Low pressure molding

By wpname 玩得好 / 2018年5月19日

Low pressure molding

1972 :France IBM first time.

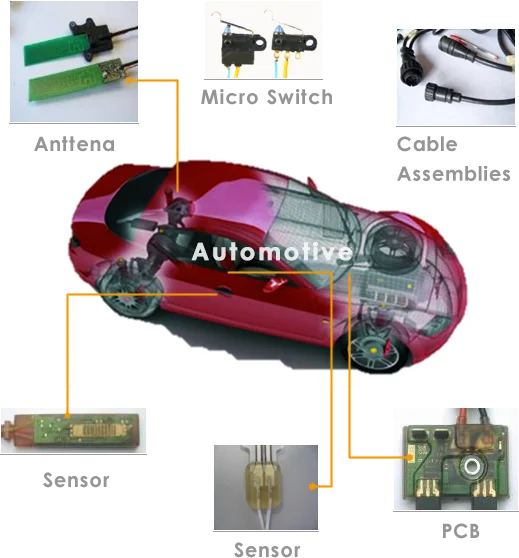

1987 :Eruope automotive start to molding for electronics

1993 :Use for France automotive wiring harness industry

1995 :Wide use for automotive and extended to electronic

2000 :Use for PCB, Sensoring Device and connectors.

After2000: Wide range use for worldwide inudstries.

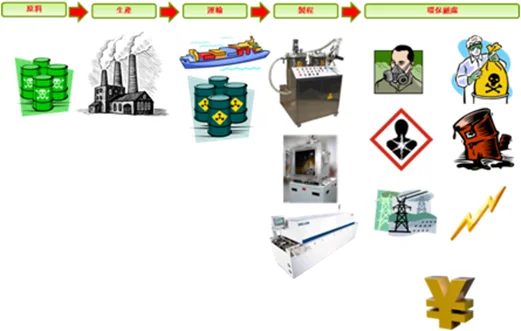

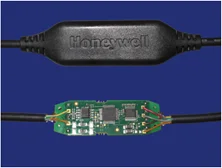

The low pressure injection molding process is a packaging process that uses a very low injection pressure to inject the encapsulating aterial into the mold and quickly solidation. In order to achieve insulation, temperature resistance, impact resistance, reduce moisture, waterproof, dust, chemical resistance.

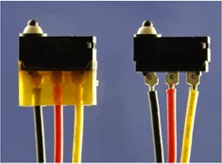

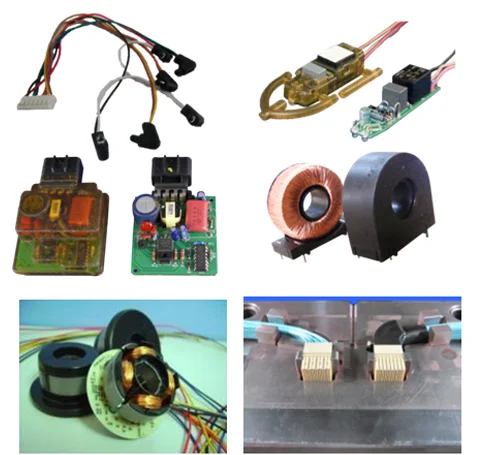

Applies to: circuit boards, electronic connectors, wiring harnesses, batteries, switches, LED lights, coils, etc..

Short injection cycle

Resin Materials environmental protection

The compound does not have to be mixed

Thermoplastics do not require solidation time

High reliability

Simple mold design

Waterproof

Insulation

Impact resistance

Temperature resistance

Chemical resistance

Scrap No harm to the environment

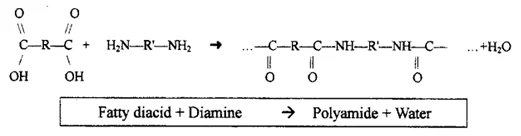

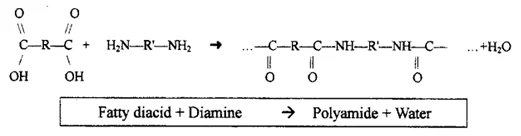

Dimer acid based polyamidoamines are the result of

Dimer acid based polyamidoamines are the result of polycondensation between diamines and dibasic acids.

