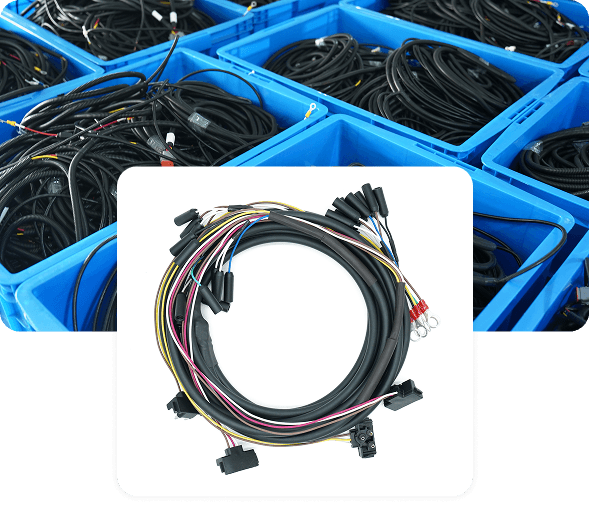

Produkt-Einführung

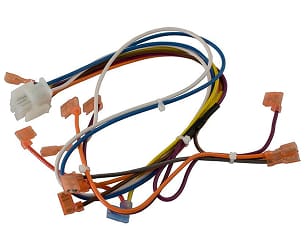

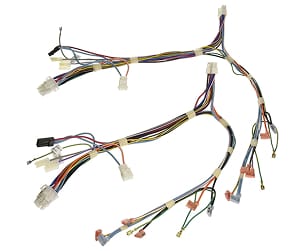

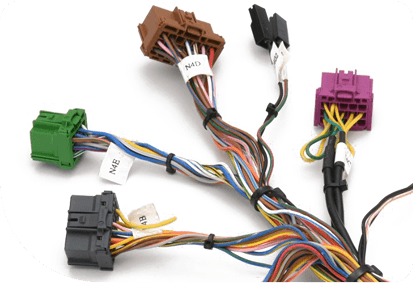

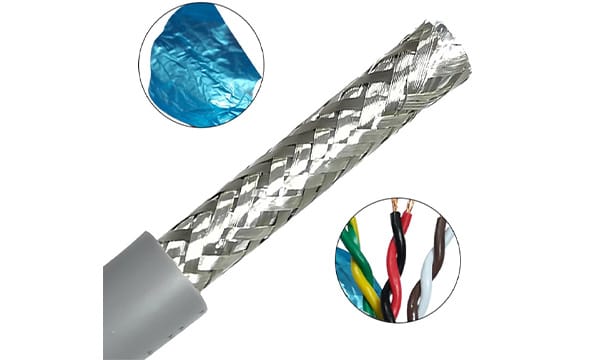

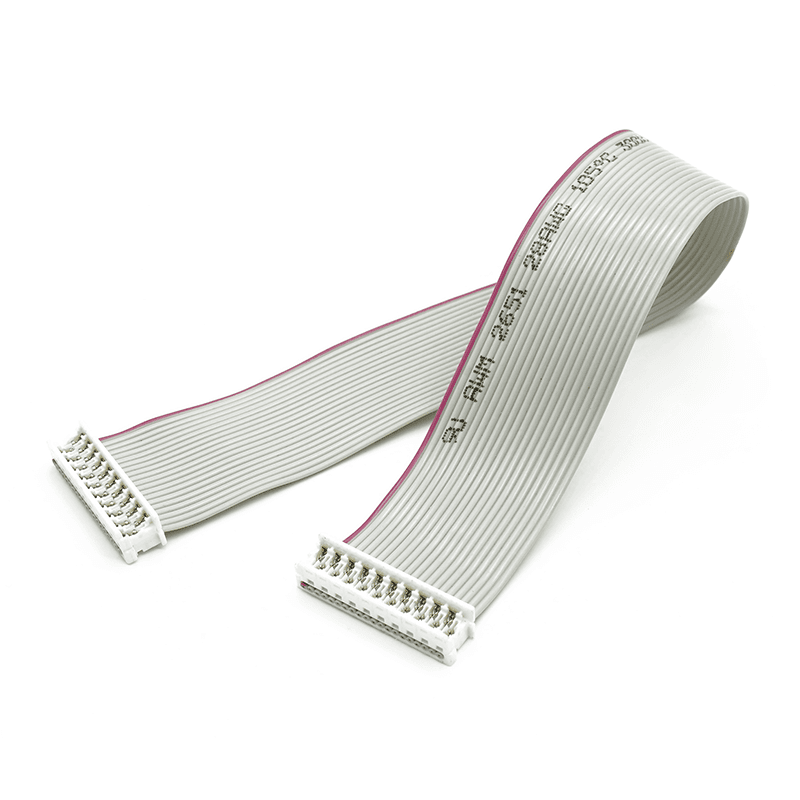

