Wire Harness Manufacturer

By wpname 玩得好 / 2021年8月13日

Wire Harness Manufacturer

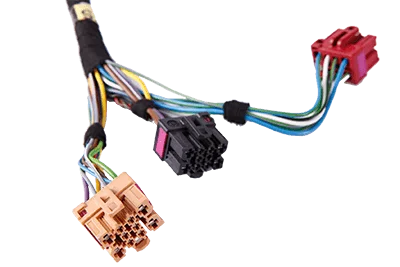

QL-Custom Technology Limited stands at the forefront of wire harness manufacturing, specializing in the production of a diverse range of products, including wire harness assemblies, wire harnesses, wiring harness solutions, and custom wire harnesses. Our proficiency extends to the meticulous crafting of high quality wire harnesses, featuring protective coverings made from thermoset or thermoplastic materials. These protective sheaths play a pivotal role in safeguarding electric wires from environmental hazards and potential wear and tear.

Distinguished by an unwavering commitment to stringent quality standards, we take pride in delivering custom wire harnesses designed for various applications across industries such as electronic, medical, automotive, telecommunication, military, clean energy, and other high-precision sectors. As a distinguished global contract manufacturer, our innovative solutions cater to the unique needs of original equipment manufacturers (OEMs) and businesses in diverse sectors.

At QL-Custom Technology Limited, our specialization extends to over-molded cable assemblies and wire harnesses, ensuring the highest level of protection for the wires. Our comprehensive range of offerings includes harness assemblies, battery cables, and custom cable assemblies tailored to the specific requirements of our clients.

Bolstered by a dedicated and highly experienced global workforce, we take pride in our leadership in the industry, providing value-added services such as plastic molding, low-pressure molding (PCB over molding), and box-build solutions. Our comprehensive expertise spans various domains, including but not limited to data transmission, crimp terminals, optical fibers, and fiber optics.

Whether it’s meeting the demands of cutting-edge automated driving technologies, facilitating solar equipment installations, or providing solutions for consumer electronics, QL-Custom Technology Limited stands as your trusted partner. We are committed to delivering top-notch wire harness and cable assembly solutions that align with the evolving needs of the industry.

Choose QL-Custom Technology Limited for cutting edge technology, reliable products, and a commitment to excellence in every aspect of wire harness manufacturing. Our extensive array of offerings caters to the unique requirements of various industries, providing solutions for wires, cables, and wire harnesses that meet the highest quality standards.

Our global workforce ensures that we are well-equipped to handle diverse challenges, including environmental hazards. As a global contract manufacturer, we offer value added services, including ultrasonic welding, to meet the intricate demands of our customers. QL-Custom Technology Limited, a name synonymous with quality and innovation in wire harness manufacturing, invites you to experience excellence tailored to your specific needs.

What Is Wire Harness?

