Try Out Custom Wire Harness Builds for Tough Power Routes

By hdhhd shhsbbs / 2025年11月24日

Custom power pathways must stay strong even when they are under a lot of stress, like when they have to carry a lot of weight, work with hot equipment, or fit into a small space. A lot of teams look for custom wire harness makers who can make sure the wires are neat and safe, even when they have to go around tight corners or fit into tight spaces.

These companies check every wire and junction to make sure that the electricity can flow freely. A well-made custom wire harness assembly is necessary to keep power steady, reduce noise, and stop wires from coming loose. The coordinated work of each part makes sure that the system is safe as a whole.

Necessity of Custom Builds for Various Sector

Custom wire constructions make it possible for equipment, cars, and new tools to work safely and well. The device’s design determines the shape of each wire, and those wires need to be able to handle the heat from the device and the space they have to travel through. The wires in 定制线束 are made to withstand stress, twisting, and bending. This will make the wires last longer and have fewer places where they can break.

Brands want wires that are clean, tight, and won’t fray or break. They use custom cable and wire harnesses because they can fit into tight spaces and places that are hard to reach. Strong wires, well-organised wrappings, and secure crimps are all important for keeping everything in place. The route is easy to follow and well-marked when maintenance is needed.

The company that makes the custom wire harness is able to test each part. We test plug locks, heat strength, pull strength, and bends, among other things. These tests make sure that the harness can work safely in hot, dusty, or tight spaces. With each step, the harness becomes more trustworthy and dependable.

Categories that Require these Builds

- Electric cars, mobility devices, and automotive networks

- The heat and dust make it more likely that you’ll need to use heavy tools.

- Keeping the wires on lab equipment neat and tidy

- Smart home hubs and Internet of Things devices

- Huge electrical panels and racks

Custom wire harness manufacturing helps teams make devices that are safer and easier to use. The wires will be safe, the gadget will work well for a long time, and electricity will flow more easily with a strong harness.

Advantages of Custom Wire Harness

- Quick and easy repairs

- Clearly laid out and easy to get around

- Connections that are quiet and work well

- Getting through hard times

- Less time spent staying away from dust or heat

- Works well in tight spaces

- Doesn’t break down at high temperatures

- Little mess from internal wiring

Now that you know about these benefits, you can choose the best 定制线束 manufacturer for your project.

Suggested Custom Wire Harness Choices

Custom XLR Cable

XLR wires are used in sound equipment, cameras, audio boards, and stage lighting. These cables need to keep their sound quality and strength. A custom wire harness maker in China might make:

- Audio transmission without interference

- Plugs with three or five pins that last a long time

- Strong exteriors for protection

- Works quietly

- Wraps that are always the same shape

These cords make the sound equipment, lights, and microphones work better during long performances.

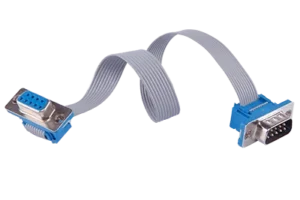

扁平带状电缆

A flat ribbon cable is a thin, flexible, and bendable cable. Many tools use them when space is limited. You can often find them in chips, boards, and testers. They are also useful for making custom automotive wire harnesses.

好处

- Its thin profile makes it easy to fit through small openings.

- Soft curves that don’t break

- Paths for organised cables

- Very easy to put in and take out.

- Small and easy to carry.

- Great for linking boards

These wires keep the inside of a car neat and easy to fix.

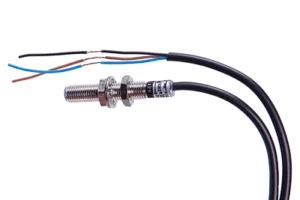

Sensor Cable

Sensor wires can read a lot of things, like light, gas, speed, temperature, and more. Tools must stay still even when they are moving or shaking.

- Strong barrier to block sound

- Data that is clear

- Lasts even in tough conditions

- Results that are always correct in tough situations

- A lot of different types of plugs to fit a lot of different tools

- Minimalist design for tough spots

These wires can be used in lab, test, and field tool wire harnesses.

Molded SR Cable

"(《世界人权宣言》) strain relief (SR) that is built into the plug end protects the wire from damage that can happen when it bends.

- Longer-lasting

- Moulded exterior that lasts

- Protection from stress

- Good grip for shaking tools

This type is often used in 定制线束 setups for cars because the wires are more likely to bend and shake.