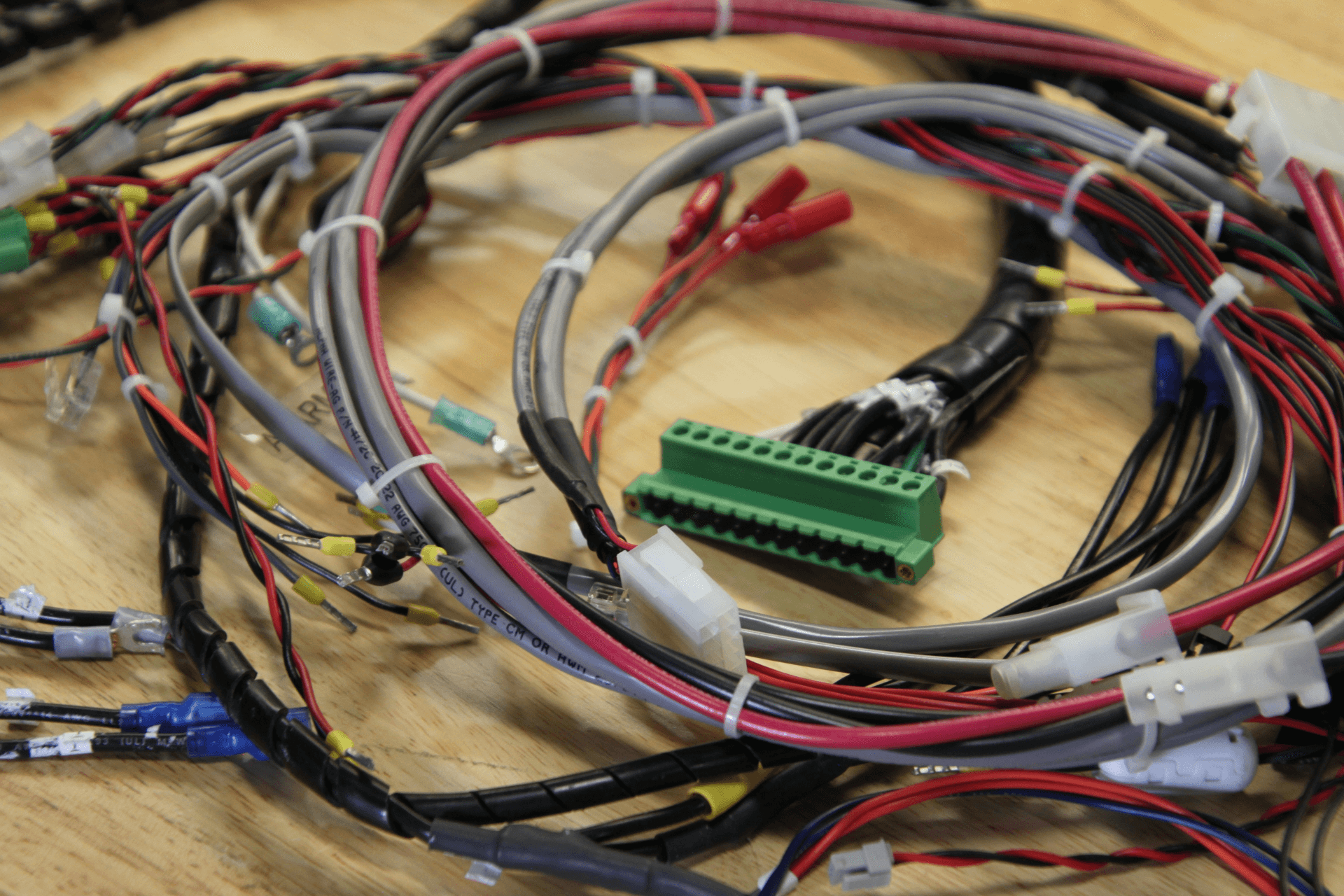

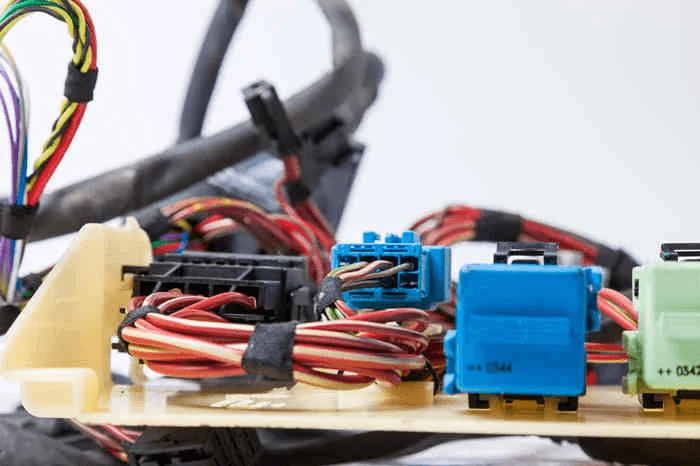

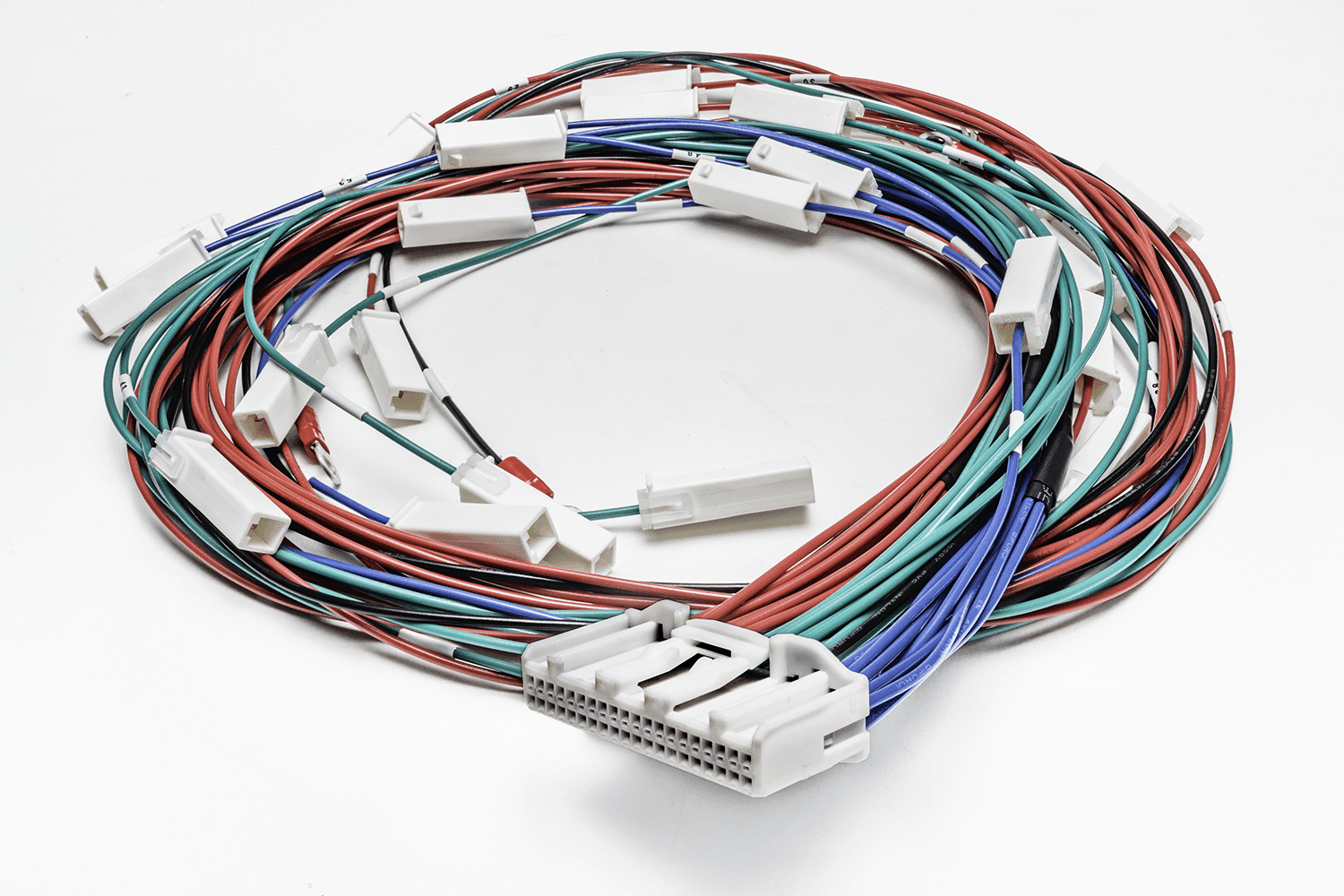

We use premium quality materials to make your custom wiring harnesses. Our team accurately follows your details to make your harness accurately. We have advanced technologies and machines to test and correct the harness design. Each wire is checked and carefully attached to the harness. We especially make the harness to carry both high and low power and signals. With the proper care and techniques, we offer you the custom wiring harness that matches your standards easily.