High Grade Automotive Wire Harnesses for Car Lighting

By hdhhd shhsbbs / 2025年12月8日

On a daily basis, high-quality vehicle lighting can’t do its job without stable and secure Automotive Wire Harnesses. The lights need to be turned on quickly. Their light must not fade. In low light or inclement weather, they must not let you down. Having a reliable automotive wire harness in place makes sure that power moves freely from one component to another. Very carefully, it connects control units, sensors, lights, and switches. J1708 OEM cables offer a higher level of assurance in the clean flow of data and fast signal speed in vehicles of all sizes, from compact automobiles to large trucks. Lights may be turned on instantly with the aid of these cords. They also assist lights maintain their brightness for extended periods of time. Road safety for both drivers and riders is greatly enhanced by this.

Car Lighting Needs High Grade Automotive Wire Harnesses

Every time you start your car, make sure the lights are on. On dark roads, there is no way to turn back. No matter the weather, they keep on working. Lighting could be affected by a frayed cable. Moreover, it has the capability to turn off light bulbs simultaneously. A high-quality Automotive Wire Harnesses keeps the power supply robust and smooth by using the best wire for automobile harness duties. It defends against engine heat. The winter air is less likely to chill you when you wear it. Additionally, it is resistant to shaking caused by lengthy truck routes and harsh roads. It is easy to maneuver and remains steadfast on its course. As a result, light lines are suitable for regular usage in any road condition.

High Grade Automotive Wire Harnesses Products

Designed specifically for truck lighting, these reliable cable types guarantee smooth data transfer and can endure the harsh conditions of heavy traffic.

J1708 6-Pin Male OEM Cable – QLC16072

This J1708 6-Pin Male OEM Cable automotive wire harnesses connection ensures a clean and quick data flow by connecting control devices to lighting systems. Low loss and high trust are achieved by the use of hard pins and smooth signal lines. It doesn’t flex the joint during fast twists and fits snugly in tight places. Clean data and consistent power for truck lights are supported in all road states. Because of this, it is a reliable option for service vehicles, long-distance transporters, and everyday fleet use.

Key Uses:

- Truck Light Control

- Vehicle control unit

- Transfer lines for signals

Truck J1708 Male 6-Pin to Right Angle Overmolded OBDII Female – QLC16019

Particularly in cramped areas like the dashboard and side panels, this QLC16019 model makes good use of available space. Smoothing cable routes in tight spaces and around sharp curves is made easier with the right-angle head. For durability, the overmold incorporates a robust strain guard at both ends.

Major Advantages:

- Effortless layout

- Secure protection against pulling

- Extended durability

Truck J1708 Overmolding 6-Pin to DB9 Female – QLC16018

This QLC16018 automotive wire harnesses connection makes it easy to connect the data lines of trucks to the test equipment and light control units. Fleet maintenance equipment may be easily attached to the DB9 end. The overmold shell prevents any splashing of oil, water, or dust. It also has a bend protector next to the pin zone.

Ideal Uses:

- Tools for testing truck lights

- Ports for data scanning

- Fleet inspection systems

Truck Overmolded J1708 Female to Female Cable – QLC16017

You may quickly build up this QLC16017 model to extend signal pathways. Quick link builds in shop bays are made easier with female ends on both sides. Both sides are bend safe and the form is retained for a long time thanks to the overmold. It shields the pin zone from pulling tension as well.

Preferred Applications:

- Signal augmentation

- Lines of light testing

- Instruments for the fleet shop

Role of Automotive Wire Harness Cloth Tape

Cloth tape has several practical uses beyond securing wires neatly. The cloth tape on an automotive wire harness acts as a grip, muffles noise, and secures the whole group of wires. Inside the door jambs, dash zones, and roof routes, it seals the wires and muffles the sound of shaking. As a result, you won’t hear as much road rumbling and the cabin will be quieter.

On top of that, it protects the entire wire pack with a gentle covering. In the long run, this helps prevent wounds, rub loss, and scorch scars. Cloth tape provides quiet protection and long-lasting usage for automotive lighting that runs inside body panels. Even after years of regular usage, it aids the harness in maintaining its shape.

