Product Introductie

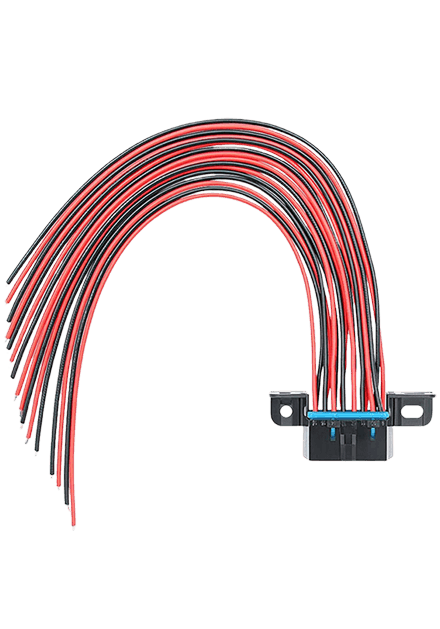

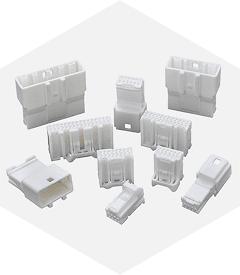

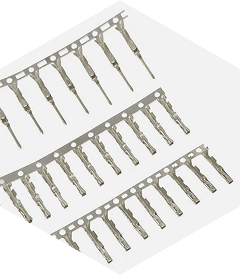

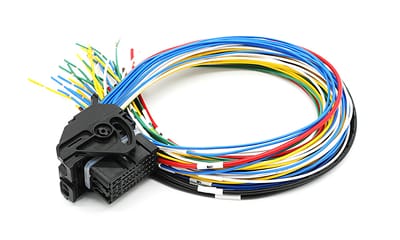

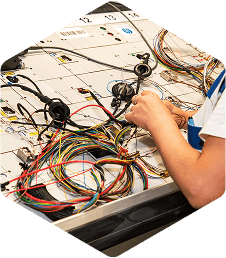

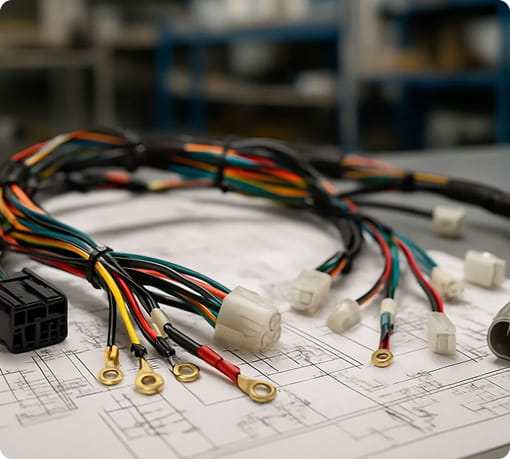

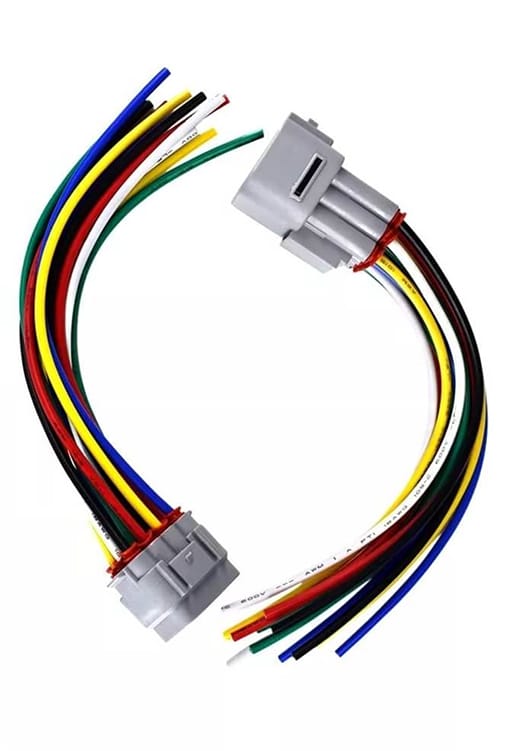

The pigtail wire harness is connected with many wires, and it has a plug on the other side. It connects electric devices together to pass electricity. It mainly keeps all the cables together and makes it easy to use them. There are various cables connected for different works. Each cable has its own color for different work. You can pick the wires by their color easily. The wires are covered with flexible cover materials, which help you to move the cables easily. The harnesses are especially made with hard materials to prevent rough use. There are many options available for wires, jackets or other materials. You can connect the powers and signals easily with these cables smoothly. These cables are excellent for many sections and industries.