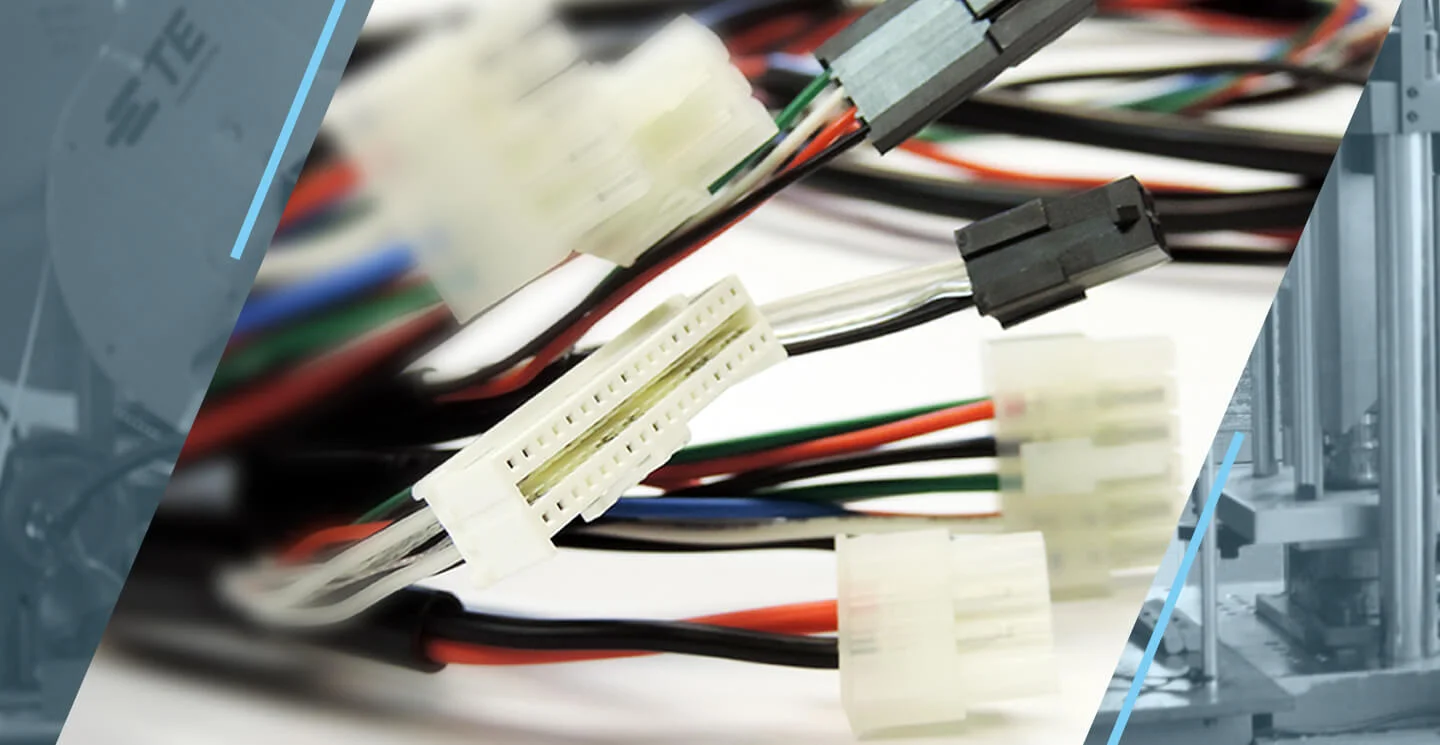

A wire harness, also referred to as a wiring harness, wire harness assembly, or wiring harness assembly, is a comprehensive and organized grouping of electric wires, cables, and associated components that serve the critical purpose of transmitting electrical power and signals within a system or device. These harnesses are meticulously designed to facilitate efficient connectivity while also ensuring organization and protection against environmental hazards.

Wire harnesses find extensive applications across diverse industries, including automotive, aerospace, consumer electronics, solar equipment, and more. They play a pivotal role in interconnecting electrical components, providing a structured pathway for the flow of electricity and signals. Custom wire harnesses are tailored solutions crafted to meet the unique specifications and requirements of original equipment manufacturers (OEMs) operating in different sectors.

These wiring solutions encompass a variety of elements, such as electric wires, battery cables, crimp terminals, optical fibers, and other essential components. The integration of advanced manufacturing techniques, including ultrasonic welding, ensures secure and reliable connections that withstand the challenges posed by environmental conditions.

Benefits Of Wire Harness Solutions

Precision and organization:

- wire harnesses and wiring harnesses ensure organized routing of electric wires, enhancing overall system efficiency.

- QL-Custom’s expertise in harness manufacturing guarantees precision in the arrangement of cables and wires.

Versatility Across Industries:

- Wire harness assemblies cater to a diverse range of industries, including automotive, solar equipment, consumer electronics, and more.

- Custom cable assemblies offer versatile solutions for the unique requirements of different sectors.

Reliable Connectivity:

QL-Custom’s wire harnesses and cable solutions provide reliable connectivity in various applications, ensuring seamless operations.

Harness assemblies contribute to stable electrical connections in critical systems.

Tailored Solutions for OEMs:

- Original equipment manufacturers (OEMs) benefit from wire harnesses designed to meet their specific needs.

- QL-Custom is a trusted partner for OEMs seeking high-quality cable assemblies and wiring solutions.

