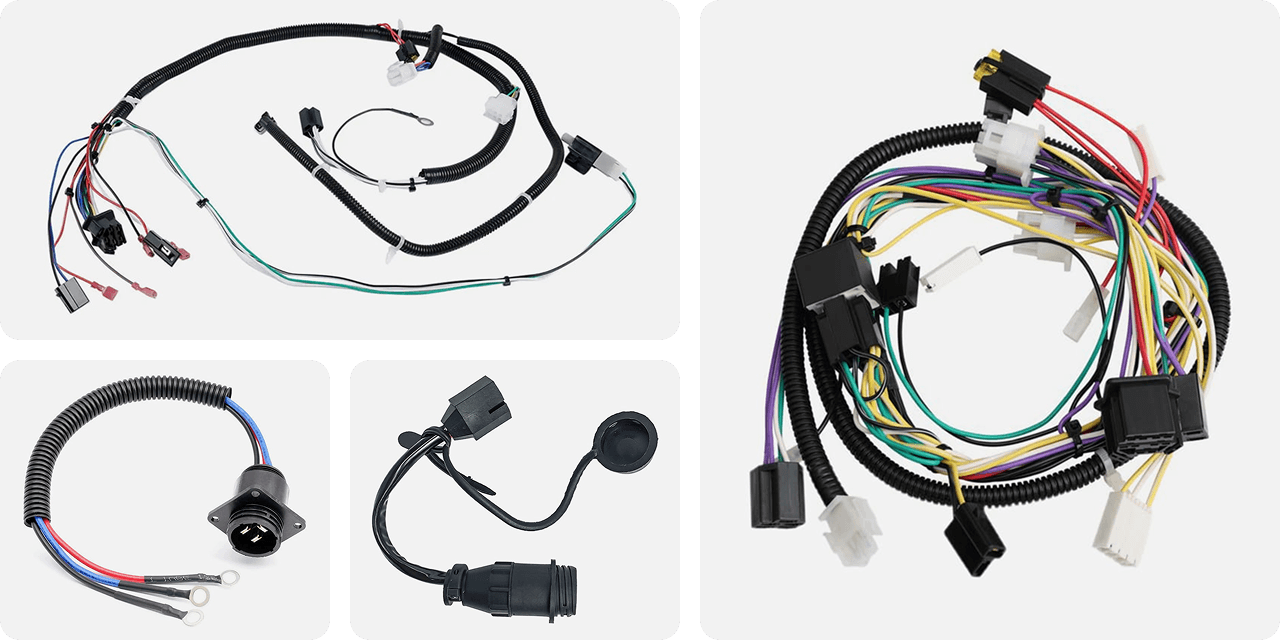

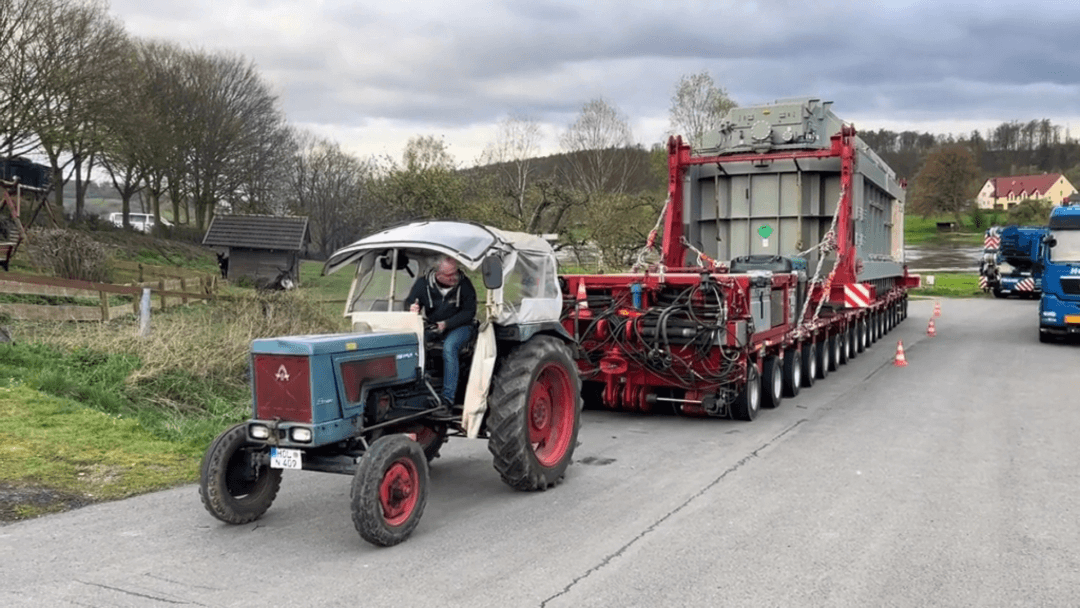

Agriculture and Horticulture

For the farm machines and the tractors these wire harnesses are essential. In the rough areas and tough

weather these harnesses supply accurate power and signals to the tractors body parts. A good harness keeps all

the wires neat and covered so they don’t break or get wet. It connects the engine, lights, and other small

