Product Introduction

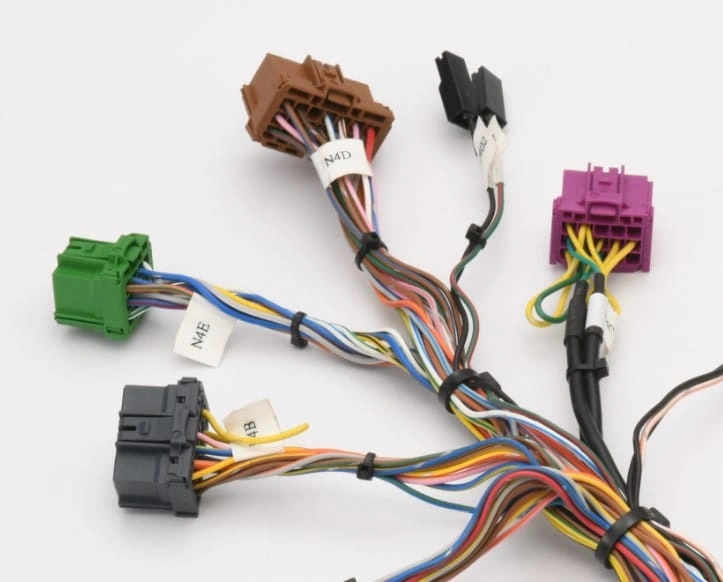

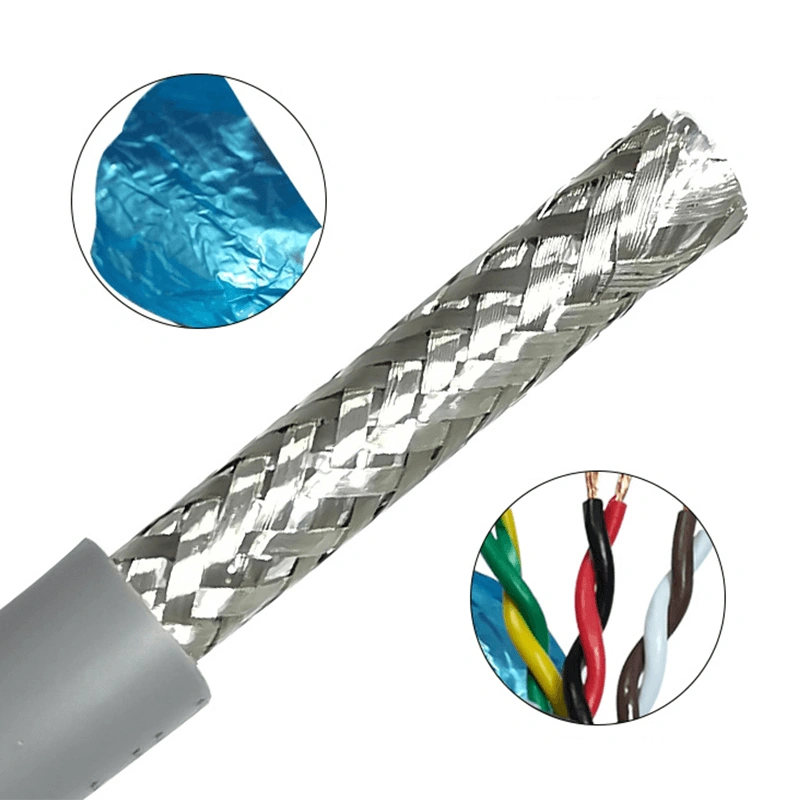

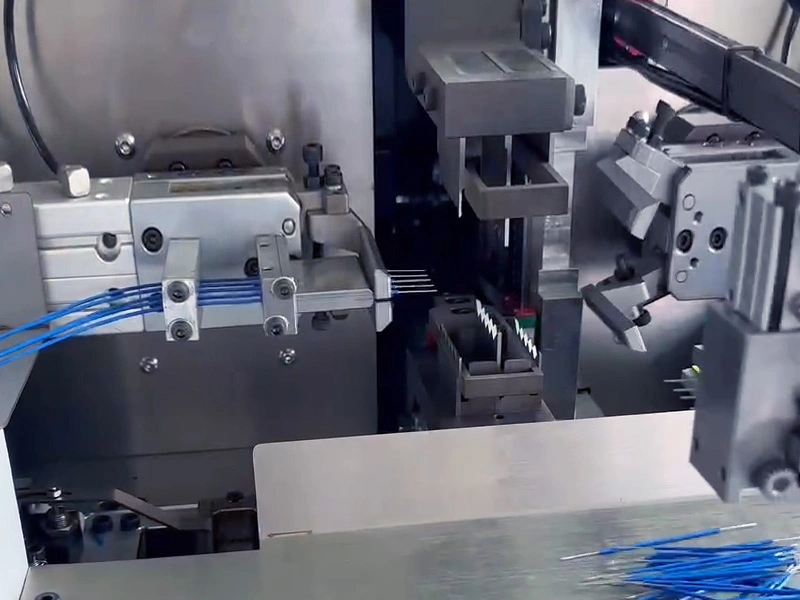

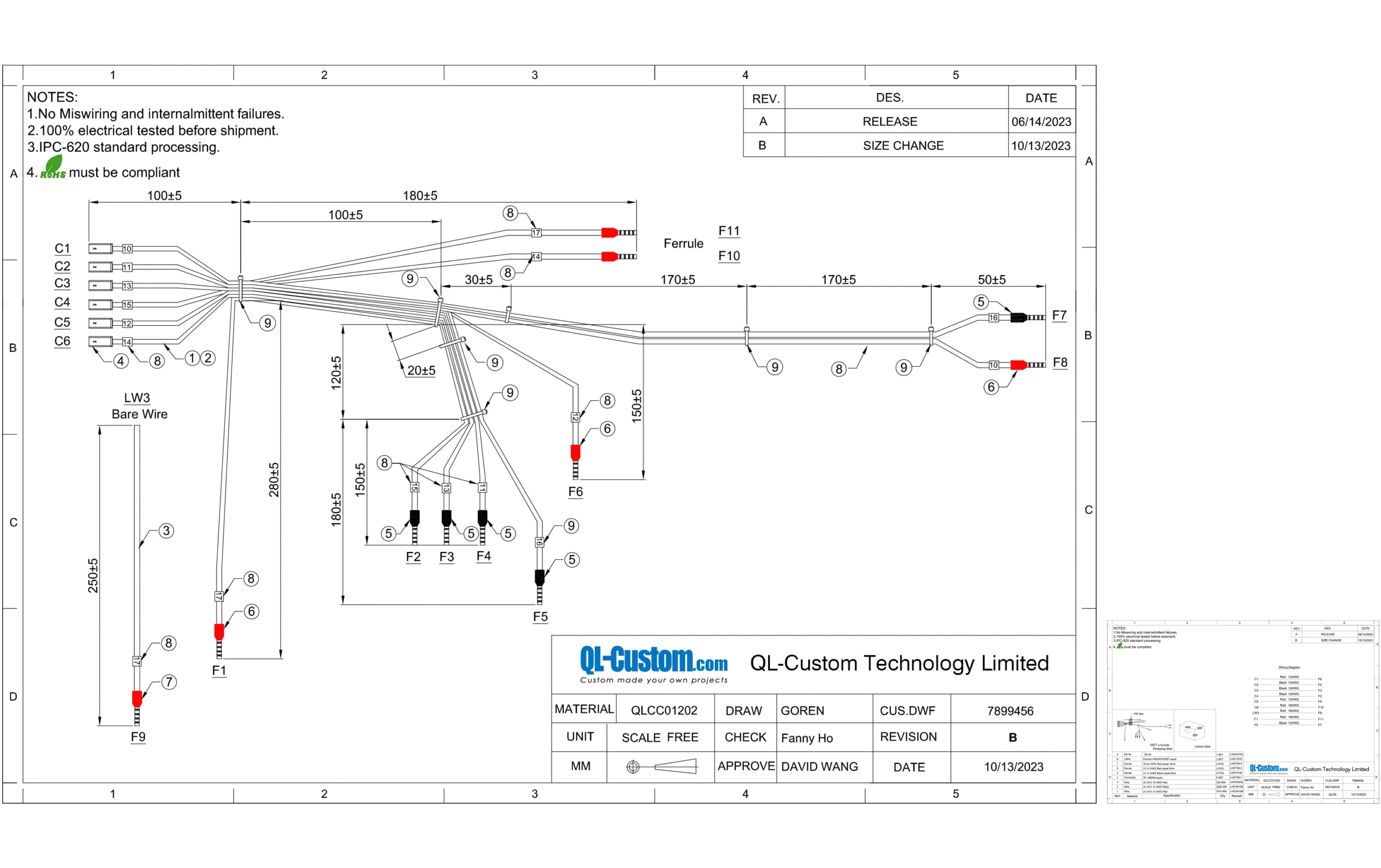

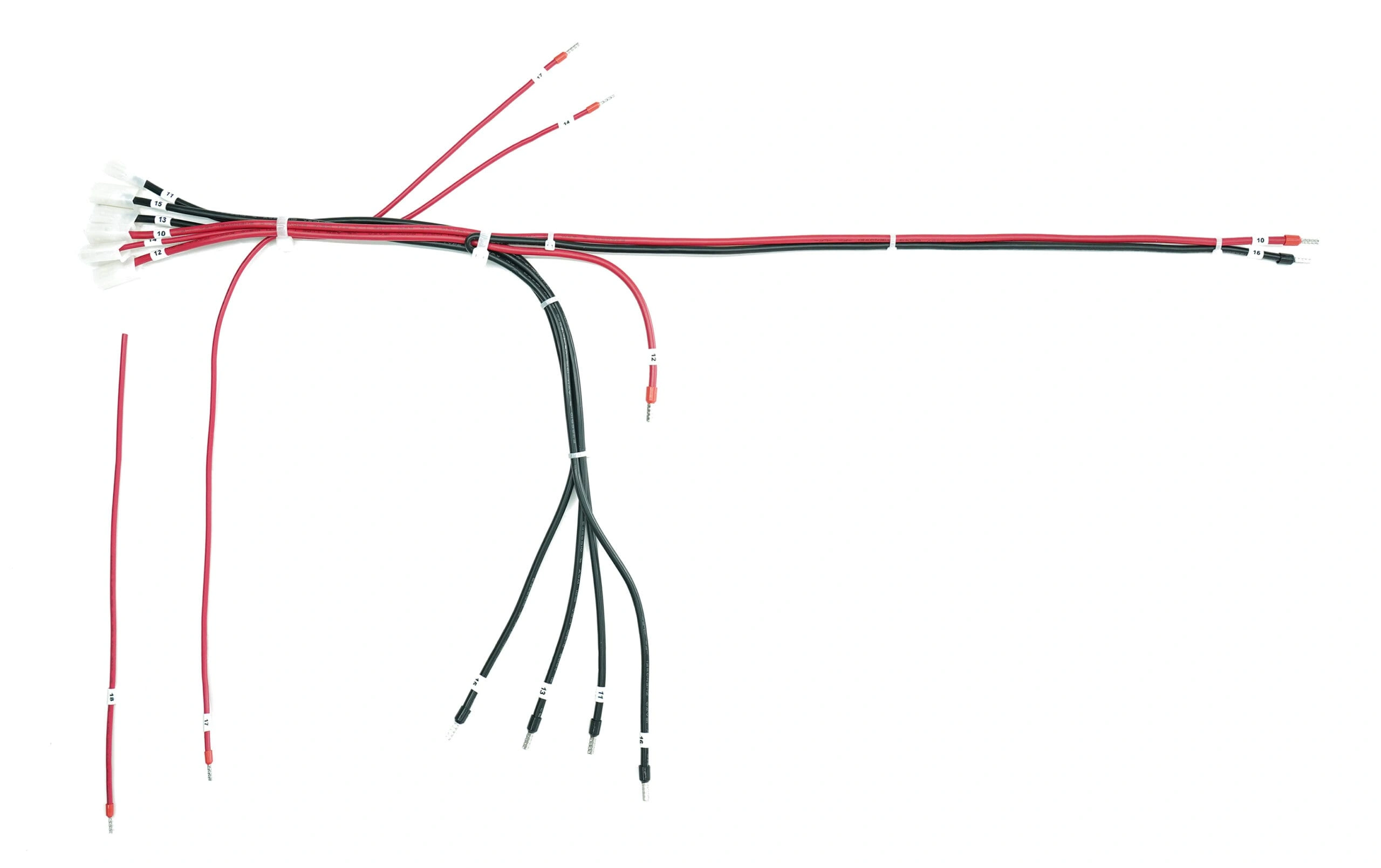

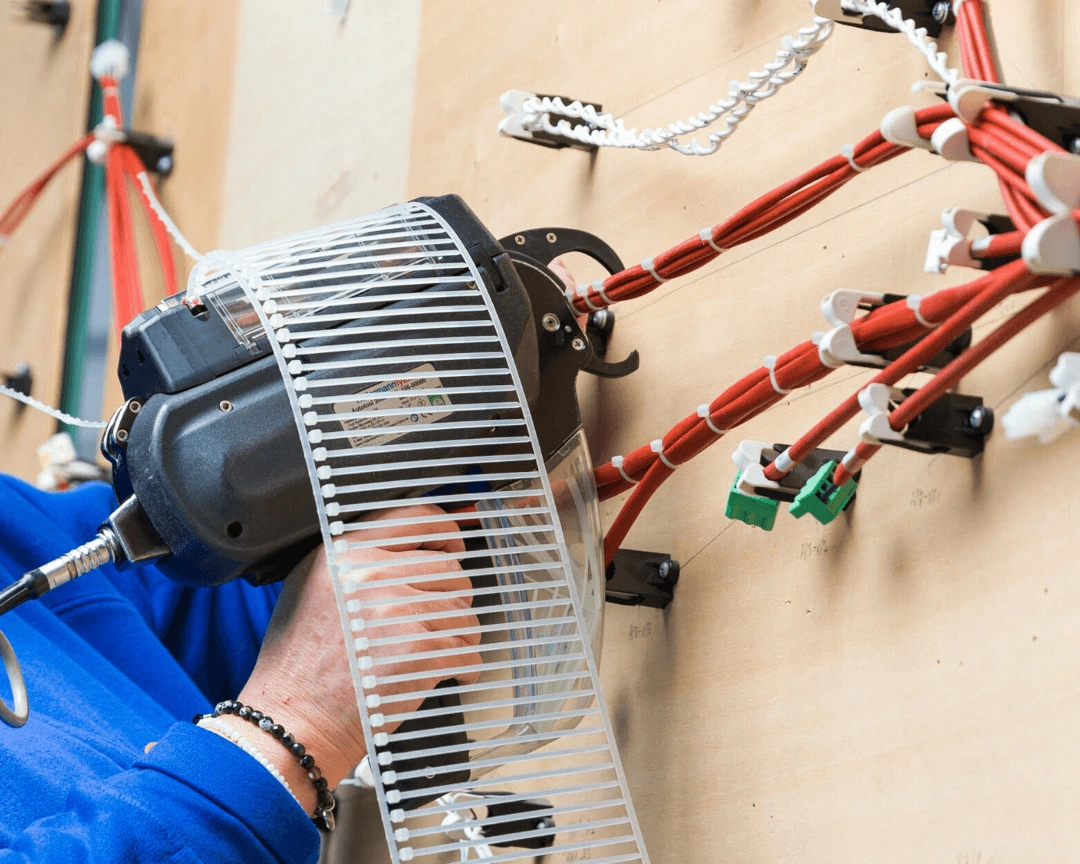