Importance of Automotive Wire Harness Covers

The primary barrier protecting the various groupings of wires on the vehicle’s chassis and body is the automotive wire harness cover. As a result, the wire skin remains uncontaminated by heat, dust, oil, muck, and water. It also keeps the cords organized and in one secure location. Quick service inspections and repairs are made easier with covers, which saves time and effort.

Near wheels, motors, and beneath flooring, sturdy coverings shield light lines. Hot weather, rock impacts, road salt, and water splash are daily challenges for these areas. A high-quality cover ensures years of trouble-free service and added longevity. In bad weather or on bumpy roads, it helps keep the harness in its complete form as well.

Strength of Automotive Wire Harness Plugs

Tight and clean linkages at both ends are essential for good power flow. Automotive wire harness connectors securely fasten the wire to every component of the system. Flickering lights might be caused by a loose plug. It may also lead to the accumulation of heat within the joint. The pin and connection might be burned and eventually broken by this.

Premium plugs are secured in place by sturdy pins and snug lock tabs. No matter the weather rain, dust, heat, or road salt they remain in clean touch and do not rust. This is extremely important for the rear, side, and signal lights of trucks since they are constantly exposed to rough road conditions.

Automotive Wire Harnesses Manufacturing Process

Constructing a strong wire system begins with a series of deliberate and orderly actions. The production of automotive wire harnesses follows a comprehensive strategy from beginning to finish to guarantee the safety and strength of each unit:

- Efficient power transmission using cores made of pure copper

- Layers of heat-resistant clothing for use in hot climates

- Tools that crimp firmly ensure a secure pin lock

Pull, shake, heat, and full-power tests are just a few of the ways each harness is put through its paces to guarantee it will last. Hand and tool inspections are conducted on each joint. Daily road usage and heavy-duty truck operations in all road conditions are accommodated by this care plan, which delivers a long-life product.

Automotive Wire Harness Cost Per Unit Explained

Many buyers inquire about the cost of automotive wire harnesses per unit before placing large orders. The final price depends on several key factors that shape the entire build and test process from start to finish.

- Wire length and full path size

- Wire type and copper core size

- Plug count and pin style

- Overmold needs and cover type

- Data speed and signal support

A simple light harness is often less expensive in many cases. The brilliant truck data harness incurs higher costs due to additional test steps and shielding requirements. The key point is long-term value, not just the initial purchase price.

Harness Assembly Services for Custom Needs

Each car and truck model is built uniquely with its own shape and layout. Automotive wire harness assembly services help match the exact build needs of each model with complete care. You can choose from various options, including wire size, plug shape, tape type, cover type, and bend path.

Custom harness assembly helps cut waste in both material and time. It also speeds up install time at the shop or factory floor. This saves labor hours and lowers the full build cost over large order runs. It also reduces error risk during installation and helps speed up the final vehicle build.

Best Insulation Materials for Safe Light Flow

Automotive wire harness insulation materials determine how much heat, load, and vibration a wire can withstand daily. The right choice keeps power smooth and safe through all road use and weather shifts.

- PVC for low heat and low power zones

- XLPE for high heat and heavy load zones

- Silicone for flex zones with sharp bends

The proper insulation keeps power smooth and transparent at all times. It reduces the risk of fire, melt, and crack over the long term in harsh driving conditions and on rough road paths.

Choose QL-Custom Technology Ltd. for Top Quality

QL-Custom Technology Ltd. manufactures trusted wire and cable components for cars and trucks, serving numerous global clients. The firm offers complete automotive wire harness solutions under one roof. From design and sample build to final mass test, each step follows strict build rules. They offer strong custom support for small and large orders. They follow OEM-grade test plans for every batch. Their product range encompasses data cables, power automotive wire harnesses, sensor lines, and complete lighting wire kits for various vehicle types.

FAQs

Does a good harness make lights brighter?

Yes. A strong harness makes sure that each light gets power in a fair and clean way. There are no dark or weak spots in the light when the electricity is clean. It also stops flickering or low brightness caused by small dips. It keeps a strong beam no matter how fast the car is going, how fast it is accelerating, or how much it shakes on rough ground. This makes driving at night safer and more accurate now.

Is it safe to use low-quality cables?