Dimer acid extracted from common agricultural products

Castor oil

Corn oil

Linseed oil

Peanut oil

Vegetable oil

Tall oil

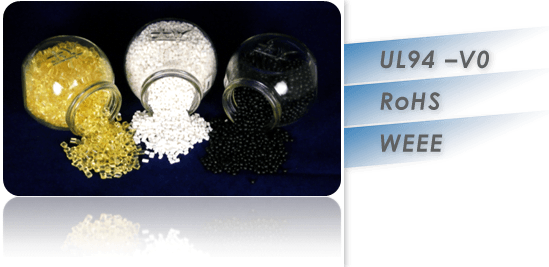

The material is granular Generally black or amberCan be made into other colors

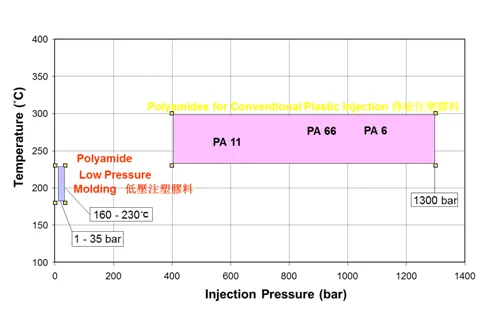

Inejction Pressure1-200psi(0~60kg)

Molding temperature160° C~230° C

Protect the property of IC and components

PA/PO/PET/PUR

QL-Custom sufficient stock

QL-Custom Professional advice

Envirmetal

Good insulation properties, flame retardant properties and corrosion resistance

High Temperature Resistant

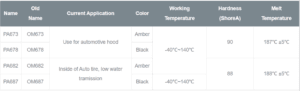

PA673 OM673 Use for automotive hood Amber -40℃~140℃ Shore A 90 187℃ ±5℃

PA678 OM678 Use for automotive hood Amber -40℃~140℃ Shore A 90 187℃ ±5℃

PA682 OM682 Inside of Auto tire, low water tramission Amber Shore A 88 188℃ ±5℃

PA687 OM682 Inside of Auto tire, low water tramission Amber Shore A 88 188℃ ±5℃

Adhesive to Plastics

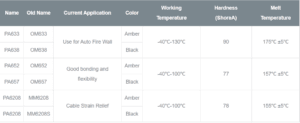

PA633 OM633 Use for Auto Fire Wall Amber -40℃-130℃ Shore A 90 175℃ ±5℃

PA638 OM638 Use for Auto Fire Wall Amber -40℃-130℃ Shore A 90 175℃ ±5℃

PA652 OM652 Good bonding and flexibility Amber -40℃-100℃ Shore A 77 157℃ ±5℃

PA657 OM657 Good bonding and flexibility Amber -40℃-100℃ Shore A 77 157℃ ±5℃

PA6208 MM6208 Cable Strain Relief Amber -40℃-100℃ Shore A 78 155℃ ±5℃

Toughness Resins

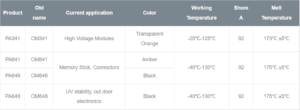

PA341 OM341 High Voltage ModulesTransparent Orange -25℃-125℃ Shore A 92 173℃ ±5℃

PA641 OM641 Memory Stick, Connectors Amber -40℃-130℃ Shore A 92 175℃ ±5℃

PA646 OM646 Memory Stick, Connectors Amber -40℃-130℃ Shore A 92 175℃ ±5℃

PA648 OM648 UV stability, out door electronics Black -40℃-130℃ Shore A 92 175℃ ±5℃

Chemical Resistance

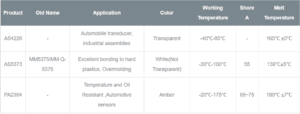

AS4226 -Automobile transducer, industrial assemblies Transparent -40℃-85℃ -165℃ ±5℃

AS5373 MM5375/MM Q-5375 Excellent bonding to hard plastics, OvermoldingWhite(Not Transparent) -30℃-100℃ Shore A 55 139℃±5℃

PA2384- Temperature and Oil Resistant ,Automotive sensors Amber -20℃-175℃ Shore A 65 ~75 189℃ ±7℃

UV Resistant Low Pressure Molding plastics

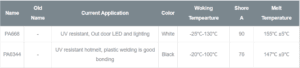

PA668- UV resistant, Out door LED and lighting White -25℃-130℃ Shore A 90 155℃ ±5℃

PA6344- UV resistant hotmelt, plastic welding is good bonding Black -20℃-100℃ Shore A 76 147℃ ±9℃

Encapsulation advantage

Machine price advantage

Mold price advantage

Can injection precision products because:

Low pressure + low temperature

Short product injection cycle

Simple mold design

Because we are dedicated to the development of low pressure injection molding technology

Because we provide a full range of low pressure injection solutions

Because we are advance 7year with international low-pressure injection molding technology

Because we have the best team