parts that need power or signals. Because the wires stay safe, there are fewer breaks and fewer times the

machine stops. These harnesses help to save time by providing proper services. For the less repairing and

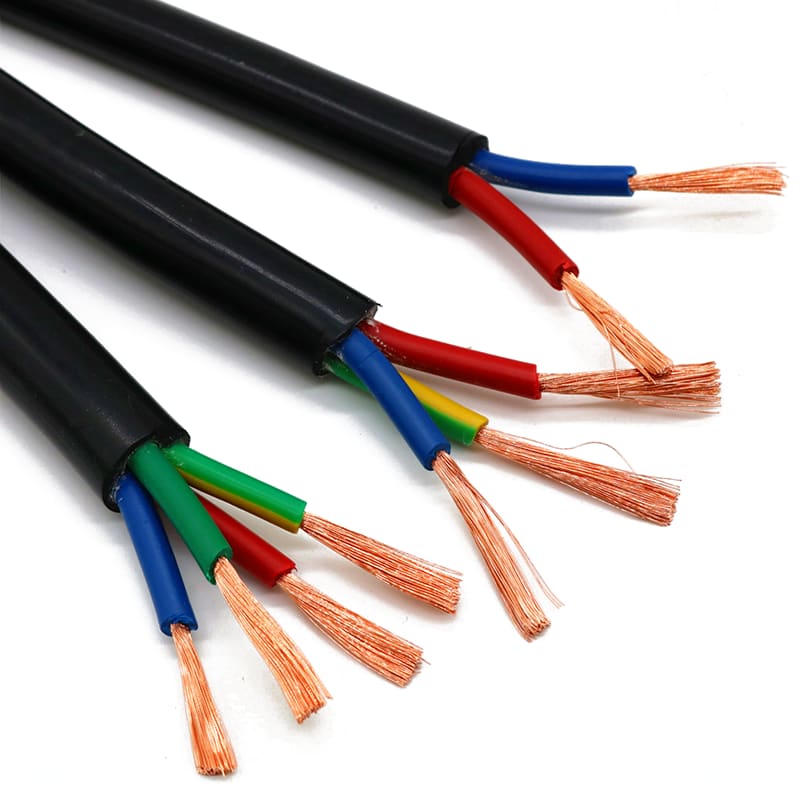

error free performances the tractor wire harnesses are the best choice for the rough conditions. The cables

are made carefully with high quality materials which makes it thick. These harnesses help the farm run

smoothly by providing the best service to the machines.