Extra Topics to Focus on with Custom Wire Harness

Build Flow Map

- Good stores follow a simple plan:

- Look at the heat and mass.

- Pick the right size of wire

- Choose the right plug

- Find out how strong the crimps are

- Check for twists and curves

- Check how hot and tense it is.

- Look over everything one last time.

This is the best way to make custom wire harnesses for heavy and long-term use.

Key Build Areas

| Topic | Notes |

| Load Test | Checks flow and heat |

| Fit Test | Tests bends and space fit |

| Plug Check | Tests plug lock strength |

| Wrap Check | Makes sure wraps stay neat |

| Life Scan | Checks long‑term wear |

Pick the Right Custom Wire Harness for Your Needs

QL-Custom Technology Ltd. builds custom homes that are strong, clean, and safe. By testing and checking every item and wire, they help manufacturers make harnesses that can handle tough situations. Call them if you need a custom wire harness. They are a trustworthy group. Their wide range of high-quality products is designed to meet the needs of your project. They will also give you the best and most polite help.

常见问题

How strong are custom wire harnesses?

Yes. These harnesses are great for tough jobs because they are well-made and well-wrapped. They are tough and can handle rough ground, long trips, and strong vibrations. The harness keeps the cables level, safe, and in place, even when working in tight spaces or close to heavy machinery. This makes sure that everything works as it should.

Can I pick the kind of wire I want?

Yes. You can change a lot of little things about the harness, like its size, wrap style, colour, plugs, and more, to make sure it’s perfect for your job. You can choose from basic colours, soft wrapping, or strong plugs to make it easy to tell what each wire is for. This makes the harness easier to use, read, and fix.

Would a custom harness work in a small space?

Yes. These harnesses can be shaped, curved, and scaled to fit in tight spaces or areas with strange shapes. They can fit into small spaces where stray wires might get stuck. The setup is safe and easy to control because the harness doesn’t move or come loose once it’s fastened.

So, how many times do you think they will be used?

They last a long time because they are made with strong materials, wrapped neatly, and built with care. A strong harness can handle years of use, heat, and shaking. The harness is in great shape because it has clean lines, tight joints, and strong guards. This makes the system more stable, safe, and easy to keep up with.

Can they handle a lot of energy?

Yes. Their design can handle a range of power levels, from low to medium. The power stays steady, safe, and calm because each wire is chosen to handle the right load. This helps keep the system safe by stopping heat from building up, even when the job needs a lot of power.

人们还会问

Do they work with machines?

Yes. They are necessary for machines to work well and reliably. The wires don’t rub against each other or move around, so the device gets clean power and signals that don’t stop. This means that the machine can run for longer periods of time without breaking down or needing repairs.

Are the times it takes to build shorter?

Yes. Using them cuts down on construction time by a lot. Simply lay the harness down and connect the ends; the wires are already grouped and ready to use. It makes the whole thing easier and saves a lot of time.

Can I add clips or plugs?

Yes. You can add clips, plugs, locks, and other small parts to make it work for you. These parts make the harness fit better, stay in place, and connect more quickly. They make the work easier and help keep things in order.

Are they flexible enough to fit into tight spaces?

Yes. They are very flexible and can be bent, twisted, and curled to fit into many different spaces. The wrap keeps the wires from getting pulled or rubbed, so they stay in good shape even when the path is narrow.

Are they safe outside?

Yes, but only in some situations. These parts keep the harness safe from the weather. This keeps the wires dry and clean, which keeps the harness strong even when the weather changes.

Can they stop breaks?

Yes. They protect wires from damage caused by vibrations, pulls, and rubs. The wires stay in place because they are neatly wrapped and in the right shape. Because of this, the whole system can run more smoothly and efficiently.

Is it easy to change them?

Yes. They often use simple paths, clean layouts, and clear signs. This makes it easier to figure out where each part goes. It’s easy to change a harness because you can see what to do right away.

Can I choose my own colours?

Yes. You can use different colours to show which wires are which. This makes it easy to find, read, and test every line of code. It makes it easy and quick to test, fix bugs, and build new things.

Can you use them in cars?

Yes. Some cars use special harnesses to protect wires from extreme temperatures, vibrations, and tight spaces. These harnesses not only keep everyone safe, but they also keep the car running smoothly by stopping rubbing.

Could they be made quickly?

Yes. Many shops can put them together quickly because they use parts that are easy to find and procedures that are easy to follow. This means you can finish your work without having to wait long for the harness.

附图的定制线束