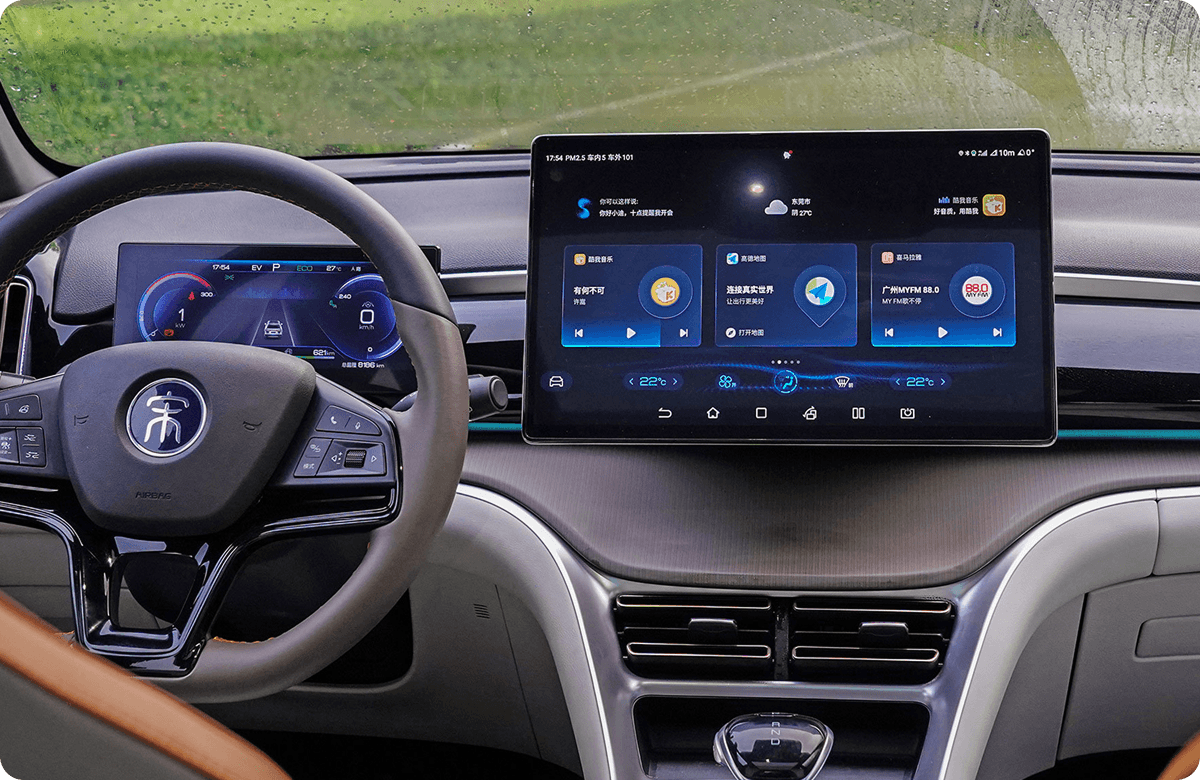

The FPC FFC molded cable assembly and the FFC connector both use very thin plastic bases. An FFC is a flat ribbon of parallel copper wires attached to plastic sheets. Use it for simple, straight connections. A flexible printed circuit (FPC) cable is made up of complex circuits that are etched onto a thin sheet of polyimide with copper traces. A flexible printed circuit (FPC) is like a small printed circuit board (PCB) on a flexible film. An FFC, on the other hand, is just a simple set of point-to-point connections. FFC cables are cheap, so printers and displays often use them. FPCs make it possible to have multilayer circuits in small spaces, but they cost more. Both can be changed, but FPC cables are more flexible and can support more features on mobile devices.