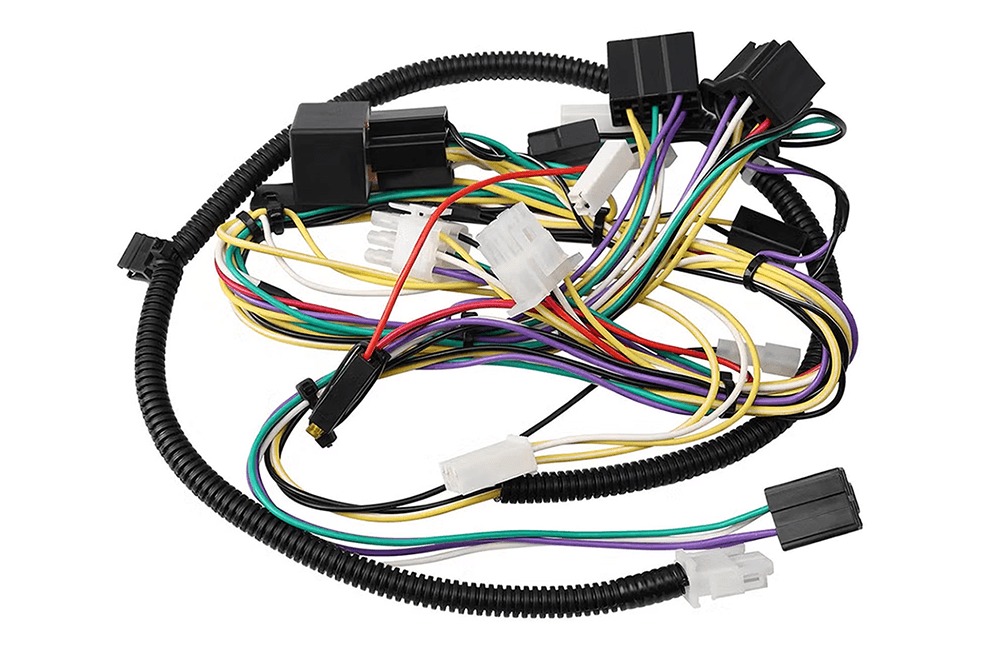

Infrastructure and Construction Industry

To keep the working process clean and safe many machines in these sectors use tractor wire harnesses. These

harnesses keep the wires together and secure for smooth usability. They send power and signals to the lights,

controls, and sensors. Construction places are full of dirt, dust, and shaking, so the harness must be very

strong. The wires are placed carefully so they don’t rub or melt. The thick wrap keeps them safe from rocks,

sharp parts, and heat. A strong harness means fewer stops, faster work, and fewer repairs. Each harness is

made to fit the machine perfectly, so it runs smoothly and safely. This helps workers finish vital jobs like

buildings, bridges, and roads faster and better. When machines work right, work is safer, cleaner, and easier

for everyone on the job site.

Forestry and Timber Harvesting

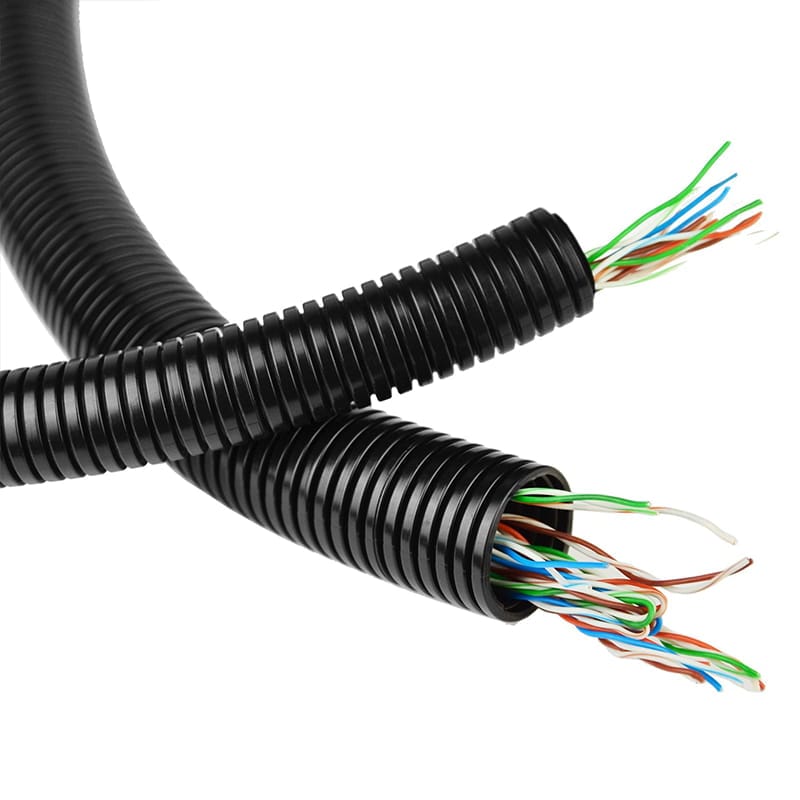

Machines that cut and move wood need super-strong wire harnesses because they work in hard places. These

