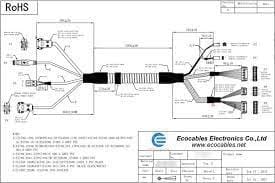

为工业制造项目定制线束

By hdhhd shhsbbs / 2025年12月1日

Custom wire harnesses are essential for the efficient operation of machines of all sizes in busy environments. These harnesses keep wires safe, stable, and away from heat, dust, sharp edges, and rough parts. They do this by bundling several stray wires into one clean thread. When the cables are neatly stored, the whole area becomes quieter, less cluttered, and safer for everyone who works there.

These harnesses help keep things tidy and let teams move around more easily. These harnesses fit so well that it’s usually easy to put them on, even in wide open spaces. Many teams use custom wire harnesses when daily strength and readiness are very important.

The Vital Uses of Custom Wire Harnesses

A good 定制线束 keeps all the wires in one place so they don’t slide, twist, or scrape against each other. This makes the work line safer, lowers the risk of accidents, and stops tools from breaking down when you least expect it. When the cables are neatly organized, the machine runs more smoothly and doesn’t stop as often. With custom wire harness assembly services, you build the set with your own tools, making sure that every wire, wrap, plug, tube, and clip fits your project perfectly.

This way, the wires will last longer and be better protected, even after long shifts. Many teams trust custom wire harness manufacturers because they make high-quality products that last a long time and have a lot of thought put into their designs. Workers can do more in less time, with less stress on their tools, and with less effort overall when they use custom harnesses. For big businesses, it’s also important that they help teams stay in line with strict safety rules.

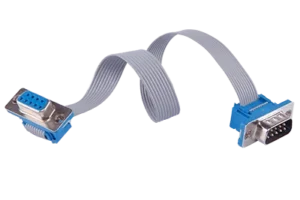

Flat Ribbon Cable: Soft Shape for Tight Spots

扁平带状电缆 is easy to work with in tight spaces with walls and other obstacles nearby. This cable can easily go through long, narrow holes because it is flat, smooth, and easy to bend. Flat ribbon cable keeps the signal flow strong and steady in small test tools, skinny lab units, small boxes, and control panels. The cable’s smooth, even shape reduces the load on the wire route, so the wires stay in good shape even after a lot of use. The system stays cool and helps with heat issues because it is thin and light. It works best in tight spaces, like thin racks, narrow device pathways, and small buildings, because big cables won’t fit.

Why You Will Like It

- Simple design for small spaces

- Bending that is smooth and quick

- Proper look

- Quickly and easily set up links

- This is great for designs that are clean.

This cable works well with custom cable and wire harnesses to make wire routes that are easy to follow during complicated projects. It’s a great choice for groups that want simple, clear paths. Many builders turn to QL-Custom Technology Ltd. for help with making flat ribbon drawings for new machines or for work that needs to be done on existing ones.

Molded SR Cable: Firm Grip and Long Life

Molded SR cables stop pulling, twisting, and bending at the point of strain. The molded head keeps the wire core from getting too much load by protecting the junction from tension. This makes the wire last longer and less likely to break. With its help, the wire is less likely to be damaged by heat waves, drops, sharp twists, and vibrations. Molded SR cables are great for tools that push, twist, move, press, or tap a lot in tough conditions. The molded end keeps dust, dirt, scraps, and fine grit from getting into the open joints and damaging the wire. The link is strong and long-lasting, able to handle endless cycles.

Key Points

- Strong shield

- Long-lasting even after a lot of use

- Doesn’t change with temperature

- Design of plugs that is safe and clean

- Easily move tools

These cables will work great for any custom wire harness assembly ideas that need steady power. A custom wire harness design and quote can help you fit these cables into your tool’s design, wire route, and workflow. Many teams depend on these wires for both light and heavy-duty equipment.

Overmolded Cables: Sealed for Tough Jobs

包覆成型电缆 are the best choice for tough, dusty, abrasive, or rainy conditions. The strong cable seal helps keep out heat, dirt, oil, mud, and water. The signal and power flow stay clear even when the tool is used to its full potential. Many teams that work with heavy machinery, test rooms, outdoor areas, and factory floors trust overmolded cables because they have a secure grip and a steady flow. The block seal not only keeps the cable from slipping, but it also makes drops and bangs less painful. Overmolded cables have a lot of benefits, such as less wear and tear, less stress on tools, and the ability to work for long periods of time.

Good for Many Fields

- Tools and vehicles used on the plant floor

- Workstations and tools for analysis

- High-load units that run all the time

- Instruments for the engine, power, drive, and command

- Adventure clothes and places that get a lot of dust

These parts work well with China custom wire harness designs and help create strong custom wire harness manufacturing processes for places that need steady power for a long time.

Custom OBDII: Precise Data for Fast Check

Custom OBD-II connections make it easier for auto teams to scan truck and car data with less noise. These cables work with modern car diagnostic tools and give accurate results even when the shop is busy. The strong plug will keep the signal from getting lost. This makes it easier to find problems early on and speeds up the process of checking. This makes the workflow better and saves test sites time.

Why Use Custom OBDII

- A steady stream of data that isn’t cluttered

- A small, safe plug

- Works well in rooms where cars are put together

- Works with many different kinds of cars

- Easy to move and store

Custom wire harness assembly services could be very beneficial for auto teams that use their OBDII equipment for long hours, quick testing, and safe operation.