Efficiency in Data Transmission:

- Fiber optics integrated into wire assemblies support high-speed data transmission in telecommunications and other sectors.

- QL-Custom’s solutions contribute to efficient data transmission, meeting the demands of modern technologies.

Environmental Durability:

- Custom cable assemblies and wire harnesses are designed to withstand environmental conditions, ensuring longevity and reliability.

- Solar equipment installations benefit from durable wiring solutions capable of withstanding various weather conditions.

Seamless Integration in Automated Driving:

- Wire assemblies with crimp terminals play a vital role in the seamless integration of electrical components in automated driving technologies.

- QL-Custom’s solutions contribute to the precision and reliability required for advanced automotive systems.

Global Contract Manufacturing Expertise:

- QL-Custom, as a global contract manufacturer, offers expertise in box build solutions, ensuring comprehensive support for clients worldwide.

- The company’s global workforce is dedicated to delivering high-quality wire harnesses and cable assemblies.

Quality Assurance:

- All wire harnesses, wiring harnesses, and cable assemblies adhere to the highest quality standards set by QL-Custom Technology Limited.

- The commitment to quality ensures that customers receive products that meet or exceed industry expectations.

Value-Added Services:

- QL-Custom goes beyond basic manufacturing, providing value-added services that enhance the overall value of wire harness solutions.

- Customers benefit from comprehensive support, including expert advice and tailored solutions for their specific needs.

Uses Of Wire Harness

Automated Driving Technologies:

- Wire harness assemblies and cable solutions ensure precise data transmission in automated driving systems.

- Custom wire harnesses and cable assemblies with crimp terminals support the complex electrical needs of automated vehicles.

Solar Equipment:

- Wiring harnesses play a crucial role in connecting solar panels, facilitating efficient energy harnessing.

- Custom cable assemblies designed for solar applications ensure reliable connectivity in various environmental conditions.

Consumer Electronics:

- Wire harnesses and cable assemblies are tailored to the intricate requirements of consumer electronic devices.

- Wire harnesses organize electric wires, contributing to the seamless functionality of electronic products.

Telecommunications:

- Fiber optics integrated into wire assemblies enable high-speed data transmission in telecommunications infrastructure.

- Custom cable solutions cater to the specific needs of the telecommunications industry.

Medical Equipment:

- Harness assemblies are used in medical devices, providing organized and reliable electrical connections.

- Wire harnesses contribute to the precision and efficiency of medical equipment.

Clean Energy:

- Wire harnesses play a role in connecting components in clean energy systems, ensuring optimal performance.

- Custom cable assemblies support the diverse electrical requirements of clean energy initiatives.

Diverse Industrial Sectors:

- Wire harnesses find applications in various sectors beyond automotive and electronics.

- QL-Custom, as a global contract manufacturer, offers solutions for original equipment manufacturers (OEMs) in diverse industries.

Data Transmission:

- Fiber optics and wiring harnesses contribute to efficient data transmission in various applications.

- Custom wire harnesses are designed to meet the data transmission needs of different sectors.

Value-Added Services:

- QL-Custom Technology Limited provides value-added services, including box-build solutions, ensuring comprehensive support.

- The global workforce at QL-Custom is committed to delivering excellence and meeting the specific requirements of clients.

Quality Standards:

- All wire harnesses, wiring harnesses, and cable assemblies adhere to the highest quality standards.

- QL-Custom Technology Limited takes pride in the precision and reliability embodied in the company’s products.

Custom Solutions for Other Sectors:

- Custom harnesses and cable assemblies are designed to meet the unique needs of various sectors.

- As a leading contract manufacturer, QL-Custom offers tailored solutions for different industries.

Production Capacity Of The Best Manufacturer

Wire harness manufacturers can work with small and large OEMs; we can handle single-order requests or ongoing production and assembly needs. We can also increase production to meet the needs of our customers, and we have a solid reputation for on-time delivery and fast turnaround, even on custom harness orders.

As with our services, we focus on quality assurance and quality control as a primary aspect of custom wire and cable harness design. The ability to also complete wire harness assembly is an additional benefit to our customers, allowing for faster fabrication and less risk of human error during the on-site wiring of a component, system, or device.

