Custom Wire Harness: Exact Made for High-Reliability Sectors

By hdhhd shhsbbs / 2025年9月7日

Custom wire harnesses are made for the tasks that need to be accurate each time. These harnesses are made for tough places. These harnesses can resist the high heat and difficult weather. To make this harness the high quality materials are used to last long. The harnesses go through the vital tests that improve these are safe for the high-reliability sectors. These are used in many sectors to supply power and signals smoothly. And for accurate data transfer these harnesses are essential.

Custom Wire Harness and Uses

This is an innovative system built to carry power and signals safely and neatly. The harness gathers many cables into one clean unit that is easier to use and safer to place in cars, planes, and machines. In tough fields like cars, planes, health, and defense, even one minor fault can cause a considerable risk. That is why they need a trusted custom wire harness supplier. A harness must last through heat, cold, shake, and stress. It must be tested again and again to be sure it is safe. Skilled custom wire harness manufacturers offer wire harness assembly services with strict checks at each step. Without strong harnesses, most modern machines would fail to work.

High-Reliability Sectors Require Custom Harness

Simple harnesses may work for light jobs, but hard fields need more care. They need custom cables harnesses made for exact tasks. If a car has weak wires, it may stop on the road. A plane with bad wiring may put many lives at risk. A medical tool with poor cables may fail at the worst time. A custom harness built with high-grade parts can take heat, cold, shock, and shake. It saves space and makes installs fast and smooth. It adds more safety to the whole system. This is why top brands never trust low-grade parts.

Custom Wire Harness: Benefits in High-Reliability Sectors

- Safer, less chance of fire or short circuits

- Works steadily in heat, cold, or dust

- Neat design saves time and space

- Lasts longer with less wear

- Fewer repairs and less downtime

- Easier to swap or fix in the field

Key Sectors That Use Custom Wire Harness

Aerospace

Planes and spacecraft face the harshest stress. The harness must work under heat, cold, and extreme conditions. A weak harness may risk lives and cost millions. That is why a custom wire harness assembly is vital in aerospace. Each part is wrapped, shielded, and tested to flight rules. The harness is light to cut weight but strong enough to last. It must work for many years, even in space where service is not easy.

Automotive

Modern cars have sensors, lights, alarms, and media units. A custom wiring harness for cars joins all these parts in one neat bundle. Car wire harness manufacturers make harnesses that last for years and save power. They make cars safer and more fuel-smart. Many also use custom car wiring for upgrades, new lights, or sound systems. A good harness ensures the car runs smoothly and safely on all roads.

Medical

Health, safety, and trust come first. A fault in wires can put a life at risk. Custom wire harness manufacturing ensures medical cables are clean, safe, and tested many times. From scans to monitors to life support, all need steady wires. A strong harness gives doctors trust that tools will not stop mid-use. This also gives patients peace of mind when they rely on care tools.

Military and Defense

Defense gear is used in deserts, seas, snow, and mountains. Wires must stay strong in all places. Wire harness manufacturers for defense use strong shields, safe plugs, and covers that can take battle stress. Each harness is tested for war use. A good harness keeps troops safe and gear working even during the most challenging times.

Manufacturing Process of Custom Wire Harness

- Design: The first step is design. The team works with the client, studies the task, and completes the plan. Every wire, plug, and shield is marked.

- Material Selection: Strong parts are key. Wires, plugs, and covers are picked with care. All parts must pass safety rules and laws.

- Prototyping: A test sample is built. It is checked for fit and use. If it does not work well, changes are made until it is right.

- Assembly: The harness is built in a clean place. Tools like presses and crimpers link wires with care. Each step is checked for high quality.

- Testing: Every harness is tested. Flow, heat, bend, and stress are all checked. This shows if it is safe for real use in the field.

- Delivery: Once tests are passed, the harness is packed and shipped safely to the client.

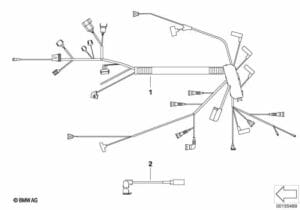

Custom Wire Harness for High-Reliability Sectors

Custom OBDII Harness

OBDII means On-Board Diagnostics II. It is a port that reads car data. A custom wiring harness for cars with OBDII links the car brain to scan tools. This makes fixes fast, simple, and straightforward.

Benefits of Custom OBDII Harness

- Easy plug and play

- Strong and neat build

- Quick data read

- Long-life plugs

- Fits many car types

QL-Custom Technology Ltd. makes custom OBDII harnesses with great care. Each unit is tested for long-term use. They are trusted by car shops all over the world.

Overmolded Cables

Overmolded cables are wires wrapped with molded plastic. This makes them strong, sealed, and easy to bend. They work well where dust, heat, or water can harm. Custom wire harness manufacturers use them to make harnesses that last longer in tough spots.

Benefits of Overmolded Cables

- Sealed from dirt and water

- Stops bend and shock damage

- Fits nicely in a tight space

- Lasts longer in hard use

- Has a neat, clean look

QL-Custom Technology Ltd. makes overmolded car cables, tools, and health gear cables. They are known for strong and safe builds.

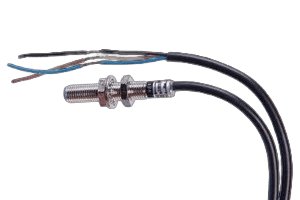

Omron Switch Cable Relief

Cable relief keeps wires from bending too much at joints. Too much bending can snap a wire. The Omron switch cable relief keeps joints safe and strong. It adds more years to the harness.