Custom Harness Use in Key Fields

Medical Tools

A 定制线束 made for medical instruments may help you hold, clean, and protect your lab equipment better. These harnesses are strong and will last a long time, even when they are exposed to high temperatures, long shifts, and sharp turns. They hold on gently but firmly so that no wires come loose or fray. In medical and laboratory settings, making wire routes easier to understand and organizing them can help reduce stress and mess. Also, these harnesses help keep fragile tools safe and support gadgets that are important for saving lives and need to be on all the time. They are helpful for long medical shifts because they make things safer, quieter, and even help with power distribution.

Parts of a Robot

Thanks to a 定制线束 for robotics, robot arms can turn, lift, pivot, and slide without hurting the wires inside. These harnesses bend a lot every day while keeping all the connections safe. They make it possible for robot lines to move smoothly and all the time. With well-organized wire routes, robots can work faster, safer, and without making mistakes. This is good for the whole line because it helps teams meet their tight deadlines.

Fast View of Key Cable Types

| Cable Type | 最佳用途 | Key Gain |

| Flat Ribbon | Tight space | Bend ease |

| 模制 SR | Stress zones | Long life |

| Overmolded | Tough sites | Seal and shield |

| 定制 OBDII | Auto test | Clear data |

Partner with QL-Custom Technology Ltd.

QL-Custom Technology Ltd. can help you with all of your custom wire harness manufacturing needs, no matter how big or small your project is. They make each part with care and creativity. You get clear instructions, easy assembly, and a snug fit. They have people on staff who can help you find the right plugs, wraps, clips, and seals for your gear. When you buy a wire harness design and price, you may want to think about your site’s needs, the tool form, and the speed at which you work. They want you to be able to make pathways that last and are safe.

Custom harnesses make the workplace calmer, safer, and easier to work in. With the right harness, machines can run more smoothly and without making mistakes. You can get in touch with QL-bespoke Technology Ltd. to have your next custom plan designed, built, and ready for use in the field.

常见问题

Are custom wire harnesses safe?

Yes, they are very safe because they keep cords taut, secure, and out of harm’s way. When wires stay in a straight line, there is no sparking, overheating, or scraping of wires by moving parts. A harness keeps the wires in place like a gentle hand. It adds an extra layer of protection and stops them from shaking or hitting things. This lowers the chances of machines breaking down or wires breaking. The wires stay tight and don’t move, no matter how long the machine runs.

How many steps are there to make one?

Because each harness is made to fit a specific need, the timing could be very different. A simple harness could take just a few days to make, while a more complicated one could take weeks. The constructor is in charge of carefully choosing, measuring, cutting, arranging, and wrapping the wires. For the harness to work properly for a long time, each wire must be in the right place. This careful process is necessary to keep the machine safe and strong.

What are some ways I can change the types of wire?

You get to choose a lot of the parts that make up your harness. You can change the size of the wire, the thickness or softness of the wrap, the plugs you use, and even the small parts that hold the wires in place. Depending on your needs, you can use thin wires for delicate tasks, thick wires for strong ones, and flexible or rigid wraps. You can choose from a range of plugs or clips that hold things in place and stay there. If you follow these steps, you might be able to find a harness that works well for you.

Do custom wire harnesses cost more?

They might cost more up front, but in the long run, they will save you a lot of money. A harness that is well-organized and safe makes it less likely for wires to break. This makes the machine last longer and costs less to maintain. When the wires stay where they should be, the equipment works better and needs fewer repairs. Even though the first cost seems high, the harness is a smart and safe buy.

Are they safe to use in dirty or otherwise hard-to-reach places?

Yes, they can be built to work in very harsh conditions. They can handle very high or low temperatures, high or low humidity, wetness, dust, dirt, and rough handling. You can get wraps that keep water out, adhesives that don’t melt in the heat, and coverings that keep dust out. This means that the harness will stay safe and secure in any situation, no matter how messy or complicated it is.

人们还会问

Will their old machines work with them?

They can be made to fit old or strange machines that might be hard to find replacement parts for. A new harness fixes the machines by replacing the old, worn-out wires with new ones. You don’t need the whole machine; just change the connectors to get it going again.

Can you trust them to move tools?

Yes. They make sure the wires are tight so they don’t pull or break when the instrument shakes or moves. This keeps the cables from getting damaged and makes sure that all the moving parts work smoothly. It keeps the machine safe no matter what, whether it’s moving, twisting, or vibrating.

Can these things cool down wires?

They help lower the temperature by keeping the wires apart so they don’t rub or push against each other. There is space for each wire to stay cool. This stops the wires from wearing out too quickly and makes the machine work better.

Are there any limits to how many wires they can hold?

Yes, they can hold both short and long bundles of cables. The harness keeps things in order, no matter how big they are. This makes it much easier to handle large groups of wires.

Can you use them outside?

Yes. You can make them strong enough to stand up to snow, dirt, wind, rain, and sun. With the right wraps and coverings, the harness can be protected from the weather all year long.

Could they help save space?

Yes. In tight spaces, they let cables connect in a neat single line, which saves valuable floor space. This makes the place look clear, clean, and safe to work in.

Is it easy to test with them?

Yes. It’s easy to test the wires when you know they’re all in the right places. Because of this, workers can quickly find problems and save time.

Are there cables that are the same color?

Yes. You could use simple, bright colors to make each wire stand out. It’s easier to check and fix things when wires can be quickly found.

Do they work for long cable runs?

Yes. They keep long wires from sagging, twisting, or bending by keeping them in place tightly. This is how long cable paths stay clean, safe, and strong.

Can custom wire harnesses help cut down on noise?

Yes. They stop the wires from moving around, which helps reduce shaking and buzzing. The equipment should then work well, which will make the workplace calmer and more peaceful.

附图的定制线束