What is a Cable Assembly

By wpname 玩得好 / 2016年7月5日

What is a Cable Assembly

The standard definition of cable harness assembly or wire harness assembly is a string of wires or cables that are used to transmit signals and information in the form of operating currents. These assembly units are implemented in different industries such as transportation, automotive, electronics, agricultural, appliances, industrial and other industries worldwide.

What is Cable Assembly?

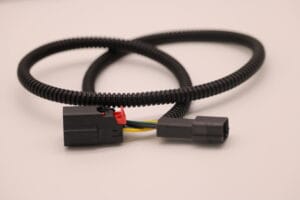

Cable assemblies are a bunch of cables that are used to efficiently transmit signals from one point to another. These are a bespoke collection of a number of wires that are exactly cut to the length and are commonly bound together by conduit, clamps, cable ties, cable lacing, straps, electrical tape, sleeves, and a weave of string or a combination of such similar materials. This allows several wires to be laid along the same path at the same time.

Why Use Cable Assembly?

There are many advantages to using cable assemblies.

This assembly is sometimes also called as cable harness assembly or wire harness. They are much safer to use and give an organized and a robust look as compared to loose, dangling wires found in work or domestic places. They allow for stronger securing of cables too. The neatness of the cable assemblies reduces the loose wiring and all the damage that is likely to be caused. Such assemblies are particularly useful in industries that have machinery because they reduce the chances of loose wires and electrical damages. The binding that connects the cables in the assembly unit also reduces the vibrations caused by the machinery. These bindings can be specified to be flame resistant too, thus, reducing the chances caused to the cables by electrical fire.

These assembly units are not only being used in the technical equipments, they are also being used in different industries and buildings due to the safety they provide. The main use of these assemblies is to reduce the number of loose trailing wires which in turn, leads to fewer accidents in workplaces as well as domestic sectors. Nowadays, they are often found in automobiles where multiple wires have been fitted into a small space. They are also found in server stacks and computer rooms to group together computer peripheries that perform related tasks.

The benefits of using cable harness assembly does not end with optimizing space and helping to keep cables organized. The binding cables considerably offer increased resilience. They are way too secured against the abrasions and vibrations. Also, the combined strength of the multiple bound cables gives them strength affiliated to corded string.

Although modern tools and advanced computer technology helps in designing many customs cable assemblies, the true creation of the cable harness usually continues to be done by hand. This calls for the correct aligning of all the cables or wires and careful assembly for all the components involved in the design. These days, due to the increasing complexities in the businesses and rising market demands, electronic manufacturers generally depend on authentic box build services to cater labor, expertise, skill and resources. Nonetheless, while hiring any box build services or contract engineering company, ensure you check their reputation and credentials in the market.

How the cable collecting is finished?

A cable harness is made by grouping multiple wires in a very series. The harness is then connected to the supply to transmit the knowledge and therefore the signals. The wires square measure exactly cut as per the need of the meant application and square measure certain along by suggests that of various clenches like cable ties, clamps, cable lacing, sleeves, electrical tapes, passage and similar materials.

When you remark manufacturing circuit boards, note that this will be not a simple thing; rather it’s associate extended and complicated technique. the entire technique consumes time, wants knowledgeable brains, technology and electricity, and much plenty of. of those unit accustomed move for manufacturing the tip product, i.e. your mobile, or ADPS or the opposite instrumentation you see around you.

The PCB (Printed Circuit Board) integrates all chips and microprocessors to form the operational a region of every device. So, uncalled-for to say, PCB assembly is that the foremost vital admit the manufacturing of all electronic devices. Here we’ll discuss regarding but electric circuit board assembly is finished. So, let’s begin.

Beforehand, it’s good to understand that we tend to tend to do not appear to be attending to cowl PCB vogue and manufacturing. so what we’ll discuss is what’s done to the PCB once it’s manufactured, means PCB assembly or integration to any or all microprocessors and equipments.

The reason these materials square measure getting used is that they permit the cables to be aligned and positioned on an equivalent path absolutely, and create the complete assemblage sturdy and safe. moreover, facilitate|they assist} the assembly look absolutely organized and help scale back the vibrations generated by the machinery.

If your area of operation involves ordering wiring harness for your various needs here is a checklist for the same Check out whether the manufacturer you are ordering from is UL listed and/or CSA certified. It can be either or both depending on your specific needs. This also applies for extension cord suppliers and manufacturers. See if the manufacturer can offer wiring harness solutions right from simple processed wire to complete wiring harness assembly consisting of many leads and connectors Also check out if they have the capability to provide customized solutions as per the needs of your specific industrial application area. It should also be equipped with state of art machines to offer complete backward integration for manufacturing critical harness as well locking plug components, as and when required. This also include being equipped with the right machines like applicators, jigs, assembly boards and circuit checking boards to enable process design control and flexibility.

Find out from their website or from personal contacts if they have the sufficient experience in various fields like automotive industry, material handling equipment industry, white goods, office automation, medical diagnostic equipment, electrical and electronic equipment. Additionally, make sure that they use the best available terminals in industry that consists of AMP, Panduit, Molex, etc. To avail the quality products, it is always advisable to go online. So, check out if they have online presence in the form of an individual website.

Also go through the customer reviews to get a better idea about the quality of wiring harness and other products produced by the manufacturer. Well, all this is impossible without having the right manpower. A good manufacturer and service provider should be equipped with an extraordinary team of technicians, managers, planners and strategists to meet the all kinds of requirements And yes, also find out if they maintain 100% production & shipping schedule. Only a manufacturer or supplier committed to ultimate customer satisfaction can provide the same whenever and wherever required. A quality manufacturer of power supply cord and locking plug etc would also provide the right kind of customer support team for guiding its customers in selecting the right wiring harness solutions for their individual industry needs. Now, that you know the qualities of a good wiring harness manufacturer, try them and you can never go wring with your choice of service provider or supplier.

On this same note, any manufacturing company should work in a close-knit with their customers to meet their exacting specifications and requirements regarding the types of connectors (male and female), types of wires, retention systems, shielding, handles, and finishes.

Nonetheless, the primary benefits of a cable wire harness assembly does not end with helping to maintain the cables in an organized manner and optimize space, the binding cables substantially offer increased resilience too. They are the last word when it comes to security against vibrations and abrasions.