machines go through mud, rain, snow, and hot sun every day. The harness keeps wires safe from shaking, water,

and heat. It stops breaks and keeps power flowing even when far from repair shops. If a wire breaks, the whole

job can stop, so the harness makes sure that doesn’t happen. It helps saws, engines, and controls keep working

all day long. The cables are tested to survive mud, ice, dust, and tree branches. Strong harnesses make forest

work safer and faster. They let workers move more logs with less waiting or fixing. A good harness means more

work gets done with less worry and less cost.

Municipal and Public Utilities

City trucks like garbage trucks, snowplows, and street sweepers also use wire harnesses. These trucks work in

rain, snow, and on bumpy roads every day. The harness gives power to the lights, sirens, and tools inside. The

wires are sealed tight so water and salt can’t get in. If something breaks, the harness makes it easy to find

and fix. A strong harness helps city workers finish their jobs without long stops or danger. It keeps the

brakes, lights, and engines safe and working well. These harnesses last a long time and follow city safety

rules. They help keep streets clean, safe, and ready for everyone. When trucks and machines work well, the

whole city runs better and faster.

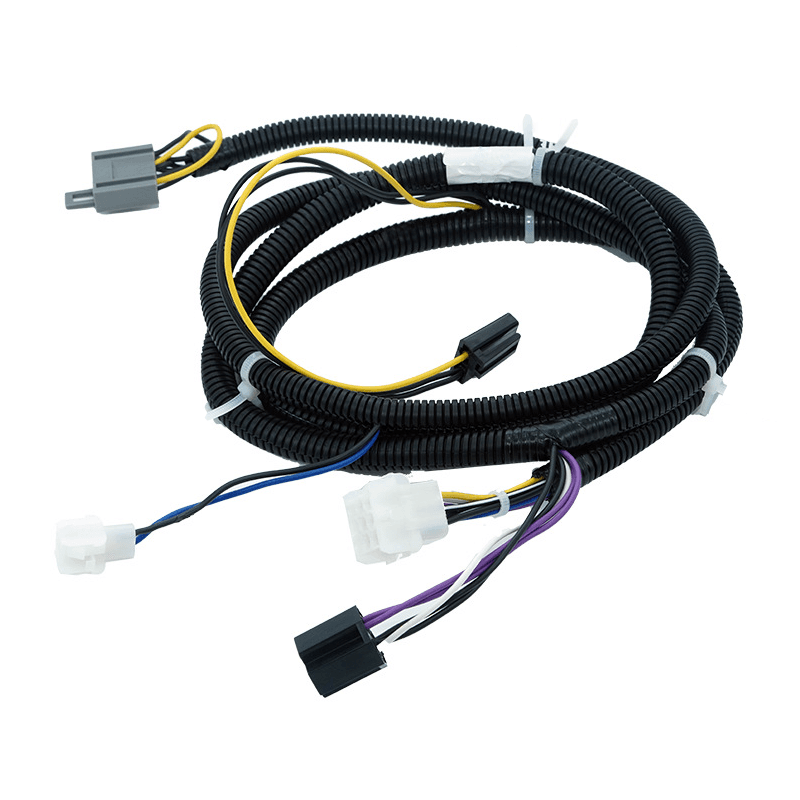

Traction and Logistics Transportation

Trucks, buses, and trains use heavy wire harnesses that last for many years. These harnesses power engines,

lights, and safety systems. They must handle heat, shaking, and long trips. The same kind of harness is used

in trains and machines in warehouses, like forklifts and cranes. When harnesses are made strong, travel is

safer and faster. They stop problems that could cause delays or crashes. Each harness fits its machine

perfectly and bends without breaking. These wires keep people and goods moving safely across cities and

countries. A good harness saves fuel, time, and repair costs. It keeps work smooth and helps companies deliver

on time.

