Industrial Custom Wire Harness for Automation Sectors

By hdhhd shhsbbs / 2025年11月1日

Modern machines utilize numerous wires to function. These custom wire harnesses carry power and signals that enable each part of a system to communicate with one another. Custom cable and wire harness products make sure everything stays safe, clean, and connected. They are essential in factories, as well as in robots and all automated machines. Let’s learn how these special cables keep industries running smoothly and efficiently. These harnesses are built for the automation sectors where the accuracy and the durability both are essential.

Basics of Custom Wire Harness

A custom electrical wire harness is a bundle of wires tied together. These wires send power or data between different parts of a machine. They are made to fit a machine’s exact shape and needs. A aangepaste kabelboom manufacturer carefully crafts each harness to ensure that no wire is wasted or misplaced. The cables are covered and arranged to stay safe from heat, pulling, and dirt.

Some harnesses utilize special colors, connectors, or coatings to enhance their strength and facilitate easier repair. This helps the system remain stable and run continuously without interruption. In automation, every wire matters because a single loose wire can prevent a machine from functioning properly.

Why Automation Needs Custom Wire Harnesses

Automation machines work non-stop. If wires are messy or weak, they can break, causing production to stop. That’s why a custom wiring harness assembly is used in most factories. These harnesses keep wiring neat, strong, and easy to find. They also save time when repairing or upgrading parts.

Main Benefits:

- Neat and easy-to-check wiring

- Quick to install and fix

- Built with strong, heat-safe parts

- Made to fit each unique machine

A well-designed wire enables machines to run longer with fewer problems. For busy factories, this means more work is done and less time is wasted.

Custom Wire Harnesses Automation Sectors

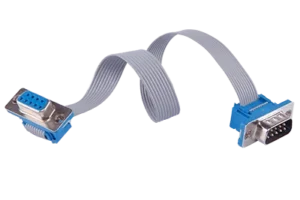

Flat Ribbon cable for Flexible Automation

Flat Ribbon Cables are thin and soft. They can bend and fit easily into small spaces. These cables are used in robots, computers, and control systems that need fast movement and easy wiring. They are very light but still strong.

Why Pick Flat Ribbon Cable:

- Small and flat, saves space

- Simple to connect or replace

- Fast and smooth signal flow

- Bends easily without breaking

If your system needs flexible and tidy wiring, QL-Custom Technology Ltd., a top china custom wire harness supplier, has great ribbon cable options that work for all kinds of machines.

Molded SR Cable for Extra Strength

Molded SR (Strain Relief) cables feature a thick, molded end that prevents wires from breaking. They are designed for machines that frequently move or vibrate. The molded area provides extra support, ensuring the wire remains strong and secure.

Main Features:

- Handles bending and pulling

- Works well with moving machines

- Lasts longer than regular cables

- Can be made in different lengths and sizes

QL-Custom Technology Ltd. manufactures durable SR cables through custom wire harness fabrication, designed to withstand stress and prolonged use.

Overmolded cables for Tough Places

Overmolding kabels have a thick plastic cover molded around the ends. This keeps out water, dust, and oil. They are used in outdoor machines, food factories, and areas with heavy work where regular wires might be damaged.

Why They’re Great:

- Safe from water and dirt

- Lasts longer under hard use

- Protects connectors from breaking

- Easy to hold and use

With QL-Custom Technology Ltd., you can obtain custom wire harness designs featuring strong, overmolded cables that withstand prolonged use, even in harsh environments.

Custom OBDII Cable for Automotive Systems

Aangepaste OBDII-kabels help test and read car data. They connect scanners and tools to car systems. This helps find problems and keeps vehicles running smoothly. They are an essential part of any custom automotive wire harness.

OBDII Cable Benefits:

- Reads car data fast

- Connects safely and tightly

- Works with most test tools

- Helps fix cars faster

QL-Custom Technology Ltd. manufactures custom engine wire harnesses and OBD-II cables that comply with safety regulations and are compatible with all types of vehicles.