We are different from other custom wire harness manufacturers, and the reasons are:

Our Search For The Best Solution

We have extensive experience working as custom cable assembly manufacturers across a wide range of diverse industries. We provide custom cable assemblies for the agricultural equipment sector, medical device manufacturers, the military, elevators, and industrial controls, to name just a few.

This experience allows our team to identify the best possible solutions in custom cable assemblies to benefit the specific application.

Ability to Deliver On Time

Production deadlines for both small and large-volume orders are always a priority at Assembly Solutions. We have a reputation for delivering to our customers on time and as ordered, ensuring there is never a wait for parts and components from Assembly Solutions.

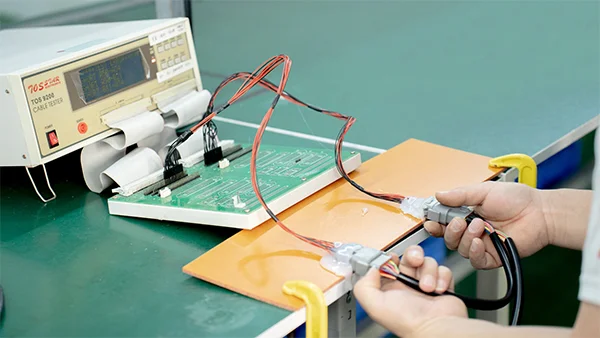

Quality Control And Precision Work

At QL-Custom Technology Limited, our unwavering commitment to quality control and precision work is embedded in every facet of our operations. We specialize in manufacturing harness assemblies, wire harnesses, wiring harnesses, and cable assemblies that adhere to the most rigorous quality standards.

Our dedicated team of experts ensures that each wire harness, wiring harness, and cable assembly meets the exact specifications set forth by our customers.

As leading harness manufacturers and a global contract manufacturer, we take pride in delivering precision-engineered solutions for a diverse range of industries, including original equipment manufacturers (OEMs), solar equipment, consumer electronics, and more.

In our pursuit of excellence, we extend our expertise to wire harnesses and custom cable assemblies, tailoring electrical wiring solutions to the specific needs of our clients. From battery cables to intricate harness assemblies, we meticulously craft products that meet the highest industry standards.

As a company offering value-added services, our commitment to quality extends beyond the manufacturing floor. Our global workforce, well-versed in the intricacies of wire, fibre optics, and data transmission, ensures that our company’s products not only meet but exceed expectations.

Whether it’s automated driving technologies, crimp terminals, optical fibres, or box-build solutions, our comprehensive approach ensures that each component aligns seamlessly with the stringent quality standards we uphold.

Choose QL-Custom Technology Limited for your wire and cable needs and experience the assurance of precision work, reliability, and excellence. Our commitment to quality standards is the cornerstone of the value we bring to clients across various sectors, making us the trusted partner for all your wiring solutions.

Focus On Customer Support

We are also one of the few custom cable assembly manufacturers focusing on customer support and services. Our engineering and design team can work with your in-house team, or we can provide complete engineering and design services, focusing on the lowest possible cost and highest production quality.

QL-Custom, the wire harness company, will work with clients throughout the entire process to produce the designs you desire to your specifications. The quality department will analyse all products using advanced testing apparatus before we quickly deliver the parts to your preferred destination.

We certainly have the ability and capacity to meet virtually any needs you might have about plastic moulding and cable harnesses, relying on our time-tested quality workforce to assure products that will never let you down. We understand the challenges and trends cutting across the electrical design processes across the world, and our engineers are always ready to walk with you in this process.

Our valuable integration resource saves time and costs for global customers thanks to an effective engineering team that is skilled and meticulous, always dedicated to delivering products that meet the highest standards as stipulated by industry standards. You are assured of a quick production process that is executed with precision. The foremost aim is to deliver the best products, and our ability to deliver is based on the following beliefs:

- Excellent customer service: We understand perfectly well that satisfied customers are our number one brand ambassadors.

- A working environment is full of positive energy where we work hard every minute while having some fun along the way.

- We only use approved vendors who are proven to deliver high-quality raw materials because we know that the quality of the final product is just as good as the raw materials that go into making it.