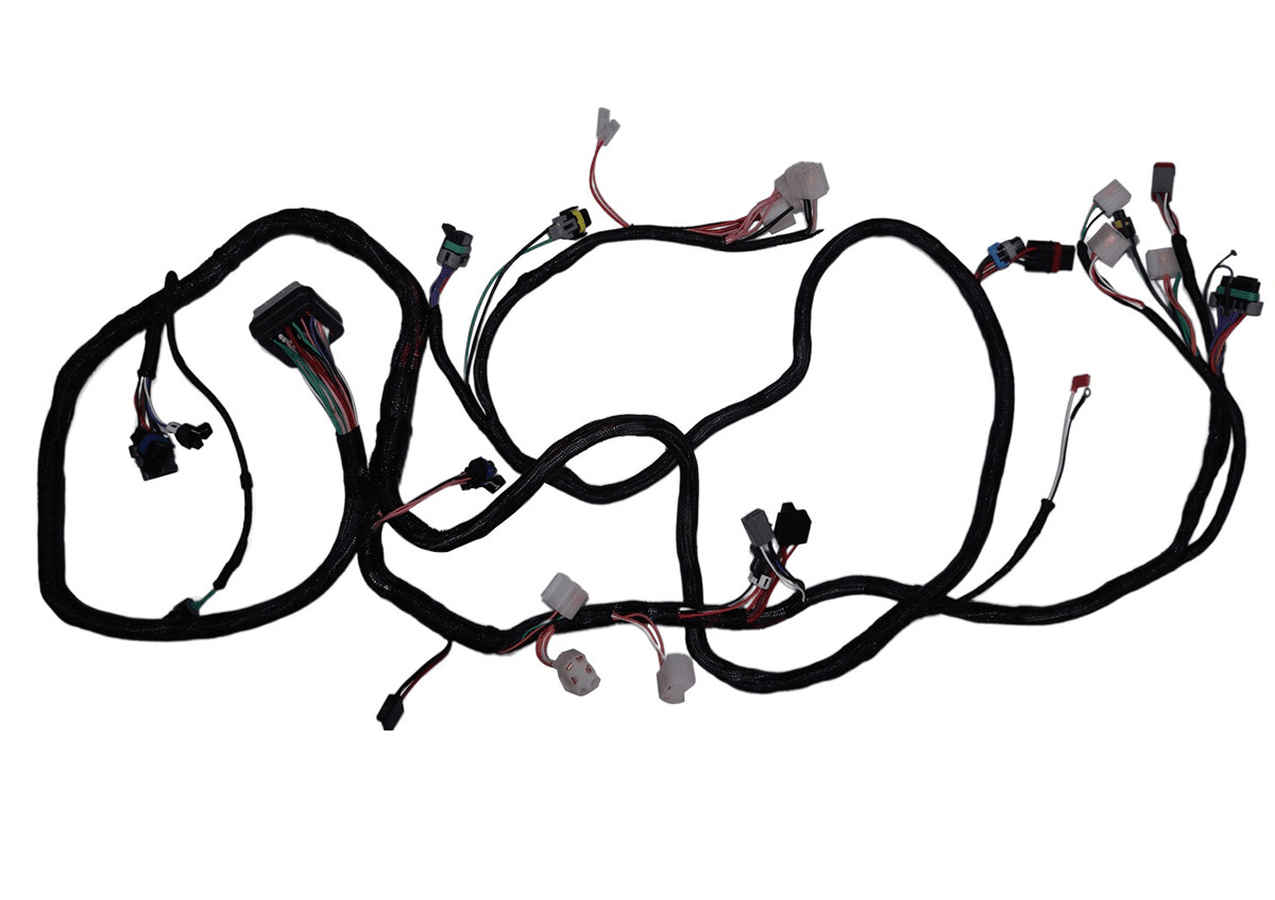

Military and Special Vehicles

Military trucks, tanks, and rescue vehicles use the toughest wire harnesses. They must work in cold, heat,

dust, and rough ground. Each wire is wrapped tight to stop noise and protect from damage. The harness is made

to handle pressure, water, and heat. In a battle or rescue, even one broken wire can be dangerous. That’s why

these harnesses are tested many times before they’re used. They power radios, lights, and tools that must work

all the time. Fire trucks, ambulances, and rescue cars also use these harnesses. They make sure sirens,

lights, and safety gear always work fast and right. Strong harnesses keep people safe and ready to help others

anywhere, anytime.