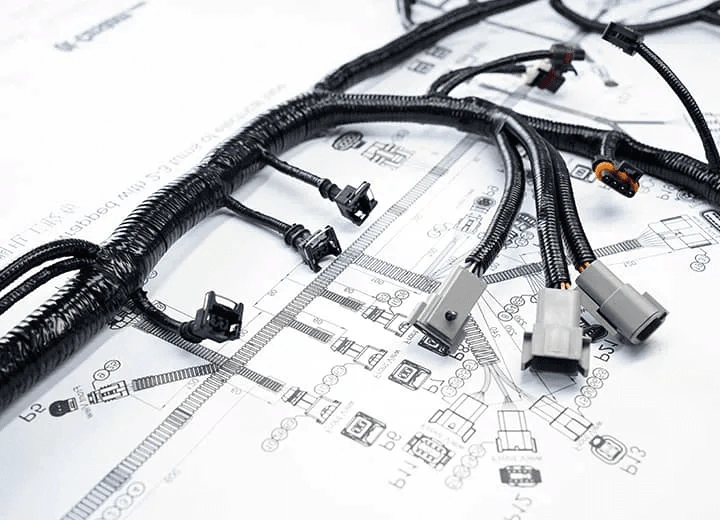

A wire harness is a group of wires and plugs for one job or task. A custom wiring harness ties wires together in one neat, strong set built only for your project. This makes work faster, safer, and easier. A custom harness always keeps the wires together and you easily identify the wires. It keeps the wires and system safe from the harsh weather. This keeps them safe for years. A harness also makes repair simple, since wires are grouped, marked, and easily seen. It keeps the setup clean, neat, and professional. Cars, planes, boats, machines, and even small tools use harnesses. Wireless would get tangled, worn out, and break fast without them. Custom harnesses are essential; they keep power and signals moving safely, securely, and smoothly every day.