- Fast deliveries globally.

Wire terminals are available in insulated as well as non-insulated. Yet, the insulation provides a protective cover. Therefore, I serve as a non-conductor. Furthermore, the type of project being done will determine if you need insulated or non-insulated terminals.

The insulation shields the wire from water and moisture as well. Also, it protects against extreme heat or cold. Wire insulation is typically available in vinyl, nylon, and heat shrink. Non-insulated terminals provide much more economic value with their low cost. Also, they are commonly used when extra protection is unnecessary.

When purchasing various wire terminals, make sure that your purchase meets industry standards and project requirements.

At present, the automotive wiring harness industry is witnessing product innovations aimed at minimizing the load. Consequently, leading market vendors are using superior grades of conductors, insulators, and sheaths for wires and cables in automotive wiring harness systems.

This assists in enhancing the robustness and high-temperature resistance and protecting the product from any damage. Besides this, they are also developing aluminium harnesses, as aluminium components are utilized for vehicle electrification and minimizing vehicular weight, which, in turn, helps in reducing carbon emissions.

When you need cable wire harnesses for high-performance operation, the team at Ql Custom has the experience and insight to craft the ideal solution. Using your design, our manufacturing experts deliver customised products in line with your project specifications while always maximising efficiency and cost control.

Whether your ultimate goal is aerospace parts, medical equipment, automotive components, marine parts, or something similar, our wiring harnesses offer security and peace of mind in high-stakes settings. Contact Ql Custom today to learn how our state-of-the-art facility and global network of suppliers can meet your precise needs.

Wire harnesses are a mixture of wires that are bundled together to form a wire harness. Wire harnesses range in complexity from a few individual wires going point to point to hundreds of individual wires, multiconductor cables, and welded wires all forming a complex wire harness used to transmit power and all types of data.

Wire harness designs are highly customizable, as harnesses are typically designed to suit specific applications. They may need to be concealed behind walls, fit within electrical boxes, or conform to other space constraints. Precise measurements of the environment, power demand, and lengths must be taken during design to prevent costly mistakes and ensure the proper safety and functionality of the final product.

The harness must fit neatly in its intended space. For example, harnesses in vehicles are very compact to ensure they can fit within the small electrical boxes contained within cars. Outer protective casing size must be taken into consideration.

Wire harnesses often require intricate construction design with mechanical fastening, over-moulded connectors, grommets, strain reliefs, and ultrasonic welds. Types of terminals and how they fit the wire radius are critical decisions during the design.

FAQ

Q1: What is a wire harness, and how is it different from a wiring harness or cable assembly?

A wire harness, also known as a wiring harness or cable assembly, is a collection of wires or cables bound together with protective coverings. While the terms are often used interchangeably, subtle differences may exist. Wire assemblies generally refer to the organized grouping of wires, typically enclosed in protective sheaths, designed for easy implementation into equipment and systems.

Q2: What are the primary applications of wire harnesses and cable assemblies?

Wire harnesses and cable assemblies have diverse applications across industries such as automotive, consumer electronics, telecommunications, medical equipment, clean energy, and more. They play a crucial role in organizing and protecting electric wires, ensuring reliable connectivity and efficient system functionality.

Q3: What sets QL-Custom Technology Limited apart as a wire harness manufacturer?

QL-Custom is a global contract manufacturer specializing in custom wire assemblies and cable solutions. Our expertise extends to various sectors, including original equipment manufacturers (OEMs), solar equipment, consumer electronics, and automated driving. We prioritize precision, reliability, and adherence to the highest quality standards.

Q4: Can QL-Custom provide custom wire harness solutions tailored to specific industry needs?

Yes, QL-Custom specializes in providing wire harnesses and cable assemblies to meet the unique requirements of different industries. Whether it’s automotive applications, solar equipment installations, or telecommunications infrastructure, our solutions are designed to offer optimal performance.

Q5: What are the advantages of using wire harnesses in automated driving technologies?

Wire harness assemblies in automated driving technologies ensure precise and reliable data transmission. The use of crimp terminals and custom cable assemblies supports the complex electrical needs of automated vehicles, contributing to their seamless integration and functionality.