Benefits of Omron Switch Cable Relief

- Stops cracks at plugs

- Makes cables last longer

- Works in many tools and gear

- Low cost but significant savings in repair

QL-Custom Technology Ltd. sells Omron switch cable relief harnesses. They fit plant gear, innovative tools, and tech units.

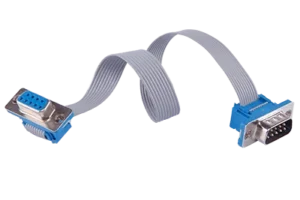

Flat Ribbon Cable

A flat ribbon cable is a wide strip of wires lined side by side. It looks like a neat ribbon. It is used in PCs, printers, and boards. It makes neat and quick links inside tools.

Benefits of Flat Ribbon Cable

- Easy to fold in a small space

- Saves space in tight gear

- Gives a clean, neat look

- Fast link between parts

- Works with many kinds of tools

QL-Custom Technology Ltd. builds flat ribbon cables in many sizes and types. They can be short, long, thin, or broad as needed.

Features of QL-Custom Technology Ltd.

| Feature | Benefit |

| Custom Design | Fits each project with care |

| Quality Check | Each harness tested in full |

| Global Reach | Ships worldwide with safety |

| Product Range | From car to health tools |

| Support | Fast help and clear talk |

| Long Life Parts | Built to last many years |

| Skilled Team | Years of deep know-how |

QL-Custom Technology: for Better Products

QL-Custom Technology Ltd. is a top china custom wire harness maker. They give:

- Complete custom wire harness assembly services

- Skilled design and build teams

- Strict tests on each unit

- Safe shipping worldwide

- Wide range: custom OBDII, overmolded cables, Omron switch cable relief, and flat ribbon cable

They value trust with every client. Every order is checked and safe. QL-Custom Technology Ltd. is a smart pick for anyone looking for a steady custom wire harness supplier. They are known for strong service and clear support.

Custom wire harness assembly is all about safety, trust, and extended use. Strong wiring keeps systems safe and sound in cars, planes, health, and defense. The harness works even better with parts like custom OBDII, overmolded cables, Omron switch cable relief, and flat ribbon cables. For best results, work with skilled custom harness manufacturers. QL-Custom Technology Ltd. is a trusted choice for strong custom harness wire that lasts many years.

FAQs

Why use custom harnesses in these jobs?

Because only custom harnesses can meet strict needs. They are built to fit exactly right and work in perfect order. This keeps machines running smoothly and safely. It also makes the equipment last longer and protects the people who use it.

Are they tested carefully?

Yes. Each harness is checked under heat, cold, bending, pulling, and more. Only the harnesses that pass all tests are used. This gives trust that they will work in the hardest places.

Do they resist shocks and impacts?

Yes. They are made to keep working during shakes, crashes, or sudden hits. They hold tight and do not fall apart.

Can they work in space?

Yes. They are made to survive without air, extreme heat, freezing cold, and strong rays. They stay strong even in space.

Are they safe for medical tools?

Yes. They give steady power and data without stopping. Medical tools trust them, because lives depend on them. They are made with extra care to be safe.

People Also Ask

Can a harness take a strong shock?

Yes, they can. These wires are built with tough wrap and strong joints. They stand up to hard shakes, hits, and even drops. In planes, tanks, or space tools, shocks happen a lot. The harness does not break or lose flow. It keeps things safe even when stress is high.

Are they tested more strictly?

Yes, they go through very tough tests. They are put in labs, with heat, cold, fire, and shaking. They are also tested in real use, like air or field tests. Only if they pass all tests are they used. These strict rules make sure no failure happens at work.

Do they cost more?

Yes, they cost more than usual. They use top wires, top wrap, and strong clips. They are built by experts, not by quick work. They cost more, but they save lives, tools, and time. The price is high, but the value is much higher.

Can a harness stand cold?

Yes, they can. These harnesses are made to stay safe in snow, ice, and freezing temperatures. The wires do not crack. The covers do not break. They keep the power flow steady even in cold air or space. This makes them safe for the North Pole, planes, or rockets.

Is small size a must?

Yes, small size is very key. Planes, space tools, and army gear do not have much space. Small and light harnesses save weight and space. This makes tools move faster and use less fuel. Small wires that still stay strong are a big win.

Can wires bend and not break?

Yes, they can bend a lot. They use soft but firm wire that bends easily. Even if you move them many times, they do not crack. They can move with parts of the tool and still keep the flow safe.

Do they meet global rules?

Yes, they meet world codes and laws. They are checked by world labs. They are safe to ship and use in many lands. This makes them trusted for global work.

Can it work in airplanes?

Yes, they can. Planes use them in wings, jets, and gear. They fit tightly in small areas. They hold safe flow even when the plane shakes or heats up. They keep air travel safe.

How do they keep safe?

They use wraps that do not burn. They use seals that stop water and dust. They block sparks and leaks. This keeps tools safe from harm and people from shock or fire.

Is the test done in labs?

Yes, labs push them to the limit. They test heat, freeze, bend, fire, and more. They even test with firm pressure. Only wires that pass all checks are sent out.

Custom Wire Harness with Diagram