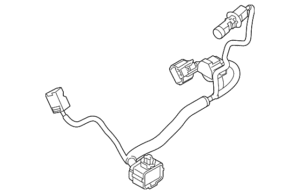

High-Flex Custom Wire Harness for Moving Equipment

By hdhhd shhsbbs / 2025年12月8日

A high-flex custom wire harness has strong wires that can be bent, twisted, and moved around many times without breaking. These harnesses are made to protect users at all times when there are moving parts. The makers of the harness use soft but strong wire, colorful wraps, and well-organized designs to keep it from breaking. Many groups choose these systems because it’s important to protect data, communications, and power in equipment that is always running. Use a high-flex harness to work steadily for a long time, with only a few breaks.

Moving Tools Need High-Flex Harness Parts

Tools that move around a lot need wires that can bend all the time. A frayed wire could break and quickly cut the line, which would hurt the machine. A good harness makes everything work well. This helps motors, arms, belts, and joints get the right data or power flow. Less heat, tension, and pulling forces are other benefits. A lot of brands use custom wire harnesses, custom cable and wire harnesses, and full custom wire harness assembly solutions for this reason. When properly planned, each harness lasts longer and is safer to use.

Built by Trusted Experts

You want a skilled team that knows how to plan and build a strong, flexible harness. Knowing the product’s anticipated bend force, motion patterns, stable use, and daily stress is crucial for a custom wire harness manufacturer. They use clean methods and strict testing on every part. A lot of groups work with a Chinese custom wire harness supplier because they do good work, get things done quickly, and charge fair prices. Brands are also looking for teams that can help with custom wire harness manufacturing, custom wire harness assembly, and careful custom wire harness planning.

Uses in Many Moving Systems

These high-flex sets can be used in a lot of different ways. They are used in robots, elevators, doors, medical equipment, and assembly lines. They are also used in cars, from the dashboard to the trunk. Many businesses now choose custom automotive wire harness, custom car wire harness, and custom engine wire harness sets because they want safe bends, gentle twists, and long-lasting use. These harness parts keep each system strong, even when it moves quickly.

Importances of Custom Made Wire Harness

Each machine moves in its own way. Some move too much. The others move smoothly. Some of them fold or twist. Because of this, there isn’t a single model of harness that works for everyone. For this reason, more and more high-level executives are using custom wire harness design services to make the perfect shape. A company in China that makes custom wire harnesses can make the right length, bend point, jacket type, and cover for you. That way, you can be sure that every part has the right kind of shielding and strain relief.

Recommended Cable Items

Each thing down here has its own job to do. They are all made to last for a long time. In some way, all of them will help your project.

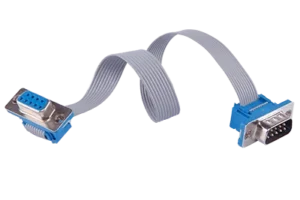

Flat Ribbon Cable

The flat ribbon cable , narrow, and flexible ribbon cable is great for getting around tight spaces. It spreads the wires out evenly, which makes the bend smooth. This type of cable is easy to use with small robots, moving arms, and tight spaces. Because of this, the trail is straighter and less twisted. It is used in a lot of different test tools, advanced toys, and scientific tools.

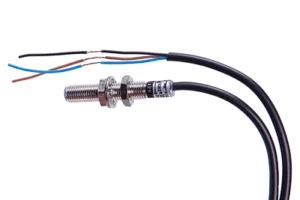

Sensor Cable

The sensor cable’s weak signals need to be kept safe in a clean environment. These signals must not mix with heat or noise. The cable won’t break even if you bend it a lot. With the help of high-quality sensor wires, machines can keep an eye on things like speed, light, weight, and more with great accuracy. They also protect the signal when the tool moves or shakes.

Molded SR

Molded SR gives the stress point extra strength by supporting it close to both ends. This stops the inner wires from getting damaged when the cable bends too much. Because of this, the jacket won’t come apart or tear. Many high-flex setups use molded SR because it makes the cable last longer. It also makes it less likely that a wire will break near the tail.