No. Low-grade automotive wire harnesses can easily melt, split, or break when they are hot or stressed because they are not strong enough. They get too hot even with small loads, which can cause them to fail or not work at all at important times. They can send dirty or harmful electricity, which can hurt the main light units. Driving at night is more dangerous because they can cause sudden shut-offs.

Can a wiring harness stop lights from going out?

Yes. A good harness will keep all the wires safe by keeping them from rubbing against each other or twisting. Because of this, short faults and sparks that cause failures are no longer there. It keeps things like water, mud, dust, and dirt from getting into the wires’ paths. Because of this, the lights turn on faster and with less delay. It keeps the system dry and clean, which means the light is always safe.

Does a strong vehicle light harness last for a long time?

It won’t break down for a long time if it is made with strong materials that can handle a lot of heat, cold, humidity, dust, and rain. No matter how much the car shakes or moves, it stays in place. It won’t crack, fade, or wear out easily. You can use it without worrying that it will break or stop working. It stays put even on bumpy roads, in bad weather, and on long trips. It helps you save money because it lasts longer than cheap sets.

How hard is it to put on the harness?

Most of them are easy to install, even for people who aren’t tech-savvy. The labels on a lot of harnesses are easy to read, and the connectors snap into place quickly. The clips that come with many sets help you keep your cables neat and tidy. A trained professional can install it quickly, but even beginners can follow the easy steps. It makes the setup peaceful and safe all the time.

People Also Ask

Do fog lights work with high-quality harnesses?

Yes. A good harness will keep your fog lamps steady, bright, and clear no matter what the weather is like, whether it’s fog, rain, or dust. The beam stays clear because it doesn’t lose power. It makes it easier for you to see on roads with low views. It protects the fog lights when the power goes out or gets very dim.

Does it work with older cars?

Most of them will. You can buy new harness sets that will fit a wide range of cars, both old and new. They use connectors that are simple to use and work with most car systems. This makes sure that older cars can get clean, safe light. It can easily upgrade old lighting systems.

Would the heat hurt the wires?

Low-quality wires can melt, break, or shatter when they are too hot. High-quality wires can’t handle much stress or heat. They can handle high temperatures during the day, long car rides, and hot engine compartments. They keep the light system safe from heat damage. They make sure that the lights stay on longer.

Is it bad for the harness to be wet?

A strong harness with tight seals and coverings keeps water away from the wires. It can’t be ruined by anything, not even mud, snow, or the spray from a car wash. It stops dirt, wear, and rust. It keeps the lights safe and clear all year long. Adding it protects the whole line from damage.

Would a harness help when driving at night?

Yes. It keeps the lights bright and clear for long night trips by keeping a steady power supply. It loses its shine after a few hours of use. Lessens eye strain and makes it easier to see while driving. It also helps you stay calm when driving at night.

Can I fix weak tail lights by getting a new harness?

Yes, that is possible. The new harness gives the tail lights full, clean, and even power, even if the old ones were worn out or weak. The end result is a bright, steady, and powerful light show. It also makes the trunk a safer place to be when it’s wet and dark.

Can a harness make off-road rides easier?

Yes. A good harness stays snug and secure even on rough ground. It won’t come apart or move. The lights will stay stable even on bumpy trips because each link is tightly fastened. It makes the car better able to safely drive on rough ground.

Do you know if a harness can stop a fuse from blowing?

A well-organized harness keeps the wires neat, safe, and spaced out, which lowers the chance of a fuse blowing. It keeps the fuse safe from short circuits that happen quickly. Keeps the load steady and smooth.

Is a harness helpful for running lights during the day?

It makes the whole system safer and lasts longer. Yes. For DRL lights to stay bright during the day, they need a steady, smooth flow of electricity all day long. A high-quality harness stops changes and dips, so the flow stays steady. It keeps DRL lights clear, colorful, and easy to see.

Can I use the harness with more lights?

Yes. Many high-end harness sets can handle extra lights without any problems. Their strong cables let them hold more weight. They make sure that all the lights stay bright, steady, and ready, even with more units. It can support more lights without much trouble.

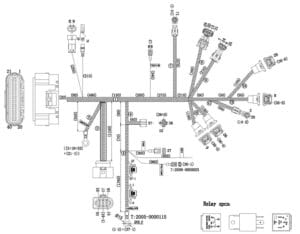

Automotive Wire Harnesses with Diagram