Industries That Use Custom Wire Harnesses

These cables and harnesses are used in many areas, such as:

- Factory automation

- Robots and control systems

- Cars and electric vehicles

- Medical tools and lab machines

- Airplanes and electronics

- Home and industrial machines

Each of these fields relies on a clean and safe custom wiring harness assembly to function correctly and prevent breakdowns.

Trusted Supplier: QL-Custom Technology Ltd.

QL-Douane Technologie Ltd. is the most reliable and trusted supplier for the Custom Wire Harnesses. They offer the best quality harnesses for the automation industries. They use the high quality materials that are securely tested and connected together. You get the most advanced quality harnesses that are made to last for many years. The services they provide are the most professional and friendly type. Buy from them to get the best harnesses.

Their Services:

| Service | Description |

| Ontwerp | Custom wire harness design for your machines |

| Fabrication | Strong wire harness fabrication using safe materials |

| Testing | Each harness is tested before shipping |

| Support | Full help and after-sale support |

The teams and the technology used are the most advanced and best quality.

Automation depends on strong wiring that lasts. QL-Custom Technology Ltd. provides reliable and long-lasting aangepaste kabelboom fabrication solutions for various industries. From Flat Ribbon Cables to Overmolded and OBDII cables, each one is made to keep power and data flowing smoothly.

FAQs

Why are wire harnesses used in automation?

Custom wire harnesses are the tools that are best for keeping the wires together. To pass the powers and signals through the wires to the engine and control panel these are the best choice. These harnesses help in the automation process. They keep the whole power system running; these are the best choices.

Can I get a wire harness made for my factory machines?

Yes you can produce the design or ask us to help you in making the design for your harness. After that we collect all the information and then we carefully manufacture the harness.The custom made harnesses make it easy to set up the whole process.

What materials are used in industrial wire harnesses?

These harnesses utilize strong materials, including copper wire, rubber, and plastic covers. These layers protect the cables from heat, water, and dirt. Some even use metal shields to block extra electric signals.

How long does it take to make a custom harness?

It depends on the size of the project. For the small projects we handle in a few days and for the large projects we handle it in weeks for accuracy. We try our best to offer the best harnesses in less time. Every harness is carefully tested for exact accuracy..

Can wire harnesses work in harsh places?

Yes these harnesses are made with the materials that are high quality and tested for many times. The wires and the shield are durable enough to resist the rough weather. The harnesses are connected properly and sealed carefully to resist the dirt.

What makes custom harnesses better than standard ones?

Custom harnesses are made for your exact machine. They fit better, work longer, and are easier to install. They also appear cleaner and require fewer repairs than standard ones.

Mensen vragen ook

Are wire harnesses used in robots?

Yes, robots need harnesses for their moving parts. The wires help send signals to the arms and sensors safely.

Can wire harnesses handle high voltage?

Yes, they can. Some harnesses are designed for handling heavy power and strong currents. They can work safely without melting or burning.

Are there waterproof wire harnesses?

Yes, some harnesses are sealed so water and dust can’t get in. These are great for outdoor or wet areas.

How do I choose the correct harness?

Consider your machine’s size, space, and power requirements. The right one should fit well and handle the job safely.

Can old machines use new wire harnesses?

Yes, new harnesses can improve the performance of old machines. They help improve safety and performance.

Do custom harnesses save time?

Yes, they make setup and repair faster. Since the wires are already organized, workers can complete their jobs more quickly.

Are there color codes in wire harnesses?

Yes, each wire has a distinct color, making it easy to identify. This helps during setup and repair to avoid mistakes.

Who makes industrial wire harnesses?

Many companies make them for machines, robots, and cars. Skilled workers design and test each harness for safety.

Can I repair a broken wire harness?

Yes, but only trained people should do it. They know how to safely repair wires without damaging the system.

Do wire harnesses help reduce machine noise?

Yes, they do. When wires are tight and steady, they vibrate less, which makes machines run quieter and smoother.

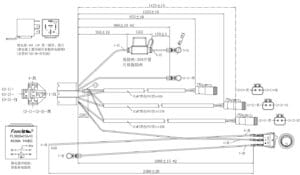

Aangepaste kabelboom met diagram