Overmolded Cables

A thick, flexible sheath covers the place where the overmolded cable wires meet. The casing protects the connection from dust, water, and sharp bends. It also makes it easier to handle, move, and lock the cable. Overmolded sets are great for use in tough or crowded places because they last a long time.

Why Pick QL-Custom Technology Ltd.

Quality, originality, and cleanliness are what QL-Custom Technology Ltd. does best. They fully support custom wire harness assembly, custom-made wire harnesses, and full high-flex setups. They help with design and construction, and they also wrap, test, and pack. They are reliable in all areas of expertise, their prices are fair, and they get things done quickly. You can find more information on their website.

FAQs

How long does a high-flex harness last?

A high-flex harness can last a long time if it is properly cared for and maintained. The length of time a tool lasts depends on how easy it is to move, how many bends it has, and how clean its work area is. With the right wrapping, gentle strands, regular maintenance, and regular inspections, it could last a long time. It also works great when it is kept dry and checked for small scratches on a regular basis. It stays firm and ready for long-term use with little upkeep.

Is it okay to use regular harnesses with moving gear?

You shouldn’t use a regular harness with tools that are always moving, twisting, or changing. Standard wires break easily because they are stiff, thick, and don’t bend. A high-flex type can be twisted, pulled, folded, and swung over and over again without breaking or getting stressed. It keeps the machine safe and helps keep it from breaking down or stopping suddenly while it’s working.

Are high-flex harnesses safe on rough ground?

Yes, a lot of high-flex harnesses stay safe even on rough ground. Their strong covers protect them from vibration, heat, dust, oil, and dirt. These covers keep the wires from getting tangled up in trash and protect them from rough surfaces. This keeps the harness safe in any setting, whether it’s a store, a factory, a busy floor, or outside. With its help, the whole line stays more stable and neat.

Do I get to choose the size and shape?

You can choose from a wide range of sizes, shapes, and architectural styles. You can change the number of wires, the type of wires, how they are wrapped, and how long they are. You can make each set fit your tools, workspace, and job needs. This will make the harness fit better, stay cleaner, and work better.

High-flex harnesses help keep repair costs down?

They do help keep prices down because they are strong, last a long time, and don’t break easily. With a strong harness, you won’t have to stop as often to fix and replace parts. Not only does this make the tool last longer, it also saves time and money. Also, it helps the machine run smoothly and without problems for long periods of time.

People Also Ask

Can robots use high-flex harnesses?

Yes, they work very well for robots. Because they spin, jump, twist, and turn quickly, robots need wires that are stable, flexible, and soft. When robots wear high-flex harnesses, they can move faster, more neatly, and with more stability.

What about the weight?

No, most flex harnesses are small and light. Their thin frame makes it easy and quick to move the instrument. They don’t change the speed or weight of the machine.

Would they need special care?

You don’t need to pay much attention to them. Just keep them clean and dry, and check them for signs of wear and tear every now and then. They don’t need much supervision for long periods of time and do a great job on their own.

Can they stand the heat?

Some of them can handle very high temperatures without getting burned. Using coverings that don’t get hot keeps the wires cool and calm. This helps them stay strong even in hot rooms or on hot work surfaces.

Can they bend over to one side?

You can make a lot of different shapes with these. They can easily bend, twist, spin, sway, and swing because they are so flexible. They are great for tools that need to be moved back and forth a lot.

Would they work for small tools?

In fact, they work with gears of all sizes. They are easy to set up and move around in tight spaces because they are thin and flexible.

Do they save space?

Yes, they are neat and save space. In small spaces, they help keep things clean. They also make it easier for cables to be routed without clutter.

Can they hold a lot of wires, which is what you need?

A single harness can hold a lot of wires. The building is made to your exact specifications, using the right count and wrap.

Can cold weather hurt wires that are very flexible?

Some types stay soft and smooth even when they are cold. To put it another way, they won’t break, get hard, or freeze. They keep doing a great job no matter what the temperature is inside or outside.

Do they help cut down on downtime?

Yes, strong high-flex wires mean fewer stops and breaks. This way, the machine can keep working well without needing to stop or get unexpected repairs.

Custom Wire Harness with Diagram